Repeated foaming device for gathering and delivering pipeline of foam drainage gas-production well

A foam drainage and gas recovery technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve problems such as liquid accumulation in pipelines, serious gas-liquid stratification, and blockage of gathering and transportation pipelines, so as to avoid pipeline blockage , reduce mining costs, and reduce the effect of gas-liquid stratification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

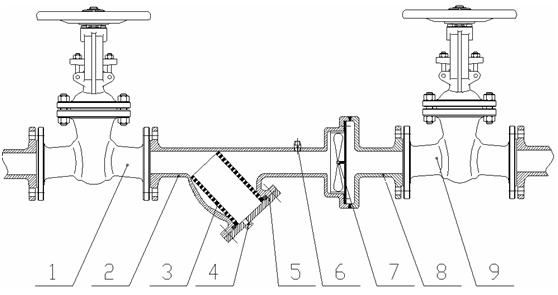

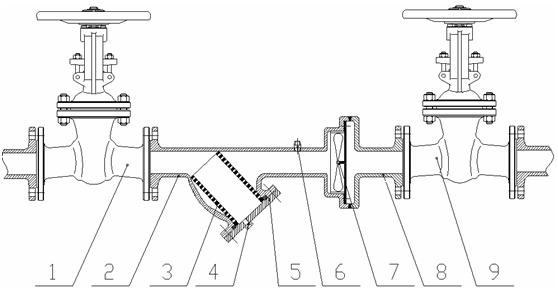

[0012] According to the drawings, one end of the inlet gate valve 1 of a foaming exhaust well collection and transportation pipeline is connected to the upstream collection and transportation pipeline with a flange; the other end of the inlet gate valve 1 is connected to the device shell A2 through a flange; There is a flange cover 5 under the device housing A2, and a drain valve 4 is installed on the flange cover 5. One end of the filter cartridge 3 is placed at the inlet end of the device housing A2, and the other end is placed on the drain valve in the device housing A2. 4, the solid-phase impurities in the collection and transportation pipeline are filtered through the filter cartridge 3, and the filtered solid-phase impurities can be discharged by the sewage valve 4; a hydraulic quick joint 6 is installed above the device housing A2, and the foaming agent outside the collection and transportation pipeline is injected The equipment can inject foaming agent into the collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com