Pneumatic tire

A technology for pneumatic tires and treads, which is applied in the direction of pneumatic tires, tire parts, tire treads/tread patterns, etc., and can solve problems such as inability to configure transverse grooves, difficulty in obtaining tire overall balance, and obvious high-frequency noise. To achieve the effect of improving uneven wear resistance, improving drainage, and reducing high-frequency noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

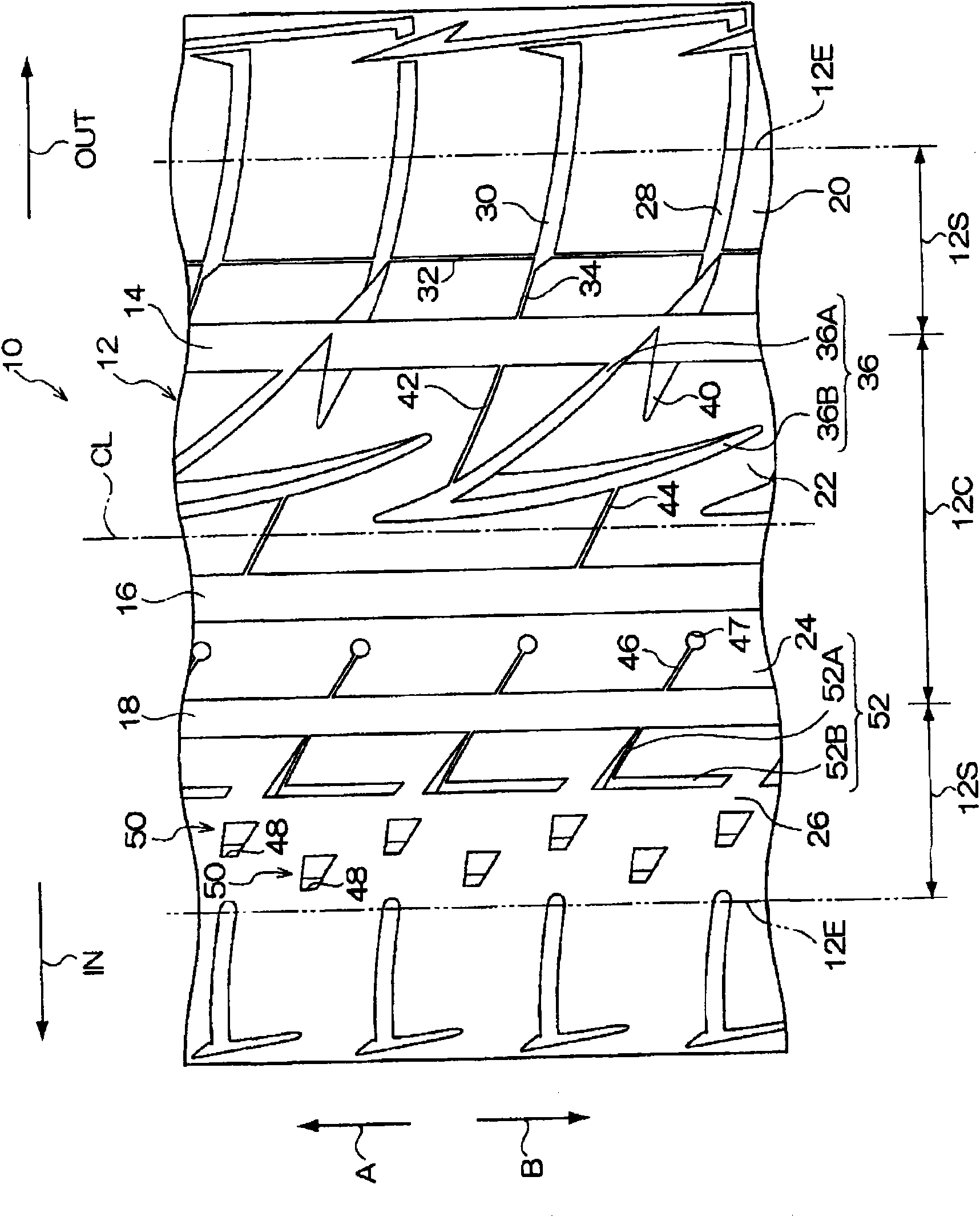

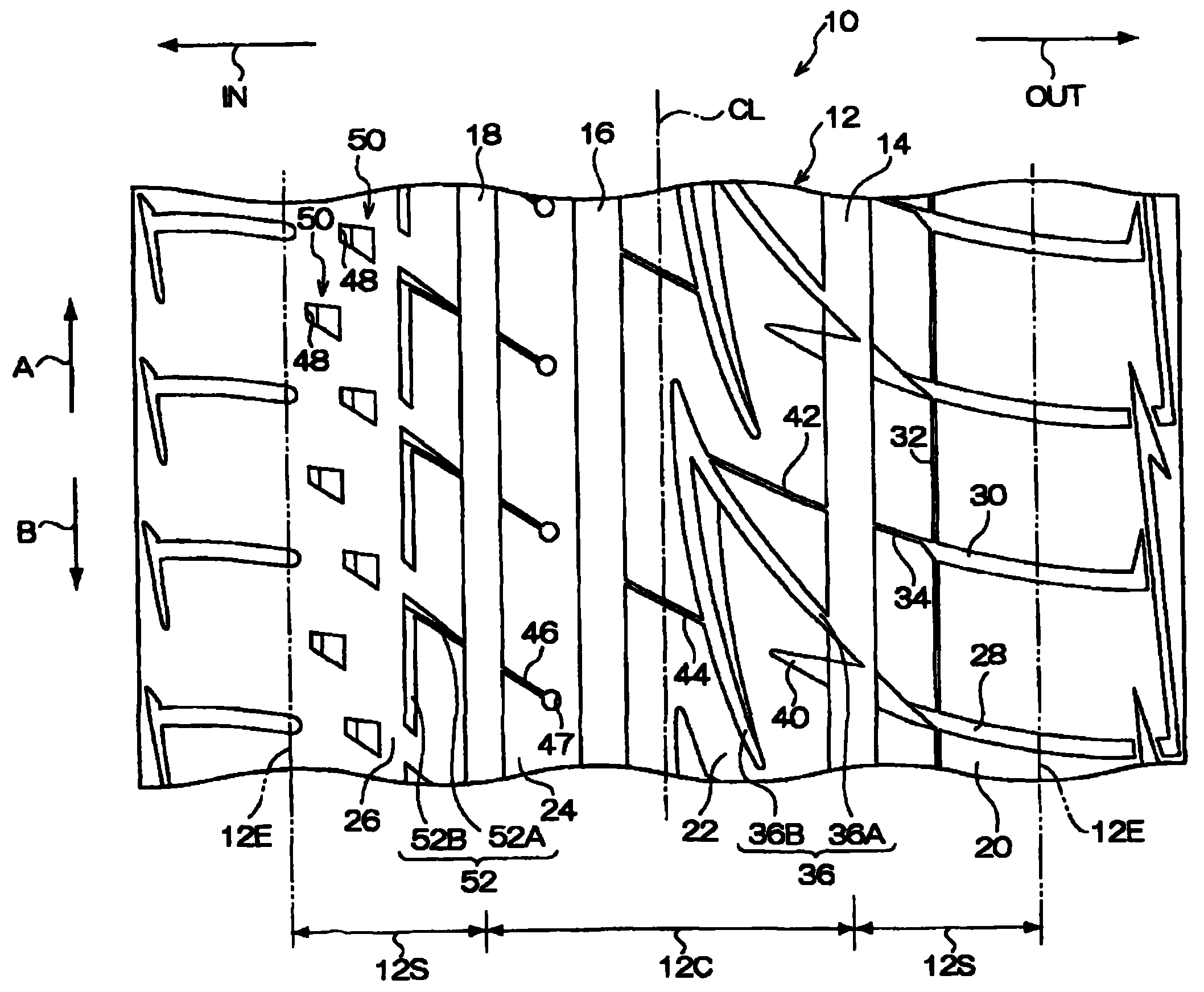

[0078] The fourth land portion 26 on the innermost side when mounted on a vehicle is a land portion that requires severe uneven wear. 90°, the rigidity of the fourth land portion 26 can be ensured, and the uneven wear resistance of the fourth land portion 26 can be improved.

Embodiment

[0081] Example: It is a pneumatic tire having the tread pattern of the above-mentioned embodiment. In addition, its groove depth is 8.3 mm. The groove width of the first circumferential main groove was 8.5 mm, the groove width of the second circumferential main groove was 9.0 mm, and the groove width of the third circumferential main groove was 7.5 mm. The width of the first land portion was 30 mm, the width of the second land portion was 35 mm, the width of the third land portion was 13.2 mm, and the width of the fourth land portion was 32 mm. On the other hand, the inclination angle of the V-shaped groove is 45° on the main groove side in the first circumferential direction, and is 30° near the curved portion. Furthermore, the circumferential pitch length of the V-shaped grooves is 58 mm, and the circumferential pitch length of the L-shaped grooves is 28 mm.

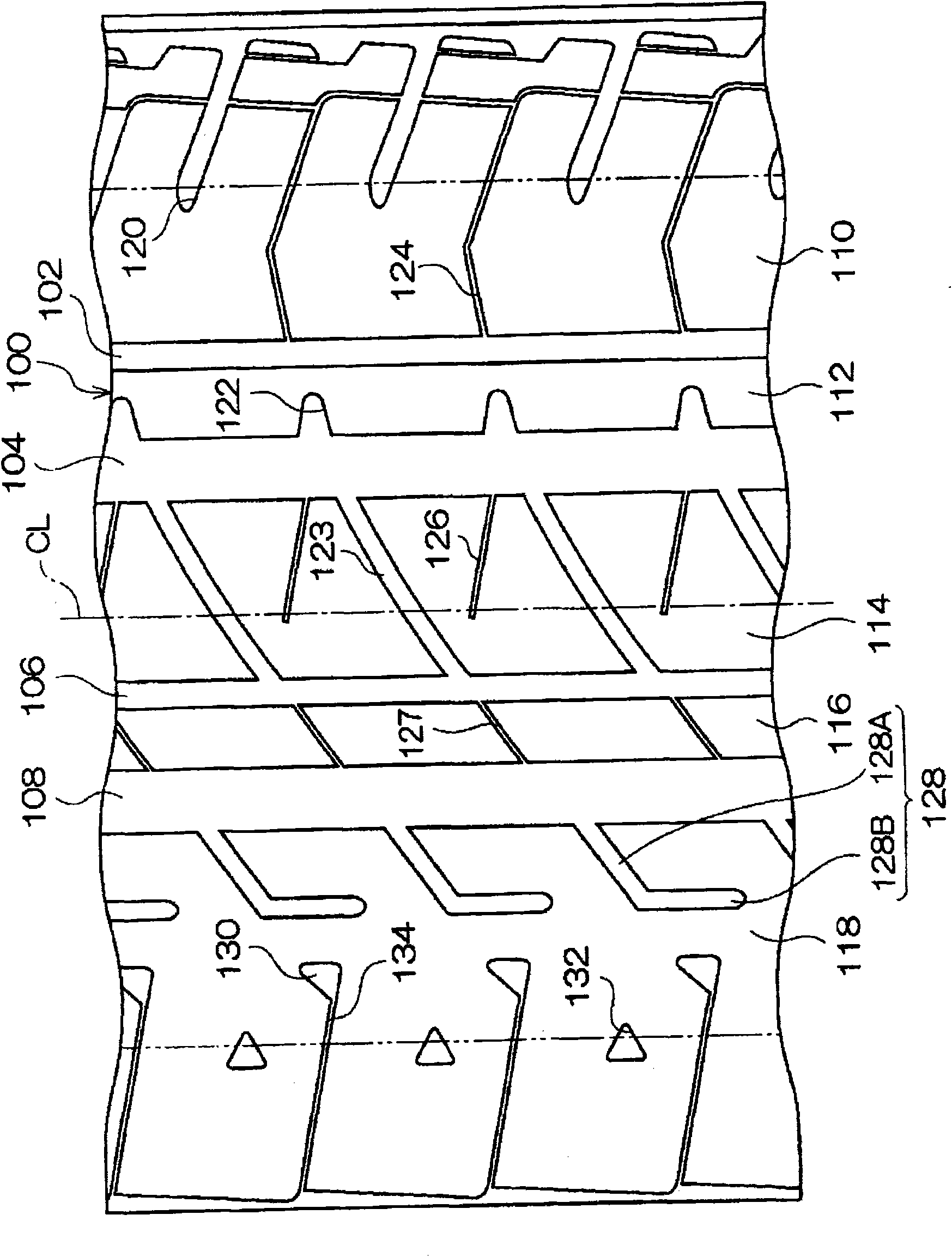

[0082] Previous example: Yes figure 2 Pneumatic tires with the tread pattern shown. In addition, in figure 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com