Hydraulic pressure type hot water recovery unit

A recovery device, hydraulic technology, applied in the field of hydraulic hot water recovery device, can solve the problems of potential safety hazards, waste of water resources, high power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

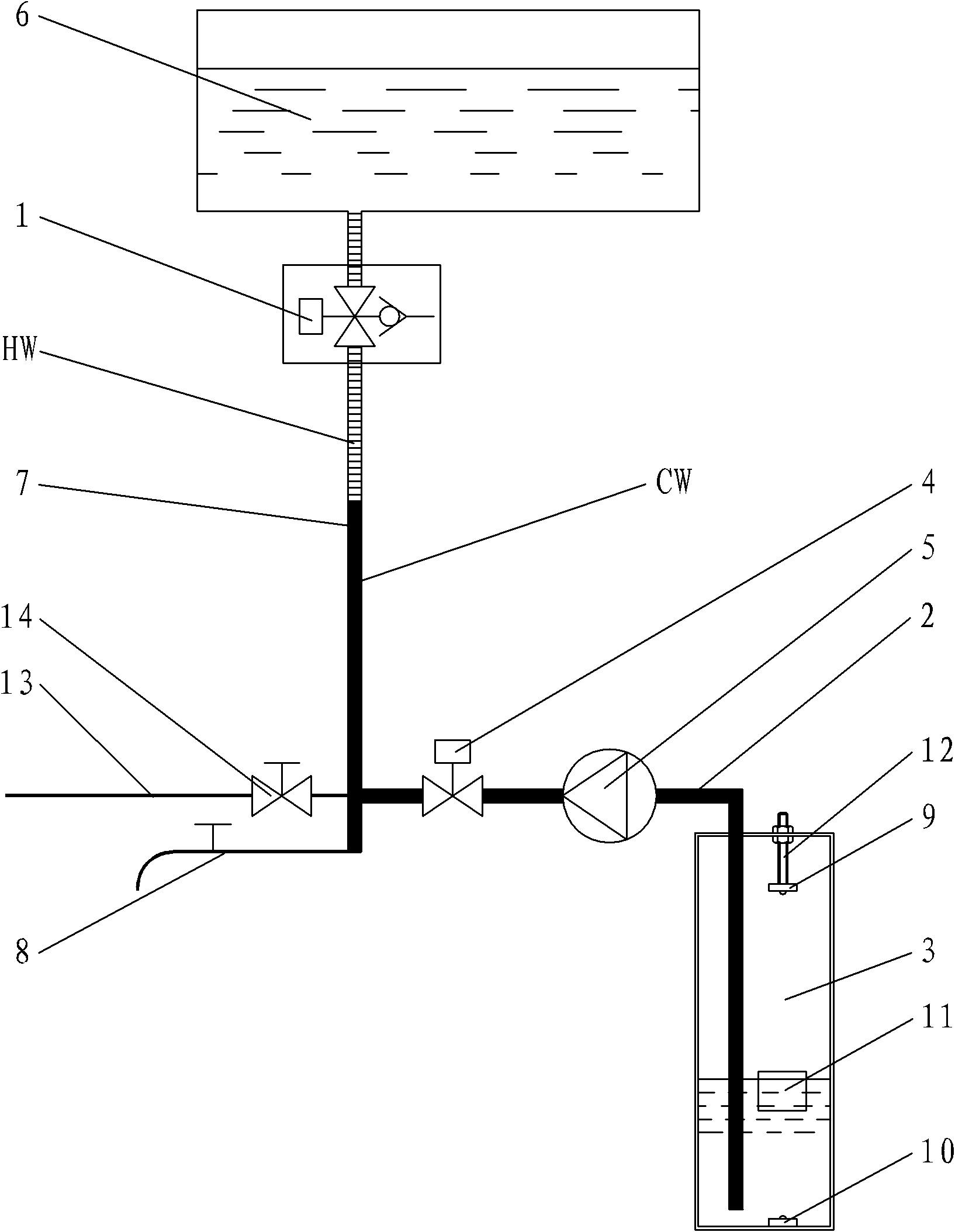

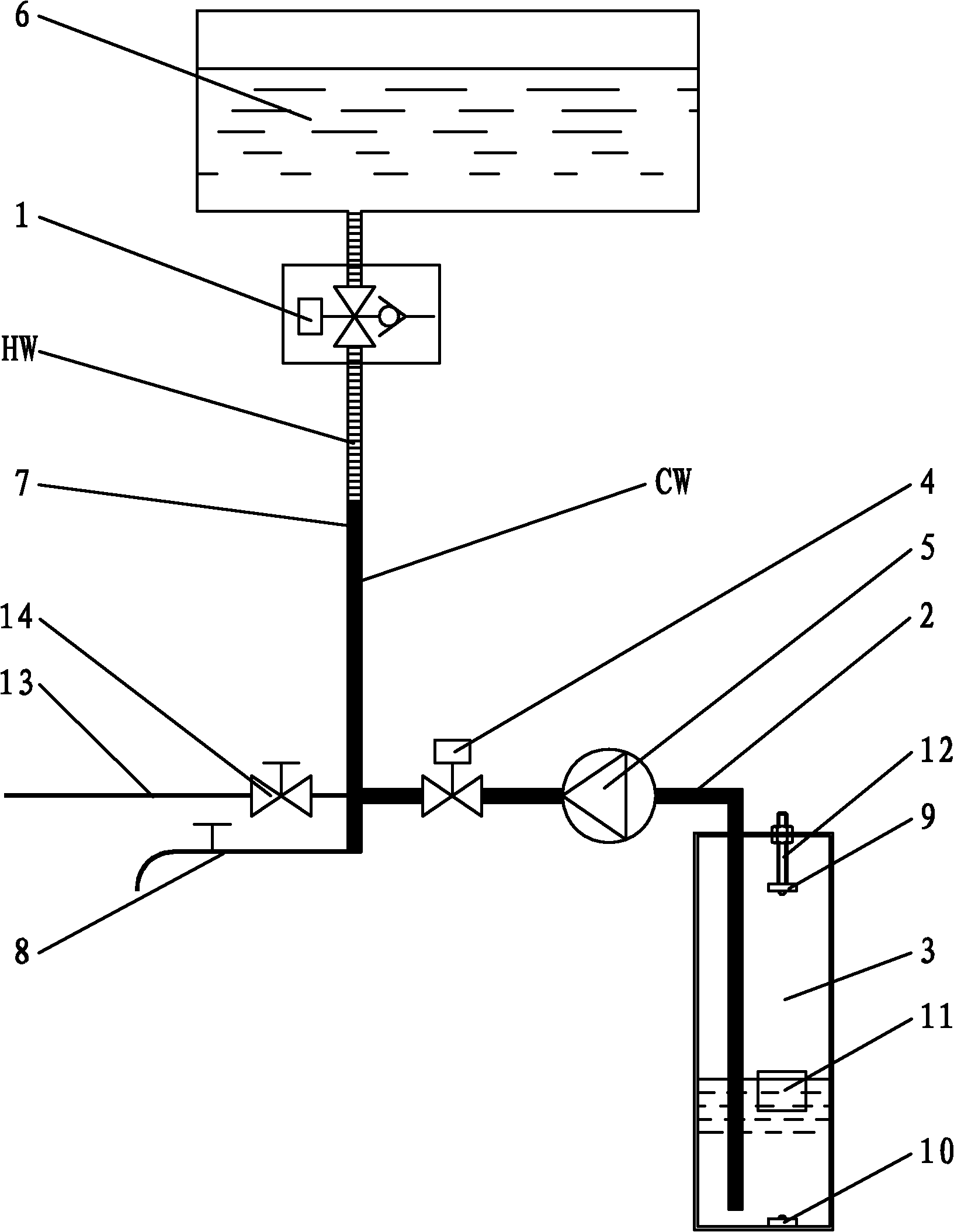

Embodiment 1

[0020] Such as figure 1 As shown, the hydraulic hot water recovery device of the present invention includes an emptying valve 1, a cold water pipe 2, a cold water tank 3, a cold water valve 4 and a water pump 5, and the emptying valve 1 includes three working ports, the first working port and the hot water The tank 6 is connected, the second working port is connected with the water outlet valve 8 through the hot water pipe 7, the third working port is connected with the outside atmosphere, and one end of the cold water pipe 2 is connected to the junction of the hot water pipe 7 and the water outlet valve 8, The other end is arranged in the cold water tank 3, and the water pump 5 and the cold water valve 4 are installed in series on the cold water pipe 2, and the water pump 5 adopts a centrifugal water pump with backflow characteristics. The cold water tank 3 is also externally connected with a water inlet pipe 13, and a water inlet valve 14 is also housed on the water inlet pi...

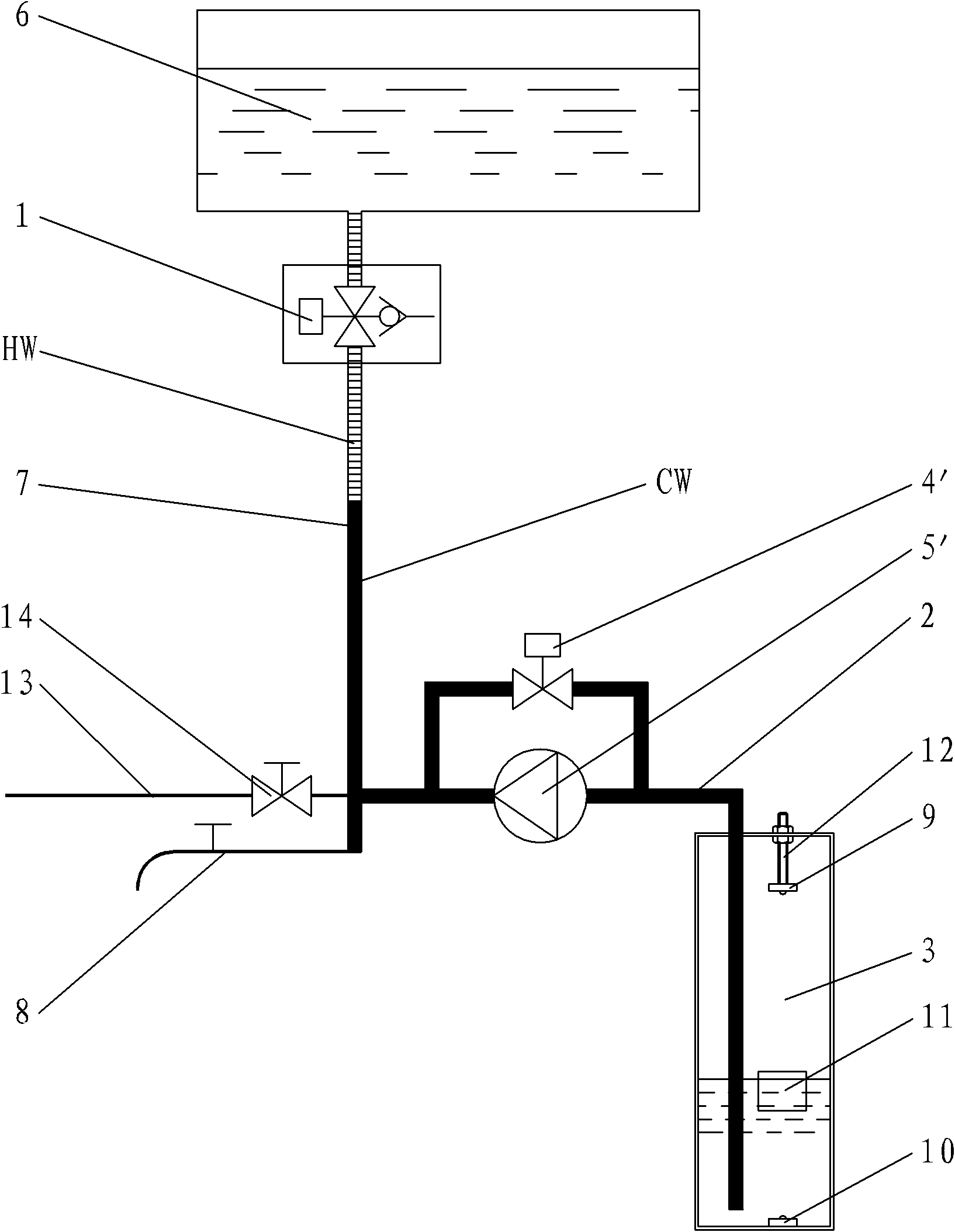

Embodiment 2

[0027] Such as figure 2 As shown, the difference between the second embodiment of the hydraulic hot water recovery device of the present invention and the first embodiment is that the cold water valve 4' and the water pump 5' are installed on the cold water pipe 2 in parallel, and the water pump 5' adopts different Screw pump, piston pump or diaphragm pump with reverse flow characteristic.

[0028] Its working process is also different from the first implementation method:

[0029] When the water outlet valve 8 is opened, the first working port and the second working port of the emptying valve 1 are connected, the third working port is closed, the cold water valve 4' and the water pump 5' are closed, and the hot water HW flows out from the water outlet valve 8;

[0030] When the water outlet valve 8 is closed, the cold water valve 4' is still closed. If hot water needs to be recovered, the water pump 5' is started, and the water pump 5' pumps the cold water CW in the cold wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com