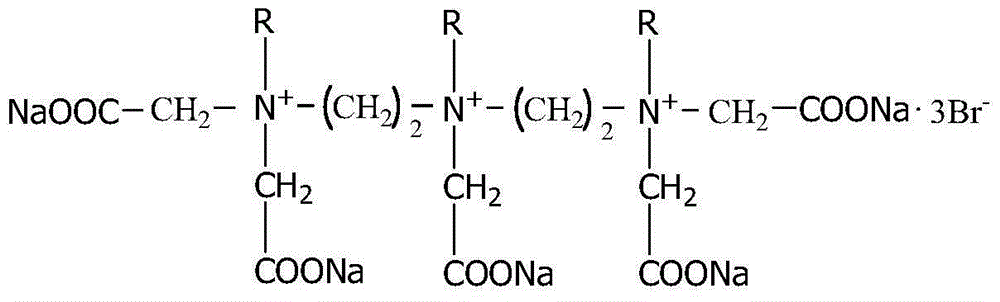

Oligomeric betanine type foam drainage agent and preparation method

A technology of foam drainage agent and betaine, which is applied to the preparation of cyanide reaction, chemical instruments and methods, and the preparation of organic compounds. High practical value, high surface activity, and easy on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

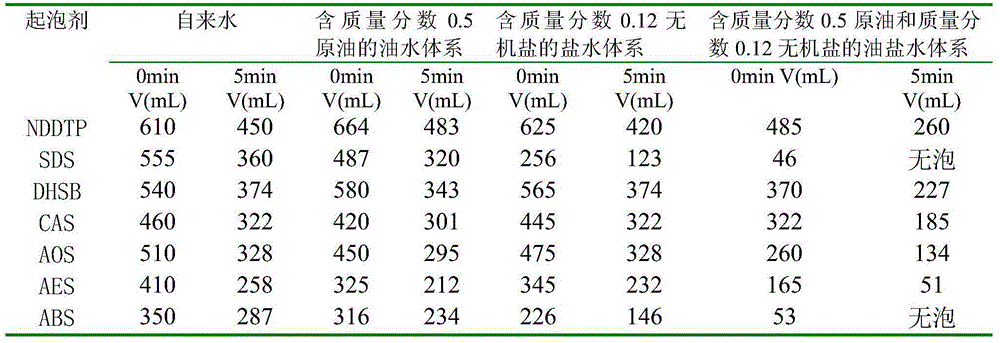

Examples

Embodiment Construction

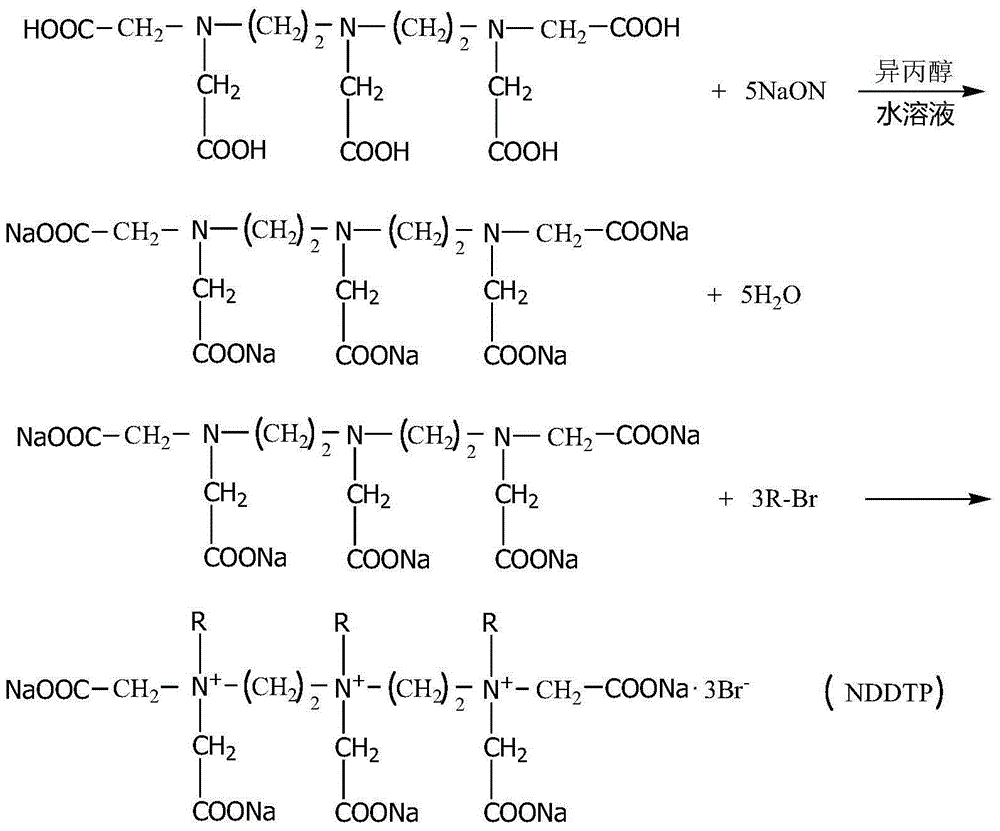

[0016] The concrete implementation method of this invention and the test result of product performance are illustrated below in conjunction with technical scheme of the present invention:

[0017] Example 1 In a 10L reactor equipped with a stirrer, a reflux condensing device and a dropping funnel, slowly add 0.5mol sodium hydroxide dropwise to 4L of isopropanol aqueous solution (the volume ratio of isopropanol to water is 3:1), Start the stirring device, heat slowly, and raise the temperature to 65°C until the sodium hydroxide is completely dissolved, then add 0.1mol of diethylenetriaminepentaacetic acid to the above solution, control the temperature at 70°C, and finish the reaction for 15 minutes until a colorless Clear solution to obtain the intermediate product sodium diethylenetriaminepentaacetate. Then dissolve 0.32mol of bromododecane in 1L of n-propanol, and slowly add it dropwise to the above-mentioned unseparated intermediate product, sodium diethylenetriaminepentaace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com