Gas production column for monitoring gas injection driving oil well field aeration zone soil carbon dioxide flux

A carbon dioxide and vadose zone technology, which is used in measurement devices, soil material testing, sampling, etc., can solve the problems of deviation and low measurement accuracy, and achieve the effect of small deviation of monitoring results, comprehensive monitoring information, and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

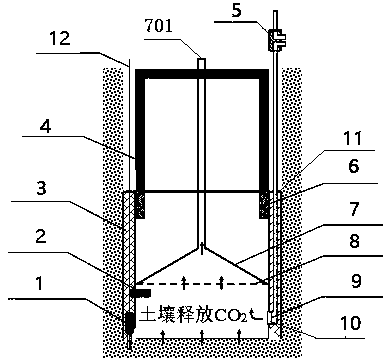

[0021] In order to overcome the problems of deviation in existing monitoring results and low measurement accuracy, the present invention provides a method such as figure 1 The gas production column shown is used to monitor the soil carbon dioxide flux in the gas-filled zone of the gas injection flooding well site. By setting a pressure balance valve in the dynamic gas recovery box, negative pressure is avoided during the gas collection process for measuring the carbon dioxide flux. The formation of the depth positioning rod improves the monitoring accuracy; while the end-to-end overlap of the depth positioning rod can realize the measurement of carbon dioxide flux in the soil layer within a large depth range, and can also simultaneously measure the temperature and soil moisture information at the target point.

[0022] The gas production column used to monitor the soil carbon dioxide flux in the aerated zone of the gas injection flooding well site, including the soil moisture s...

Embodiment 2

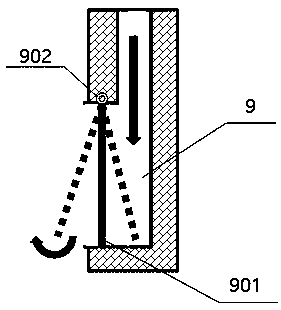

[0026] Based on the above embodiments, in this embodiment, the depth positioning rod 4 is connected to the dynamic gas collection box 3 through an airtight thread 6 .

[0027] The depth positioning rod 4 is made of stainless steel, and the rod body is provided with scales from bottom to top. The length of the depth positioning rod 4 is 1 ~ 3m, and both ends of the depth positioning rod 4 are provided with threaded buttons.

[0028] The depth positioning rod 4 is made of stainless steel, and the rod body is provided with scales from bottom to top, which can intuitively read the setting depth of the dynamic sampling box. The length of the depth positioning rod 4 is 1 ~ 3m, and both ends of the depth positioning rod 4 are provided with threaded fasteners, so that a plurality of positioning rods can be connected end to end to expand the scope of use of the positioning rods.

[0029] The dynamic gas collection box 3 is made of plexiglass material, with a thickness of 15-20mm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com