Template with rigid-flexible composite structure and partition wall construction method by retaining roadway along goaf thereof

A structural formwork and rigid-flexible composite technology, which is applied in the direction of formwork/formwork/working frame, formwork/formwork components, earthwork drilling and mining, etc., can solve the problems of high construction cost, poor airtightness, and slow construction speed, and achieve Improved bearing capacity and anti-deformation capacity, improved stability, and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

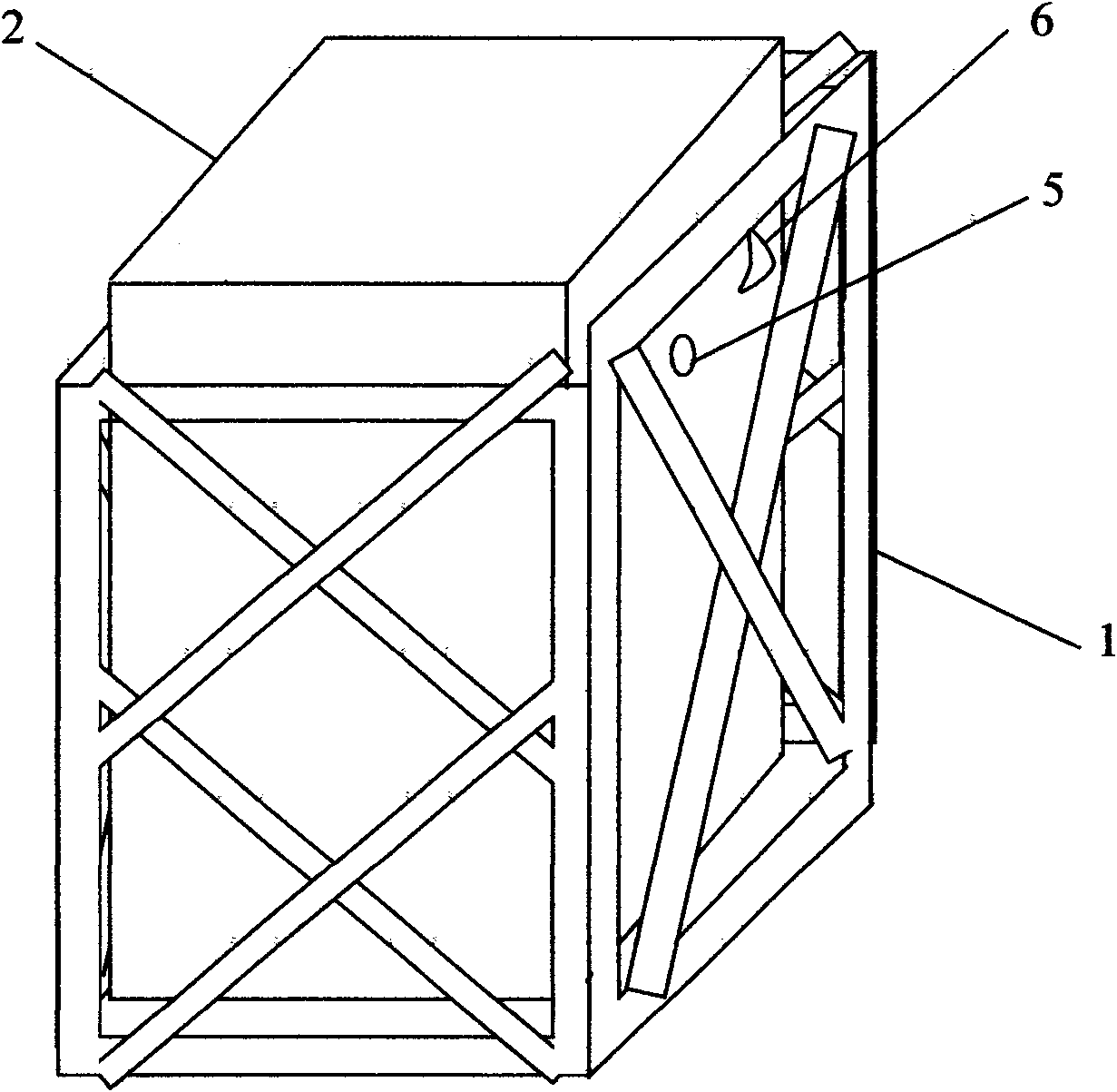

[0033] Such as figure 1 The rigid-flexible composite structure formwork shown is composed of two parts: the rigid outer formwork 1 of the outer layer and the flexible inner tire mold 2 arranged in the rigid outer formwork 1 .

[0034] The flexible inner tire mold 2 is a closed bag structure with an openable opening made of fiber cloth, and is provided with a grouting port 5 and a suspension buckle 6 .

[0035] The method of using the rigid-flexible composite structure template for concrete structure construction is carried out according to the following steps:

[0036] 1) fixing the flexible inner tube mold 2 on the top plate;

[0037] 2) fixing the rigid outer template 1;

[0038] 3) Connect the concrete pump to the grouting port 5;

[0039] 4) Pumping concrete;

[0040] 5) Remove the rigid outer template 1 after pumping for 3 hours.

Embodiment 2

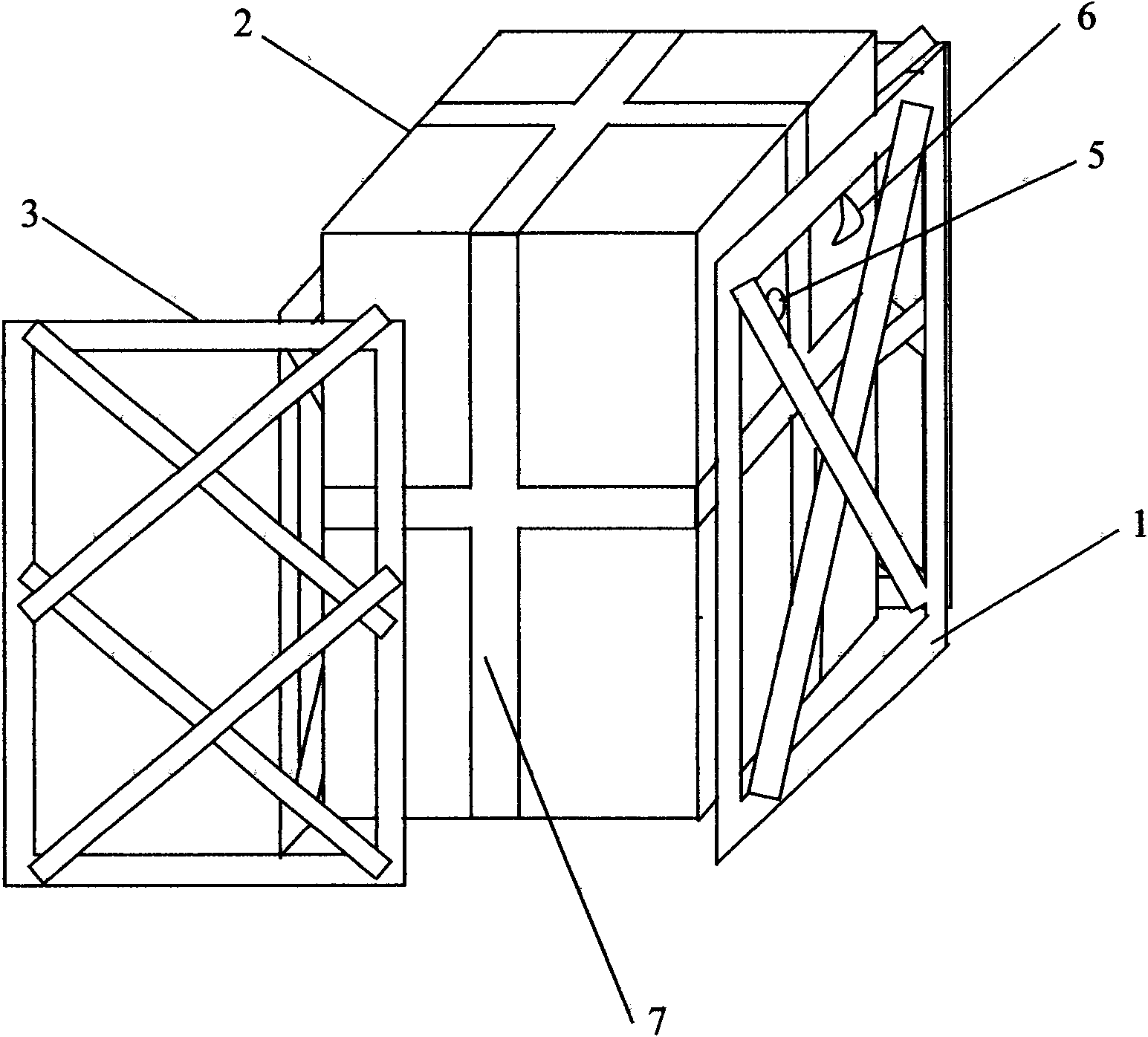

[0042] Such as figure 2 The rigid-flexible composite structure formwork shown is composed of two parts: the rigid outer formwork 1 of the outer layer and the flexible inner tire mold 2 arranged in the rigid outer formwork 1 . One side of the rigid outer template 1 is a slidable and fixed baffle plate 3 .

[0043] The flexible inner tube mold 2 is a closed bag structure, and the flexible inner tube mold 2 is a fiber cloth bag.

[0044] The flexible inner tire mold 2 is provided with an elastically deformable strip 7 adapted to the rigid outer template and the expansion top.

[0045] The method of using the rigid-flexible composite structure template for concrete structure construction is carried out according to the following steps:

[0046] 1) Fix the flexible inner tube mold 2 on the rigid outer template 1;

[0047] 2) Fix the baffle plate 3 of the rigid outer template 1;

[0048] 3) Connect the concrete pump to the grouting port 5;

[0049] 4) Pumping concrete;

[005...

Embodiment 3

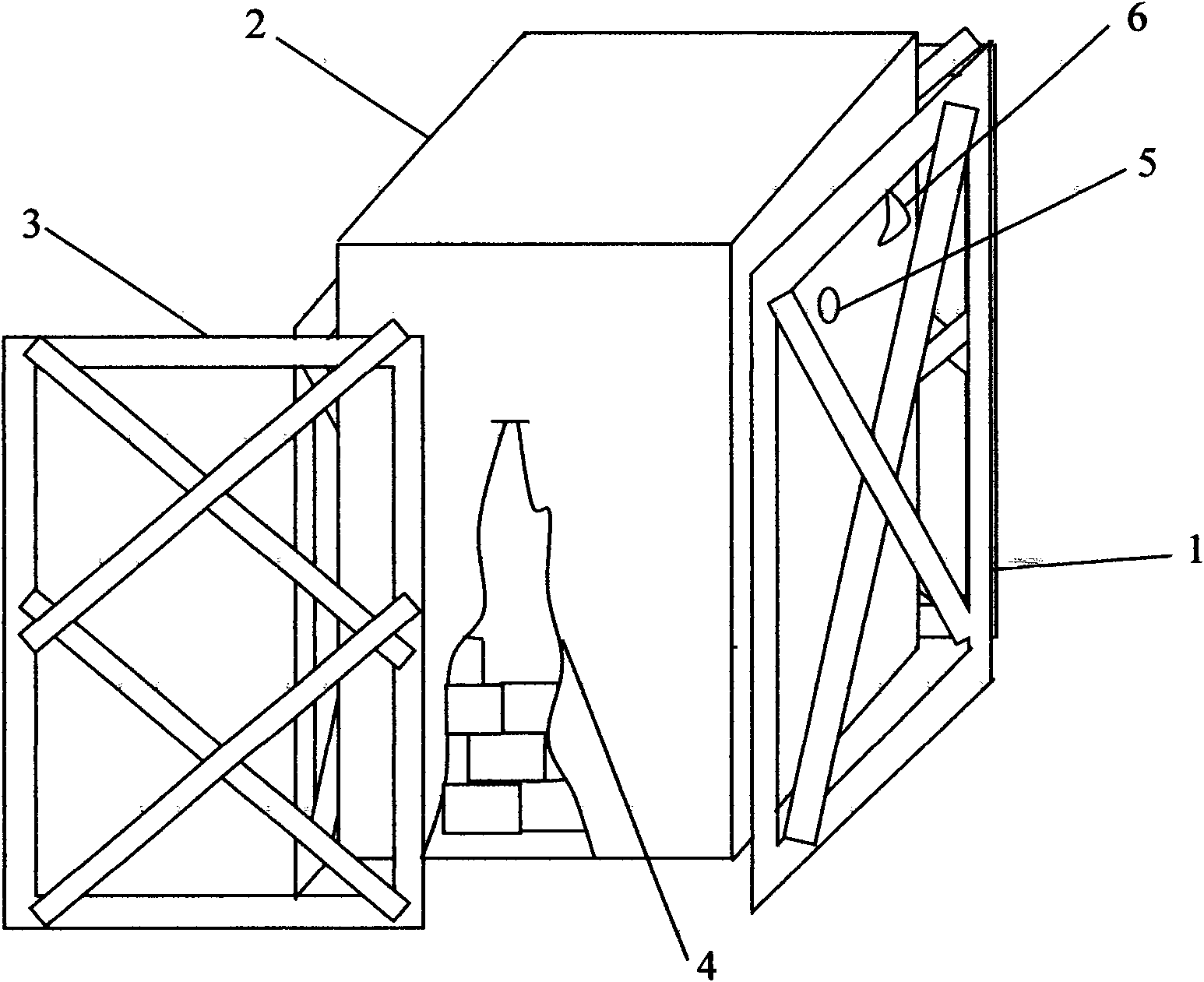

[0052] Such as image 3 The rigid-flexible composite structure formwork shown is composed of two parts: the rigid outer formwork 1 of the outer layer and the flexible inner tire mold 2 arranged in the rigid outer formwork 1 .

[0053] The flexible inner tire mold 2 is a closed bag structure with an openable opening 4, and is provided with a grouting port 5 and a suspension buckle 6. The openable opening length is between 100mm-3000mm.

[0054] The method for carrying out grouting masonry structure construction by using rigid-flexible composite structure formwork is characterized in that it is carried out according to the following steps:

[0055] 1) Fix the flexible inner tube mold 2 on the top plate or on the rigid outer template 1;

[0056] 2) Open the inner tube mold to open the opening 4, put in blocks, bricks, gravel or gangue; close the pocket;

[0057] 3) Fixing the rigid outer formwork 1;

[0058] 4) Connect the grouting pipe to the grouting port 5 and grout;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com