Open fire maintenance method for liquid ammonia pipeline or equipment

A technology for pipelines and equipment, applied in the field of hot maintenance of liquid ammonia pipelines or equipment, can solve problems such as low efficiency, complex maintenance operations, and long time, and achieve the effects of improving work efficiency, outstanding safety performance, and simple operation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

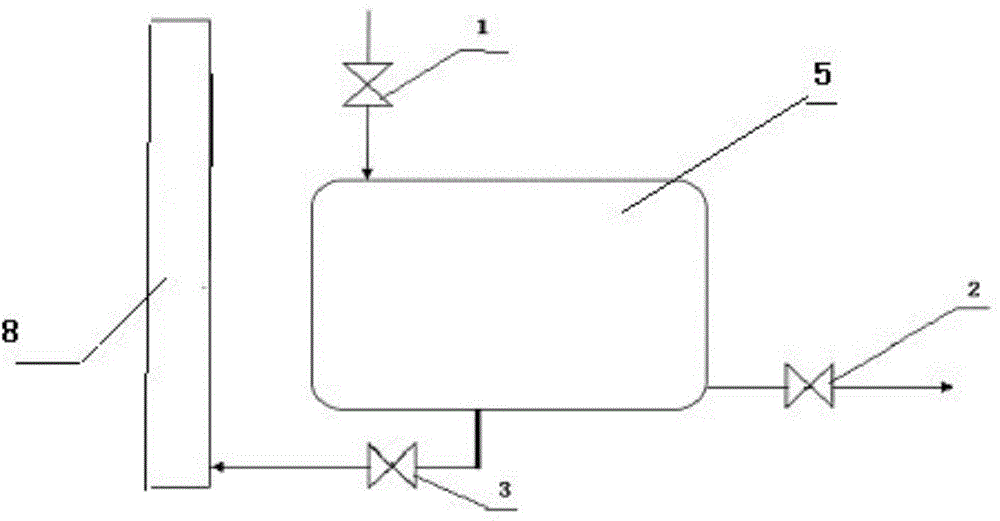

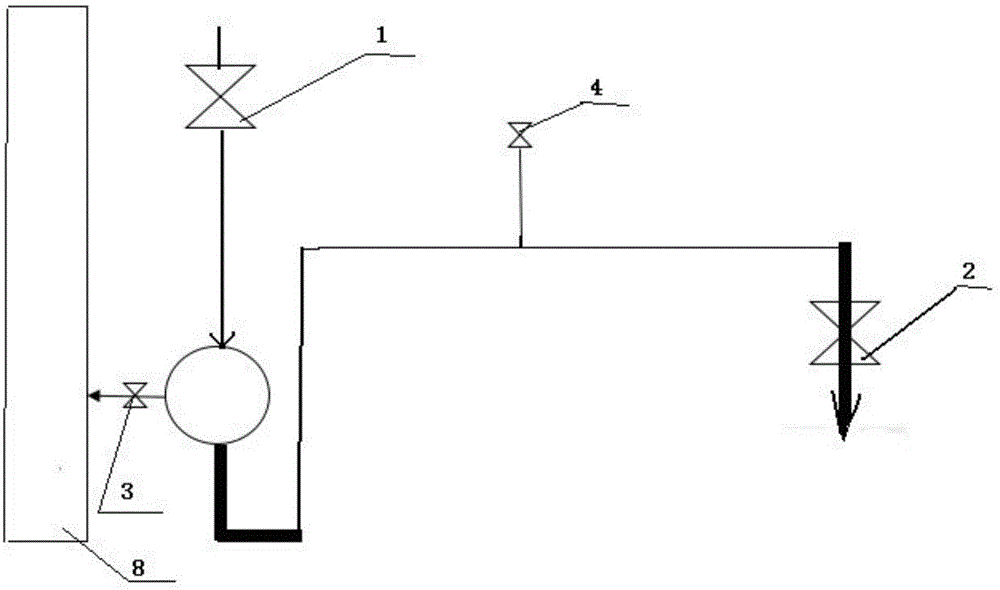

[0034] figure 1 It is a schematic diagram of liquid ammonia transportation, and the liquid ammonia transportation system includes an inlet valve 1 , an outlet valve 2 , an emptying valve 3 and a liquid ammonia transportation pipeline or equipment 5 . figure 2 It is a schematic diagram of liquid ammonia transportation in the embodiment; in April 2013, the 4 roots of the DN15 deluge valve on the main line of the liquid ammonia storage tank area were rusted and perforated to leak ammonia. The hot-fire maintenance method of the present invention was used to successfully carry out the leakage treatment. The specific operations are as follows:

[0035] (1) Close the inlet valve 1 and outlet valve 2, open the exhaust valve 3, introduce the liquid ammonia in the pipeline into the vent tube 8 to discharge and relieve pressure; lead the nitrogen gas to the site for standby with a rubber hose;

[0036] (2) Make a DN50 valved short-circuit 7 with an inner diameter greater than DN15 in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com