Foam drainage agent with high temperature resistance, high condensate oil resistance and hypersalinity resistance and preparation method

A foam drainage agent and high salinity technology, which is applied in the fields of high salinity resistance foam drainage agent, high condensate resistance, and new high temperature resistance for natural gas wells, achieving the effect of simple operation and low equipment and environmental requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

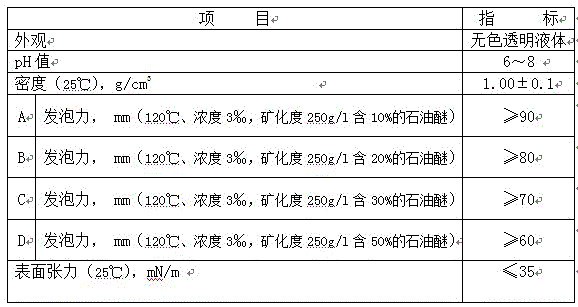

Image

Examples

Embodiment 1

[0016] In this example, we prepared the foam drainage agent with the following weight components by the following method: at room temperature, 60ml cocamidopropyl hydroxysultaine, 20ml cocamidopropyl betaine, 10ml coconut oil Amidopropyl amine oxide and 10ml of water are stirred in a high-speed mixer for 30 minutes and maintained at room temperature for 24 hours.

Embodiment 2

[0018] In this example, we prepared the foam drainage agent with the following weight components by the following method: at room temperature, 50ml cocamidopropyl hydroxysultaine, 25ml cocamidopropyl betaine, 15ml coconut oil Amidopropyl amine oxide and 10ml of water are stirred in a high-speed mixer for 30 minutes, and maintained at room temperature for 24 hours.

Embodiment 3

[0020] In this example, we prepared the foam drainage agent with the following weight components by the following method: At room temperature, 45ml cocamidopropyl hydroxysultaine, 30ml cocamidopropyl betaine, 20ml coconut oil Amidopropyl amine oxide and 5ml of water were stirred in a high-speed mixer for 30 minutes, and maintained at room temperature for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com