Foam drainage agent resistant to gas condensate and mineralization degree and preparation method thereof

A foam drainage agent, anti-condensation oil technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of reducing the foaming and stabilizing foam of the foam drainage agent, and the liquid carrying capacity of the foam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Preparation of foaming agent

[0020] The dosage of each raw material component in the foam drainage agent of this embodiment is as follows:

[0021] AES: 18%; saponin: 2%; betaine: 6%; polyacrylamide (molecular weight: 10 million): 0.04%; the balance is water.

[0022] The foam drainage agent of this embodiment is synthesized through the following steps:

[0023] (1) Add 50% of the total amount of water to the reactor, heat to 40°C, add polyacrylamide, stir for 0.5 to 1 hour, then add the remaining 50% water, and stir until uniform;

[0024] (2) Add fatty alcohol polyoxyethylene ether sodium sulfate, betaine, and saponins into the reaction kettle, and stir thoroughly for 1 to 2 hours; obtain a foam drainage agent (AZT-P) suitable for natural gas exploitation.

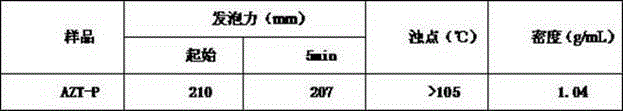

[0025] The properties of the prepared foaming agent are shown in Table 2.

Embodiment 2

[0027] Performance test of foaming agent

[0028] Laboratory preparation of mineralized water with 60g / L salinity: Weigh 10g of anhydrous calcium chloride (CaCl2) and 50g of sodium chloride (NaCl) in a beaker, dissolve and dilute with distilled water to a total volume of 1L. The total salinity is 60g / L (all reagents used are chemically pure).

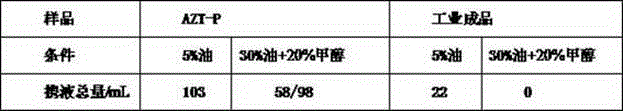

[0029] Pipette 4mL finished product to prepare 1000mL test solution, and determine its carrying capacity:

[0030] (1) 5% oil (volume fraction): the liquid carrying capacity is 103mL;

[0031] (2) 30% oil + 20% methanol (volume fraction): the total amount of liquid carried is 98 mL (of which water and methanol are 58 mL).

[0032] Reference ratio 1

[0033] Pipette 4mL of industrial products to prepare 1000mL test solution (its salinity is 60g / L, containing 10g of anhydrous calcium chloride (CaCl2) and 50g of sodium chloride (NaCl)), and determine its carrying capacity:

[0034] (1) 5% oil (volume fraction): the liquid carrying capacity is 22mL;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com