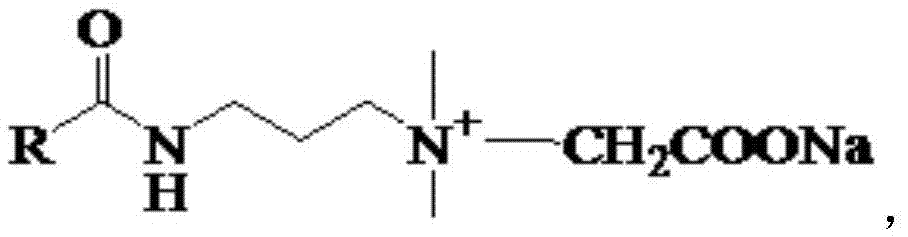

Fatty acid amide propyl betaine foam scrubbing agent as well as preparation method and application thereof

A technology of fatty acid amidopropyl betaine and fatty acid, which is applied in the field of fatty acid amidopropyl betaine foaming agent and its preparation, and achieves the effect of simple process, excellent performance and good foam stabilizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

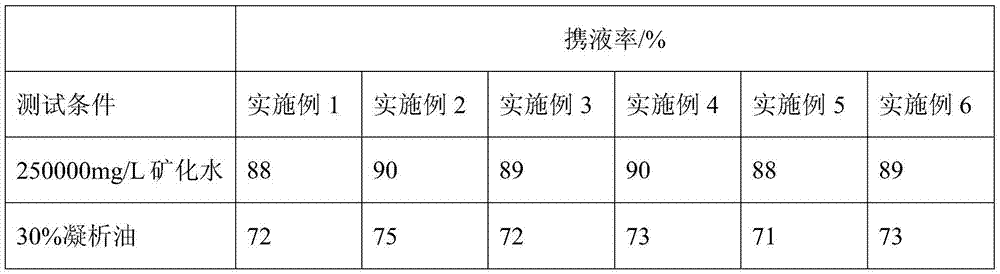

Examples

Embodiment 1

[0029] In a reactor with a reflux condenser, add 0.5 mol of lauric acid, 0.25 mol of coconut oleic acid, and 0.25 mol of oleic acid in a molar ratio of 2:1:1, add N,N-dimethyl-1, About 1.05mol of 3-propanediamine, 1.28g of potassium hydroxide as a catalyst, conduct condensation reaction at 160°C for 4h, test that the content of free fatty acid is less than or equal to 2%, after the reaction is completed, cool and place overnight to obtain the intermediate product long-chain alkyl tertiary amine ; Weigh 1.0mol of the long-chain alkyl tertiary amine prepared in the first step, add 1.05mol of sodium chloroacetate, and add it to solvent water to form a 35% solution. Nucleophilic substitution reaction occurs at 60°C for 6 hours, and the content of free amine is less than 0.5%, the fatty acid amidopropyl betaine is obtained after the reaction, which is the main agent of the foaming agent resistant to high salinity and condensate oil.

Embodiment 2

[0031] In a reactor with a reflux condenser, add 0.5 mol of lauric acid, 0.25 mol of coconut oleic acid, and 0.25 mol of oleic acid in a molar ratio of 2:1:1, add N,N-dimethyl-1, About 1.05mol of 3-propanediamine, 1.5g of potassium hydroxide as a catalyst, conduct condensation reaction at 140°C for 4 hours, test that the free fatty acid content is less than or equal to 2%, after the reaction is completed, cool and place overnight to obtain the intermediate product long-chain alkyl tertiary amine ; Weigh 1.0 mol of the long-chain alkyl tertiary amine prepared in the first step, add 1.05 mol of sodium chloroacetate, add it to water to form a 35% solution, nucleophilic substitution reaction occurs at 90°C for 3 hours, and the free amine content is tested to be less than 0.5% At the end of the reaction, fatty acid amidopropyl betaine is obtained, which is the main agent of the foaming agent resistant to high salinity and condensate oil.

Embodiment 3

[0033] In a reactor with a reflux condenser, add 0.5 mol of lauric acid, 0.25 mol of coconut oleic acid, and 0.25 mol of oleic acid in a molar ratio of 2:1:1, add N,N-dimethyl-1, About 1.10mol of 3-propanediamine, 1.7g of potassium hydroxide as a catalyst, conduct condensation reaction at 140°C for 3.5h, test that the free fatty acid content is less than or equal to 2%. Amine: Weigh 1.0 mol of the long-chain alkyl tertiary amine prepared in the first step, add 1.05 mol of sodium chloroacetate, add it to water to form a 35% solution, nucleophilic substitution reaction occurs at 70°C for 5 hours, and the free amine content is less than 0.5 %, the reaction is completed to obtain fatty acid amidopropyl betaine, which is the main agent of foaming agent resistant to high salinity and condensate oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com