Special foam drainage method for low-gas-yield water-flooded well, foam drainage agent and foam drainage device

A water-flooded well and foam-draining agent technology, applied in chemical instruments and methods, earth-moving drilling, wellbore/well components, etc., can solve problems such as foam generation and inability to use bubble-draining technology, and achieve the effect of efficient use of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

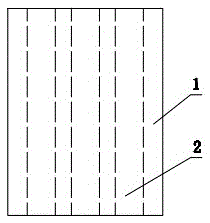

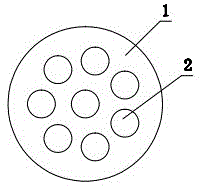

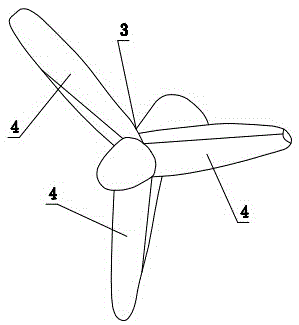

[0043] See attached Figures 1 to 8 , the special bubble discharge method for low-gas production water-flooded wells in the figure uses chemical and / or physical methods to stir the accumulated liquid in low-production gas water-flooded wells to generate fluctuations. The agent mixes with the gas and water in the effusion to generate foam, so as to realize the foam drainage and gas recovery of the low gas production water flooded well;

[0044] The chemical method is to add a foaming agent containing citric acid, sodium bicarbonate, ammonium chloride, and sodium nitrite. The carbon dioxide and nitrogen generated after the foaming agent is dissolved in water are used to treat the liquid accumulation in the low-production gas flooded well. Stirring produces fluctuations;

[0045] The physical method is to install a bubble discharge device in the low-production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com