Tritium water collecting device

A collection device and technology for tritium water, applied in the field of tritiated water collection and impurity removal devices, can solve the problems of large waste, high cost, low treatment efficiency, etc., and achieve the effects of reducing radioactive waste, prolonging life, and improving adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

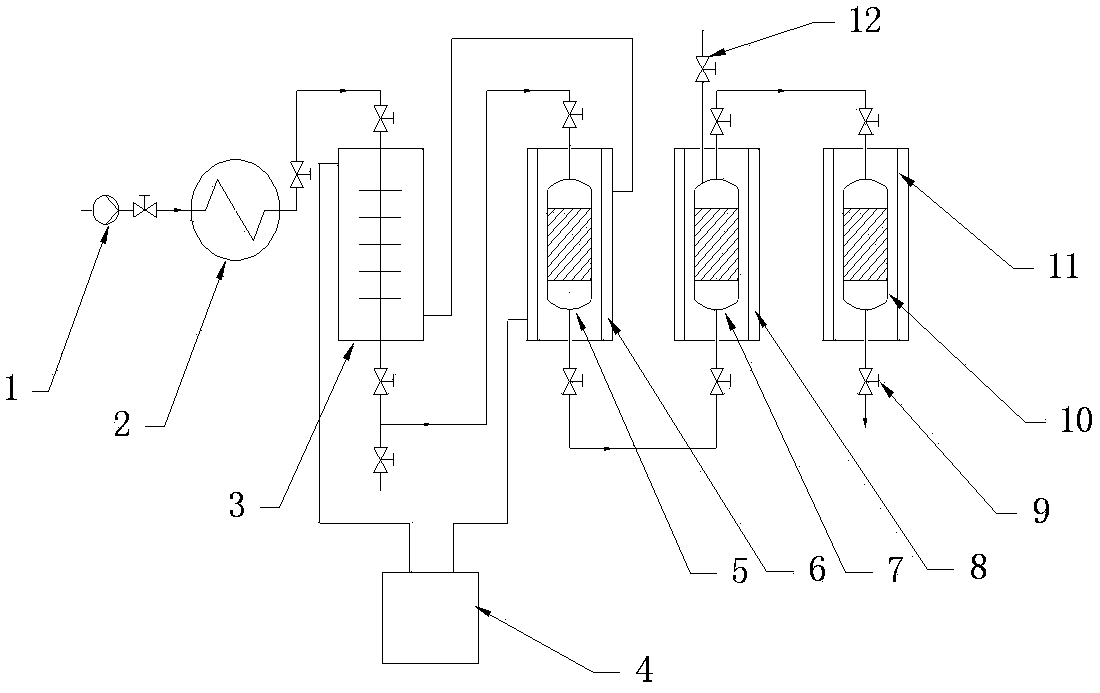

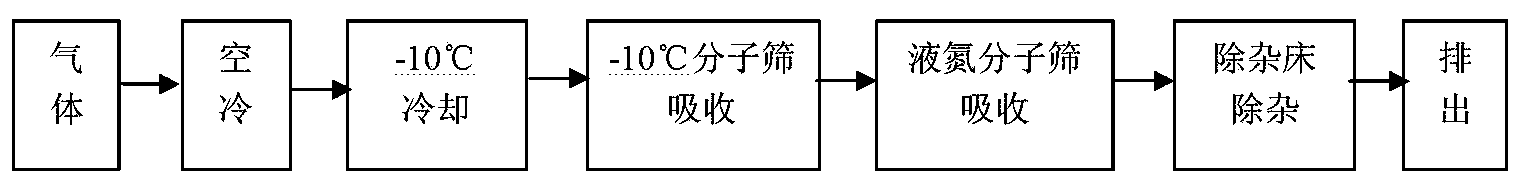

[0023] figure 1 It is a structural schematic diagram of the tritium water collection device of the present invention, and the tritium water collection device of the present invention includes a vacuum booster pump 1, an air cooling coil 2, a cold trap cooler 3, a molecular sieve absorber 5, and a liquid nitrogen temperature molecular sieve absorber 7 , an impurity removal bed 10, a pipeline, an emptying valve, and a control panel that integrates and controls the above-mentioned parts. The connection relationship is that the vacuum booster pump 1, the air cooling coil 2, the cold trap cooler 3, the molecular sieve absorber 5, the liquid nitrogen temperature molecular sieve absorber 7, and the impurity removal bed 10 are sequentially connected through gas pipelines, and the gas Evacuation valves are respectively arranged on the pipelines; wherein, the cold trap cooler 3 and the molecular sieve absorber 5 are respectively connected to the cold trap 4 equipped with coolant through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com