Vacuum heat pump drying device

A drying device and vacuum heating technology, applied in the drying of solid materials, local stirring dryers, and static materials dryers, etc., can solve the problems of not inhibiting the growth of bacteria and microorganisms, affecting product quality, and high cost, and shortening the drying time. , low cost, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

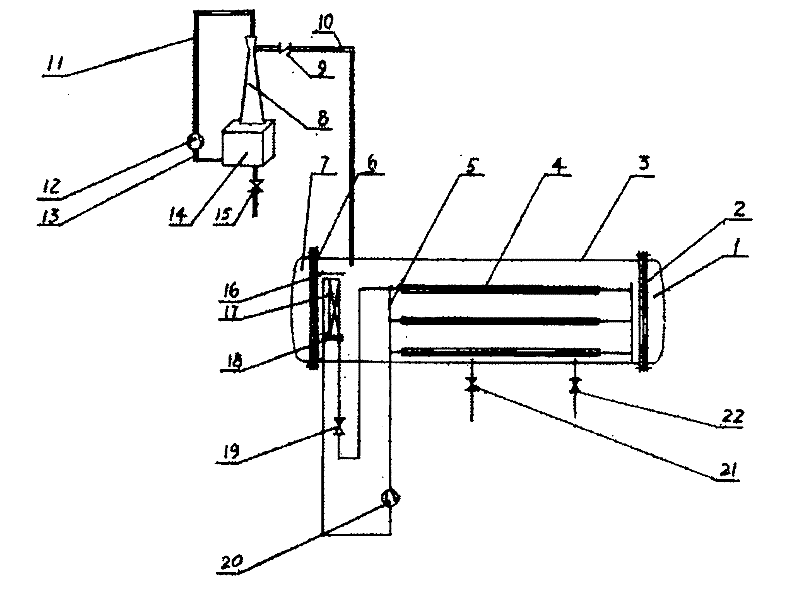

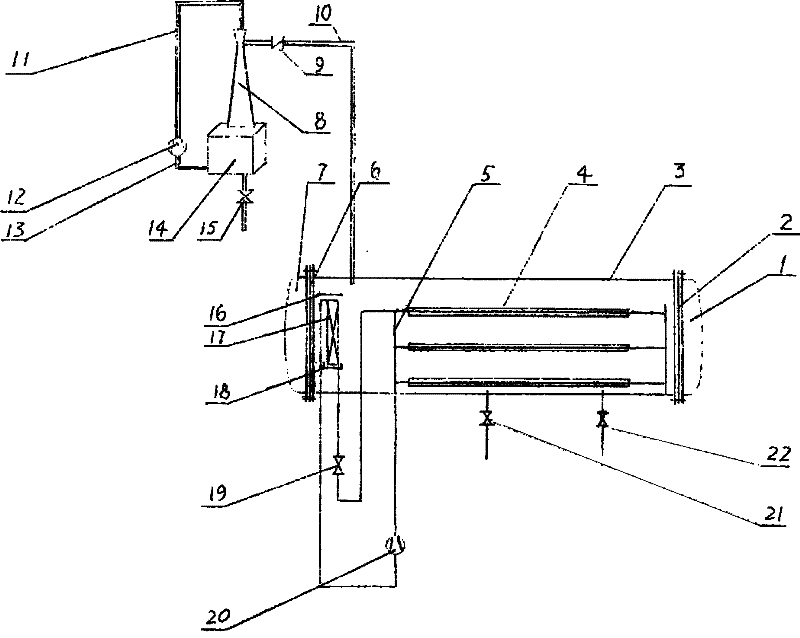

[0007] The present invention is illustrated below by way of examples and accompanying drawings.

[0008] The vacuum heat pump drying device of the present invention has a drying box body 3, and its left and right ends have left and right end caps 7, 1 and left and right sealing strips 6, 2 respectively, and the condenser plate for exothermic heat of the heat pump is housed in the drying box body 3 The tube 5 and the evaporator coil hanger 16, the evaporator coil 17 and the water receiving tray 18 for the heat pump to absorb heat are installed on the evaporator coil hanger 16. The compressor 20 of the heat pump and the throttle valve 19 are arranged on the outside of the drying box body 3. The inlet and outlet of the compressor 20 are connected with the outlet of the evaporator coil 17 and the inlet of the condenser coil 5 respectively. , and the outlet communicate with the outlet of the condenser coil 5 and the inlet of the evaporator coil 17 respectively. The inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com