Sealing monitoring method for simulating sealing conditions of transformer bushing

A technology for simulating transformers and airtightness, which is applied in the field of power systems, can solve the problems of adjustment control, airtightness monitoring and test workload, difficult internal temperature and other problems, achieve multiple meter interfaces, prevent bushing failures, and reduce device size small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

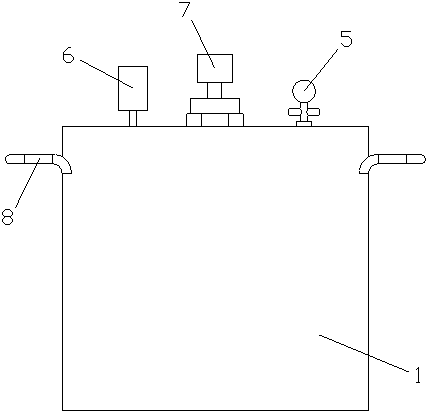

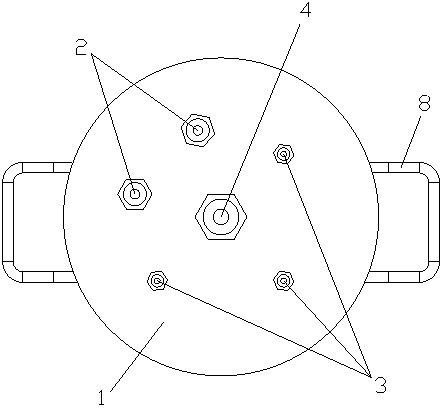

[0025] Such as Figure 1~2 As shown, a sealing monitoring method for simulating the sealing condition of the transformer bushing comprises the following steps:

[0026] (1) Provide a device for simulating the sealing condition of the transformer bushing, the device is a cylindrical container 1, and the top surface of the cylindrical container 1 is provided with six threaded connections, and the six threaded connections include two external threaded connections 2 and four female threaded interfaces, the two external threaded interfaces 2 are used as oil filling ports;

[0027] (2) Fill the transformer oil into the cylindrical container 1 from the two oil filling ports until it is almost full, that is, there is some space on the top of the cylindrical container 1, and then seal the oil filling port with a sealing ring and nut to ensure the tightness reliable;

[0028] (3) Connect two SF with three-way valves through the adapter 6 The gas density meter 5 is respectively instal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com