Foaming drainage agent, preparation method and application

A foam drainage agent and fat technology, which is applied in chemical instruments and methods, earthwork drilling, mining fluids, etc., can solve the problem that the effect of the foam drainage agent cannot meet more and more severe field requirements, and achieves good promotion and application prospects. Economic benefits, balanced development effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

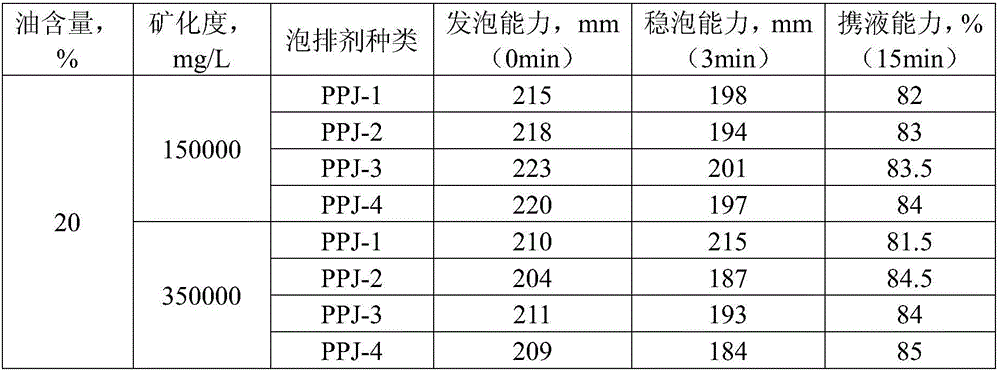

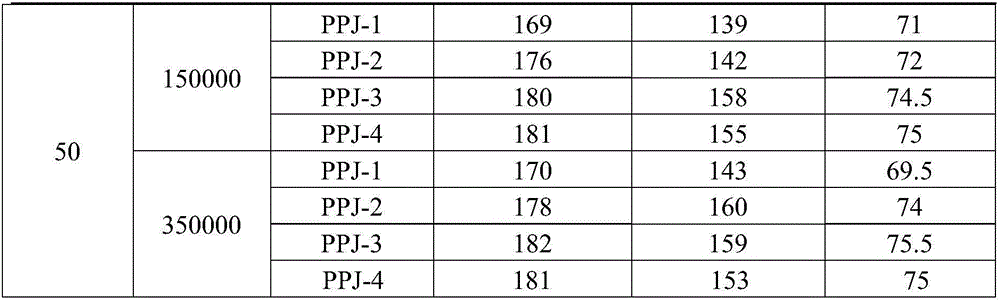

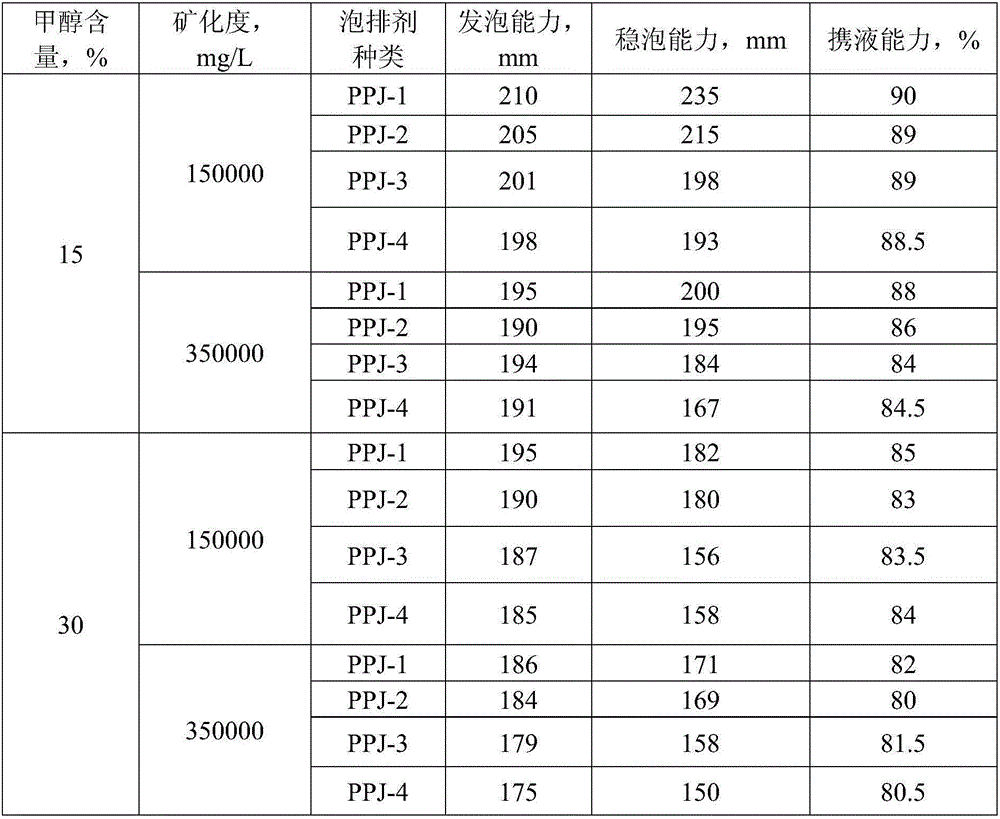

Examples

Embodiment 1

[0024] This embodiment provides a foam drainage agent (code name PPJ-1), which is formulated by the following components in mass percentage: 30% betaine, 30% amine oxide, 15% fatty alcohol polyoxyethylene ether sulfate, alkane Glycoside 4%, water 21%.

[0025] In this embodiment, betaine is cocamidopropyl betaine, amine oxide is lauryl amidopropyl amine oxide, fatty alcohol polyoxyethylene ether sulfate is fatty alcohol polyoxyethylene ether sodium sulfate, and the alkyl carbon in the alkyl glycoside is For C8-C10.

[0026] making process:

[0027] Step 1) Measure the water, betaine, amine oxide, fatty alcohol polyoxyethylene ether sulfate and alkyl glycoside of formula quantity;

[0028] Step 2) Dissolving fatty alcohol polyoxyethylene ether sulfate in water, adding betaine while stirring, and then adding amine oxide, stirring evenly, adding alkyl glucoside, stirring well to obtain the product.

Embodiment 2

[0030] This embodiment provides a foam drainage agent (code name PPJ-2), which is formulated by the following components in mass percentage: 15% betaine, 45% amine oxide, 10% fatty alcohol polyoxyethylene ether sulfate, alkane Glycoside 2%, water 28%.

[0031] The betaine in this example is lauryl sultaine, the amine oxide is lauryl amidopropyl amine oxide, the fatty alcohol polyoxyethylene ether sulfate is fatty alcohol polyoxyethylene ether potassium sulfate, and the alkyl glycosides The base carbon is C12-C14. The preparation process refers to Example 1.

Embodiment 3

[0033] This embodiment provides a foam drainage agent (code name PPJ-3), which is formulated by the following components in mass percentage: 28% betaine, 42% amine oxide, 12% fatty alcohol polyoxyethylene ether sulfate, alkane Glycoside 1%, water 17%.

[0034] The betaine in this example is lauryl amidopropyl betaine, the amine oxide is lauryl dimethyl amine oxide, the fatty alcohol polyoxyethylene ether sulfate is fatty alcohol polyoxyethylene ether sodium sulfate, and the alkyl glycoside The middle alkyl carbon is C12-C14. The preparation process refers to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com