Compact-type natural gas compressor

A natural gas and compressor technology, applied in the field of compact natural gas compressors, can solve the problems of high energy consumption and no improvement, and achieve the effects of long equipment service life, high exhaust pressure and small equipment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in combination with specific embodiments.

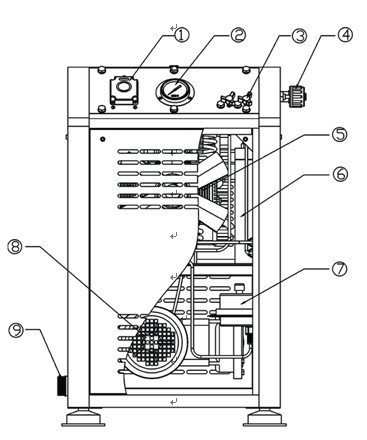

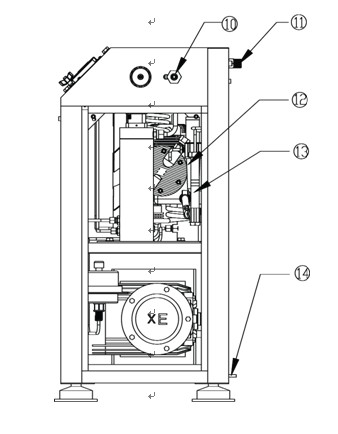

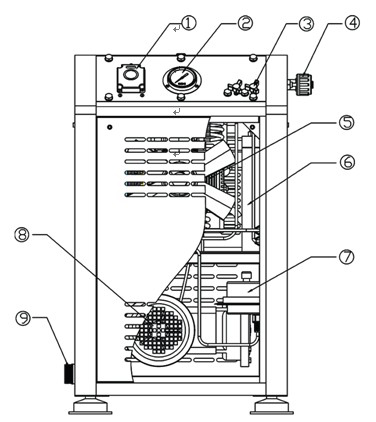

[0015] A blowdown valve 3, a shut-off valve 4, a power connector 9, an air filling port 10, an air inlet 11 and a sewage pipe 14 are installed on the outer wall of the case, and a machine head 5, a filter cartridge 6, an explosion-proof motor 8, and an oil-water separator 12 are installed in the case. The air inlet 11 is connected to the filter cartridge 6, machine head 5, oil-water separator 12 and air charging port 10 in turn, the explosion-proof motor 8 is connected to the machine head 5, the sewage pipe 14 is connected to the oil-water separation gas 12 or the filter cartridge 6, and the sewage valve 3 is connected to the filter cartridge 6. Sewage pipe 14 is connected.

[0016] An emergency button 1, a pressure gauge 2 and a stop valve 4 are installed on the outer wall of the case.

[0017] The machine head 5 is a four-stage reciprocating piston compression cylinder w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com