Gas field foam drainage agent

A foam drainage agent and gas field technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of general foam stability, inability to be effectively discharged, poor foam discharge effect, etc., and achieve the goal of increasing toxicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

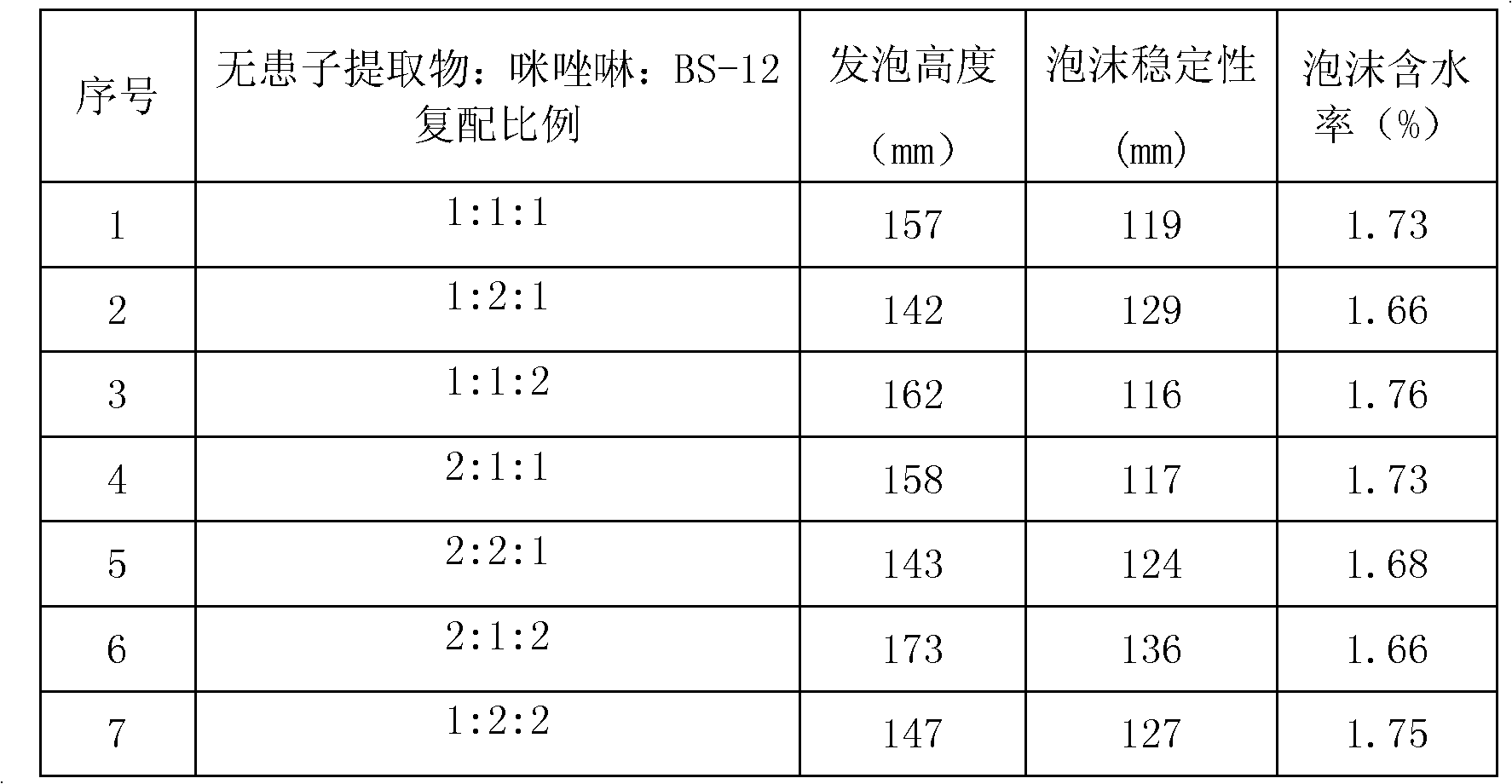

Examples

Embodiment 1

[0014] The gas field foam drainage agent of the present embodiment is made up of the following components by weight: 95 parts of surfactants, 3 parts of methylcellulose, 5 parts of DC-7 foam control agents (Dow Corning), wherein surfactants are made of Sapindus chinensis extract, imidazoline and dodecyl dimethyl betaine are composed according to the weight ratio of 1:2:2. Wherein the extraction method of Sapindus chinensis extract is as follows:

[0015] Take Socceria chinensis and crush it into small pieces of 1 cm, add water and soak at 80°C for 36 hours, then add flocculant aluminum sulfate to flocculate for 12 hours, take the supernatant liquid and concentrate it under reduced pressure to 5wt% water content to obtain the Sagittarius Extract.

Embodiment 2

[0017] The gas field foam drainage agent of the present embodiment is made up of the following components by weight: 100 parts of surfactants, 5 parts of methyl cellulose, 7 parts of DC-7 foam control agents (Dow Corning), wherein the surfactants are made of The sapinsia extract, imidazoline and dodecyl dimethyl betaine are composed according to the weight ratio of 2:1:2. Wherein the extraction method of Sapindus chinensis extract is as follows:

[0018] Take Socceria chinensis and crush it into small pieces of 3 cm, add water and soak for 72 hours at 100°C, then add flocculant aluminum sulfate to flocculate for 18 hours, take the supernatant liquid and concentrate it under reduced pressure to 3wt% water content to obtain Sagittarius Extract.

Embodiment 3

[0020] The gas field foam drainage agent of the present embodiment is made up of the following components by weight: 105 parts of surfactants, 7 parts of methyl cellulose, 10 parts of DC-7 foam control agents (Dow Corning), wherein surfactants are made of Sapindus chinensis extract, imidazoline and dodecyl dimethyl betaine are composed according to the weight ratio of 2:2:1. Wherein the extraction method of Sapindus chinensis extract is as follows:

[0021] Take Socceria chinensis and crush it into small pieces of 2 cm, add water and soak at 90°C for 48 hours, then add flocculant aluminum sulfate to flocculate for 24 hours, take the supernatant liquid and concentrate it under reduced pressure to contain 1 wt% of water, to obtain Sagittarius Extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com