Integrated and combined gas production method based on plunger gas lifting and foam drainage

A technology of foam drainage and plunger, which is applied in the direction of chemical instruments and methods, drilling compositions, mining fluids, etc., can solve the problems of single process and cumbersome drainage and gas recovery process, and achieve simple and safe operation, wide application range, Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

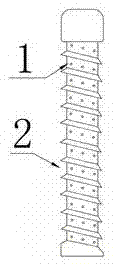

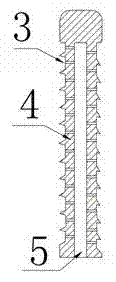

[0014] Such as figure 1 , figure 2 As shown, the present invention is an integrated composite gas recovery method of plunger air lift and foam drainage. First, foam row rods are made according to the diameter of the gas production well, and the foam row rods are used as plungers. The shape of the plunger main body 4 is a cylinder. There is a plunger main cavity 5 inside, and the fluid through holes 1 are evenly distributed outside the plunger main body 4. The plunger main cavity 5 is connected to the fluid through hole 1 through a small fluid channel 3, and the plunger main cavity 5 is connected to the fluid through hole. 1 is designed to increase the downward speed of the plunger. The outer surface of the plunger body 4 is equidistantly distributed with helical trapezoidal grooves 2. The fluid flows in the groove in a spiral trajectory to make the plunger rotate and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com