Treating device and treating process for waste gas produced in pyrolysis of waste rubber and plastics

A waste gas treatment device, rubber and plastic technology, applied in the direction of gas dust removal, petroleum industry, combustible gas purification, etc., can solve the problems of waste of recyclable energy, large loss of water resources, complex devices, etc., to achieve small footprint and low investment Low cost, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

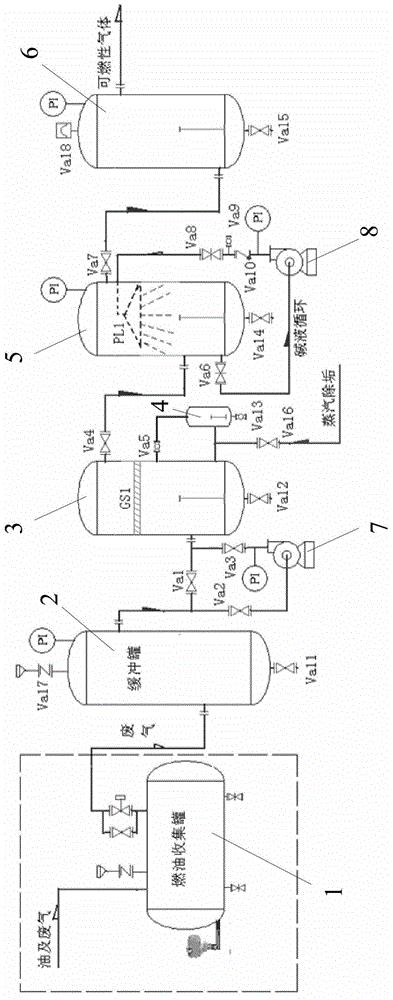

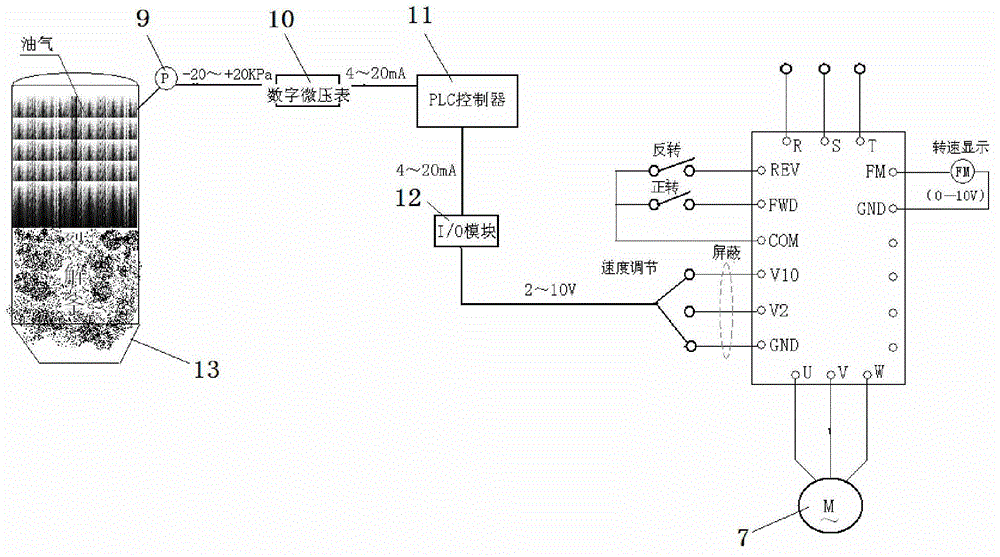

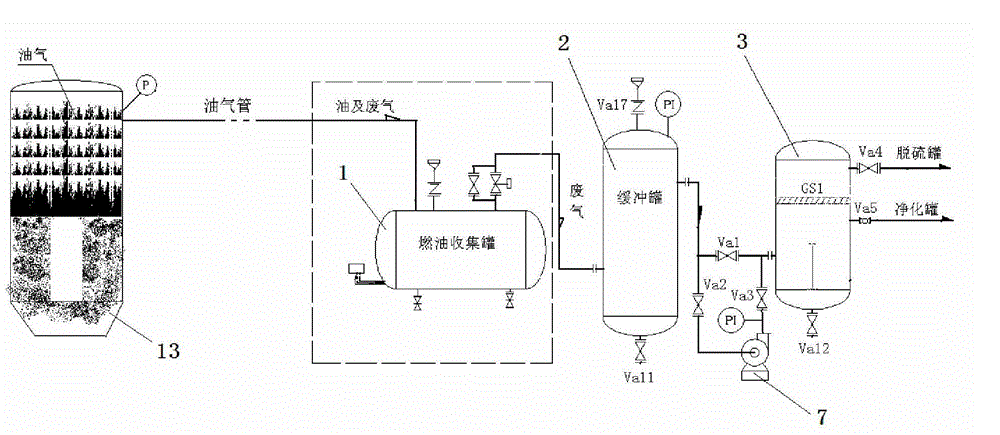

[0036] Such as figure 1 As shown, the present invention provides an exhaust gas treatment device in the cracking of waste rubber and plastics. The device includes a buffer tank 2, a liquid separation tank 3, a purification tank 4, a desulfurization tank 5, a safety tank 6, a vacuum pump 7, and a corrosion-resistant pump 8. , The second to eighth stop valve Va2-Va8, ball valve Va9, gate valve Va10, first to fifth drain valves Va11-Va15, steam valve Va16, gas breathing apparatus Va17, and explosion-proof device Va18;

[0037] The buffer tank 2 is used to collect waste gas, and the buffer tank 2 is connected to the liquid separation tank 3 via the second shut-off valve Va2, the vacuum pump 7, and the third shut-off valve Va3, so that the waste gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com