Low-solid-phase and high-temperature-resistant foam drilling fluid and preparation method thereof

A technology of high temperature resistance and drilling fluid, which is applied in the field of oil field drilling fluid, can solve the problems of poor stability of foam drilling fluid, insufficient rock carrying capacity, and failure to meet the performance requirements of foam drilling fluid, etc., and achieve good foam stability and large adjustable range , the effect of reducing filtration loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

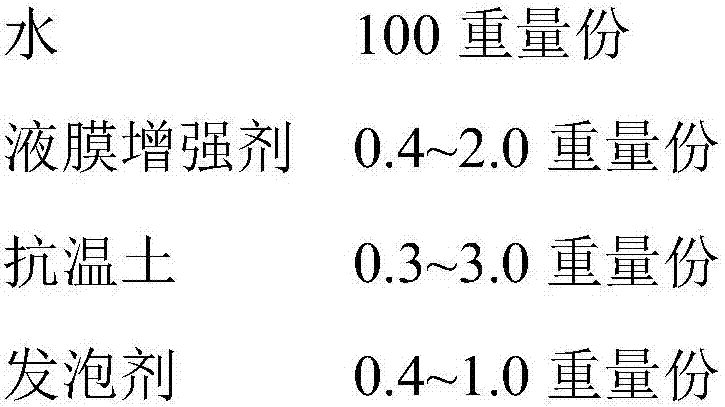

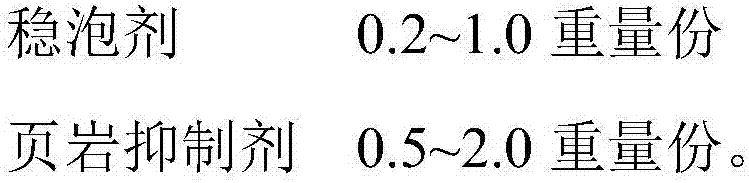

[0031] This embodiment provides a low-solid-phase high-temperature-resistant foam drilling fluid, which includes the following components:

[0032] 0.3 parts by weight of liquid film enhancer, 0.5 parts by weight of anti-temperature soil, 0.6 parts by weight of foaming agent, 0.6 parts by weight of foam stabilizer, 0.8 parts by weight of shale inhibitor, and 100 parts by weight of water.

[0033] The low-solid-phase high-temperature-resistant foam drilling fluid of this embodiment is prepared by the following method:

[0034] Preparation of base liquid: add 100 parts by weight of water to a high stirring cup at room temperature, slowly add 0.3 parts by weight of dodecyltrimethylammonium chloride, stir for 5 to 25 minutes to obtain a uniform solution, and continue to add 0.5 parts by weight of calcium After stirring for 3 hours, add 0.6 parts by weight of C12 alkyl ether, 0.6 parts by weight of sulfopolyacrylamide and 0.8 parts by weight of C10 alkyl-terminated amine polyether,...

Embodiment 2

[0040] This embodiment provides a low-solid-phase high-temperature-resistant foam drilling fluid, which includes the following components:

[0041] 0.5 parts by weight of liquid film strengthening agent, 0.5 parts by weight of anti-temperature soil, 0.5 parts by weight of foaming agent, 0.5 parts by weight of foam stabilizer, 1.0 parts by weight of shale inhibitor, and 100 parts by weight of water.

[0042] The low-solid-phase high-temperature-resistant foam drilling fluid of this embodiment is prepared by the following method:

[0043] Preparation of base liquid: add 100 parts by weight of water to a high stirring cup at room temperature, slowly add 0.5 parts by weight of dodecyltrimethylammonium bromide, stir for 5 to 25 minutes to obtain a uniform solution, and continue to add 0.5 parts by weight of concave-convex Stick powder, after stirring for 3 hours, add 0.5 parts by weight of C14 alkylammonium, 0.5 parts by weight of polyacrylamide and 1.0 parts by weight of polyethyl...

Embodiment 3

[0049] This embodiment provides a low-solid-phase high-temperature-resistant foam drilling fluid, which includes the following components:

[0050] 0.5 parts by weight of liquid film enhancer, 0.5 parts by weight of anti-temperature soil, 0.6 parts by weight of foaming agent, 0.6 parts by weight of foam stabilizer, 0.8 parts by weight of shale inhibitor, and 100 parts by weight of water.

[0051] The low-solid-phase high-temperature-resistant foam drilling fluid of this embodiment is prepared by the following method:

[0052] Preparation of base liquid: add 100 parts by weight of water to a high stirring cup at room temperature, slowly add 0.5 parts by weight of dodecyltrimethylammonium chloride, stir for 5 to 25 minutes to obtain a uniform solution, continue to add 0.5 parts by weight of Mongolian Destonening, after stirring for 3 hours, add 0.6 parts by weight of C12 alkylammonium, 0.6 parts by weight of polyacrylamide and 0.8 parts by weight of ethylene glycol, and stir for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface contact angle | aaaaa | aaaaa |

| Surface contact angle | aaaaa | aaaaa |

| Surface contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com