Foundation pit supporting structure and construction method thereof

A technology for foundation pit support and foundation pit, which is applied in foundation structure engineering, excavation, sheet pile wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached Figure 1-8 The application is described in further detail.

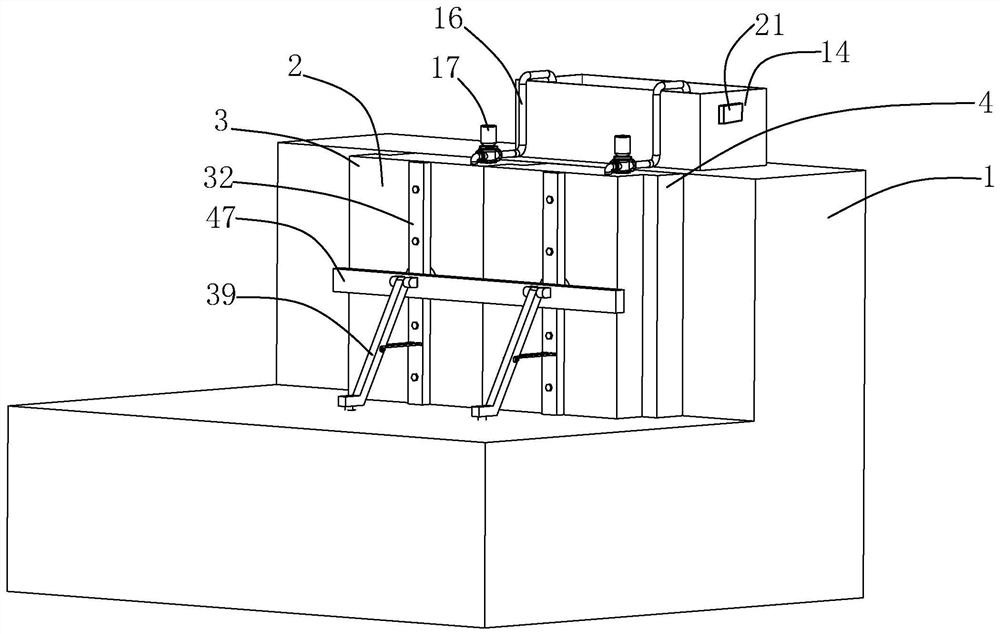

[0044] The embodiment of the application discloses a foundation pit supporting structure and a construction method thereof. refer to figure 1 , a support structure for a foundation pit 1, including a foundation pit 1 and a plurality of protective plates 2 spliced with each other. A first splicing block 3 and a second splicing block 4 are respectively integrally formed at opposite ends of two adjacent protective plates 2 , and both the first splicing block 3 and the second splicing block 4 are arranged along the length direction of the protective plate 2 . The first splicing block 3 is spliced and matched with the second splicing block 4, so as to facilitate the positioning and installation of the protective plate 2.

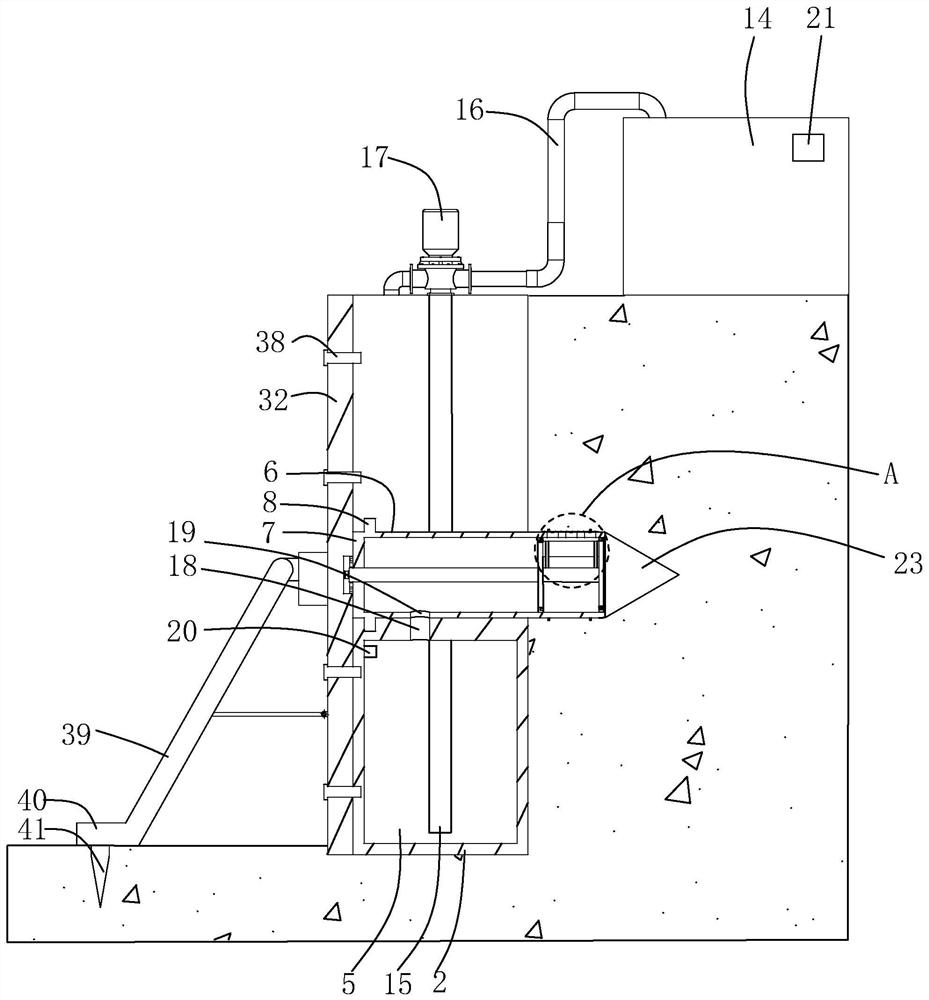

[0045] refer to figure 2 The side surface of the protective plate 2 attached to the side wall of the foundation pit 1 is provided with a through-groove 6 arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com