Gas field foam water drainage bar and preparation method thereof

A foam drainage and gas field technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of reduced foaming performance and liquid-carrying performance, inability to meet on-site use, etc., and achieves improved foaming effect and simplified drilling. The medicine operation process, the effect of high foaming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

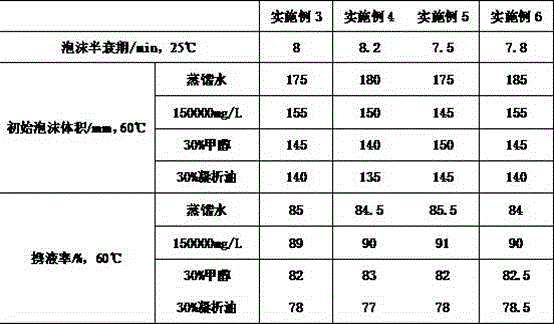

Examples

Embodiment 1

[0029] This embodiment provides a gas field foam drainage rod, and the gas field foam drainage rod is made of the following components by mass percentage:

[0030] Fatty acid betaine derivatives 80~95%, fatty acid betaine derivatives are lauric acid amidopropyl betaine, coco amidopropyl betaine, cis-9-octadecenoic acid aminopropyl betaine, lauric acid imidazole One or more of phenoline betaine and cis-9-octadecenoic acid imidazoline betaine are mixed in any proportion, and the aqueous solution mixture is obtained through powder spraying and drying to obtain a solid powder;

[0031] Polyvinyl alcohol 0.1-5%, polyvinyl alcohol is one of polyvinyl alcohol 1755, polyvinyl alcohol 1788, polyvinyl alcohol 2455, polyvinyl alcohol 2488, soluble polyvinyl alcohol fiber;

[0032] Polyvinylpyrrolidone 0.01-1.0%, the polyvinylpyrrolidone model is K30, and the polyvinylpyrrolidone is a solution dissolved in a mixed solvent of ethanol and water, wherein the volume ratio of the mixed solvent...

Embodiment 2

[0036] This embodiment provides a method for preparing a gas field foam drainage rod, and the preparation process is as follows:

[0037] Step 1: spraying and drying the fatty acid betaine derivative solution to obtain a solid powder;

[0038] Step 2: Mix the solid powder obtained in step 1 with polyvinyl alcohol and sodium carboxymethyl cellulose in a blender in proportion, and the fatty acid betaine derivatives, polyvinyl alcohol and sodium carboxymethyl cellulose in the obtained mixture The mass-number ratio is 60-90 parts: 0.1-5 parts: 0.1-5 parts;

[0039] Step 3: Dissolving the polyvinylpyrrolidone in a mixed solvent of ethanol and water, the mass ratio of polyvinylpyrrolidone is 0.01 to 1.0 parts, and then evenly spraying on the solid surface in step 3, wherein the volume ratio of the mixed solvent of ethanol and water is V 乙醇 :V 水 =5~9:1, the dissolved concentration of polyvinylpyrrolidone is 0.1~5wt%;

[0040] Step 4: After the mixture in Step 3 is bonded, transfer...

Embodiment 3

[0043] Weigh 6000g lauric amidopropyl betaine (30%wt), 1500g cocoamidopropyl betaine (30%wt), 1400g cis-9-octadecenoylaminopropyl betaine (30%wt) , 500g of imidazoline laurate betaine (30%wt) were mixed evenly, and spray-dried by a spray dryer to obtain white powder betaine; V (ethanol): V (water) = 6:1 was used as a solvent to prepare 1% polyethylene pyrrolidone solution.

[0044] Weigh 900g of the above-mentioned powder betaine, add 45g of polyvinyl alcohol 1755, 30g of sodium carboxymethylcellulose, 15g of soluble polyvinyl alcohol fiber (length 4-6mm), 10g of 1% polyvinylpyrrolidone solution, according to the method of Example 2 , made into a diameter of 40mm and a length of 400mm, and vacuum-dried at 50°C to obtain a foam drainage rod.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com