Injection apparatus for resin transfer moulding technology

A technology of resin transfer molding and injection equipment, which is applied in the field of injection equipment, can solve problems such as impossibility, complex control system, and complex equipment, and achieve the effects of improving product quality, wide adaptability, and simplifying equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

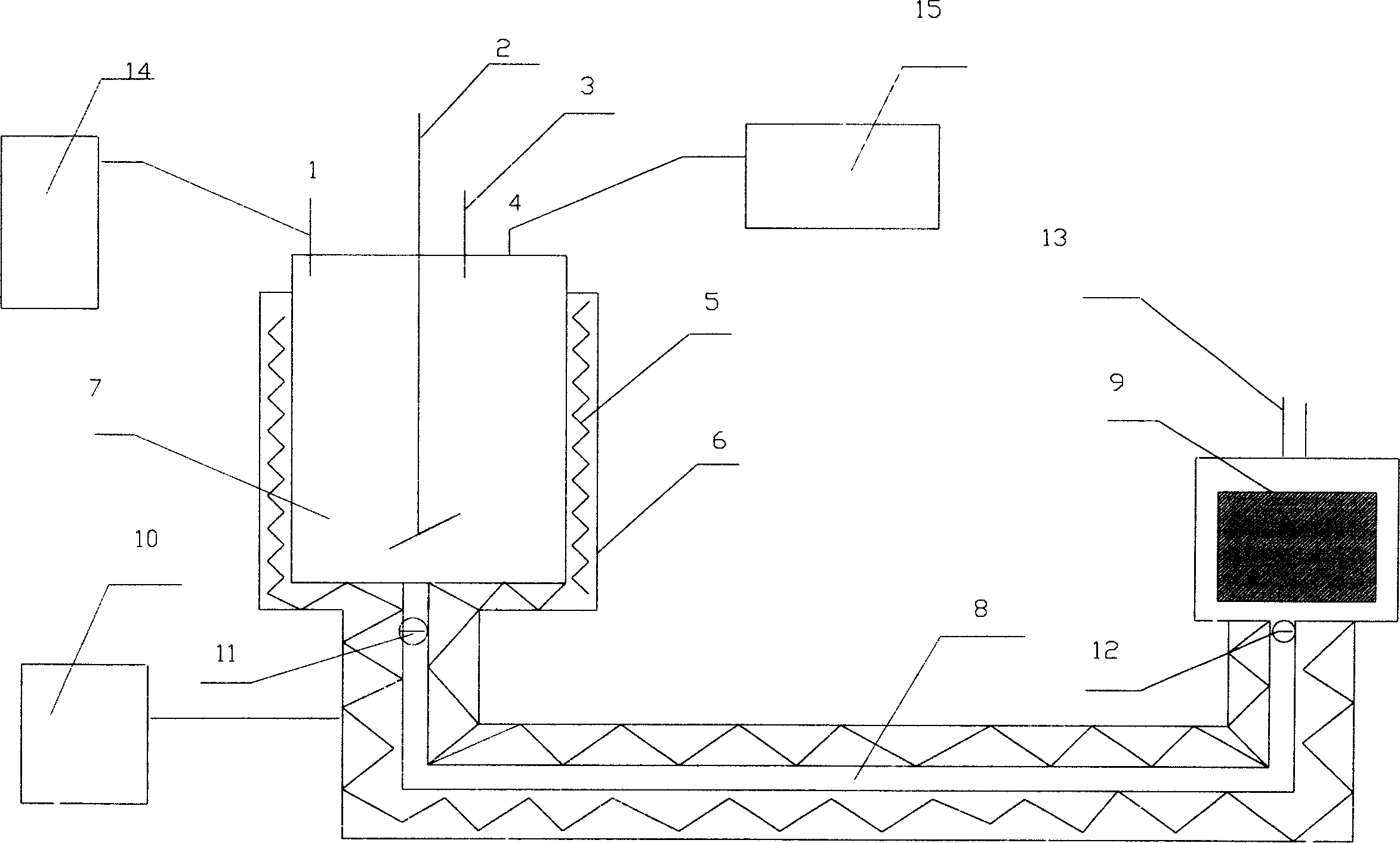

Method used

Image

Examples

Embodiment 1

[0023] Prepare rectangular composite specimens.

[0024] First fiber prefabricated part is packed in the mold 9, and this mold cavity is consistent with final product; After the ratio of epoxy resin TDE-85 and 2-methylimidazole curing agent 100: 1 is mixed uniformly, from described Fill the injection port 3 into the resin tank 7, vacuumize the interface 4, remove the air bubbles in the resin, set the temperature of the oil bath heating system 6 to 40°C according to the viscosity-temperature characteristics of the resin, and heat the oil bath In the working state; when the temperature reaches the set value of 40°C, set the required pressure of 0.2Mpa according to the fiber volume content and structure of the prefabricated part, and open the output switch 11 connected between the resin tank 7 and the delivery pipeline 8 at the same time The input switch 12 communicated with the delivery pipeline 8 and the mold 9, and the air source 14 is connected at the air nozzle 1, so that th...

Embodiment 2

[0026] Fabrication of three-dimensional structural composite joints

[0027]The fiber preform of the splice is first loaded into a mold 9 whose cavity corresponds to the final splice article. Pour the modified phenolic resin into the resin tank 7 from the injection port 3, vacuumize the interface 4, get rid of the bubbles of the resin in the resin tank 7, set the temperature of the oil bath heating system 6 according to the viscosity-temperature characteristics of the resin The temperature is 90°C, so that the oil bath heating system 6 is in working condition. When the temperature reaches the set value of 90° C., set the required pressure of 0.6 Mpa according to the fiber volume content and structure of the preform, and the remainder is the same as in Example 1. The three-dimensional structural composite material joint made by the injection device of the present invention is as follows: image 3 shown. Compared with the traditional injection equipment, the injection equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com