Single-component thread locking epoxy precoated adhesive and preparation method thereof

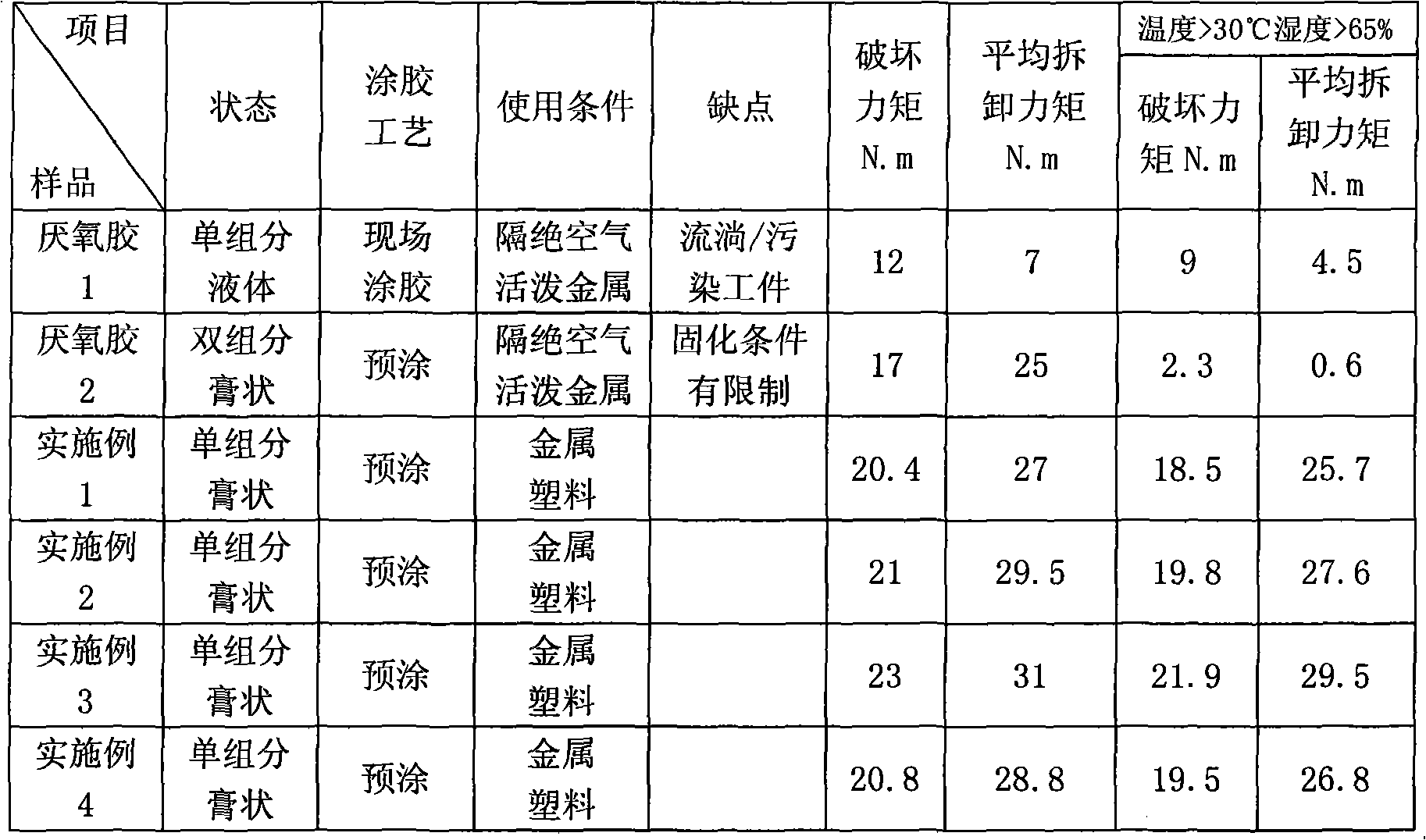

A locking ring, single-component technology, applied in the direction of epoxy resin glue, chemical instruments and methods, novolac epoxy resin adhesive, etc., can solve the problem of low efficiency of thread locking glue, harsh curing conditions, pollution Workpieces and other problems, to achieve the effect of less restrictions on curing conditions, good locking performance, high breaking torque and average disassembly torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, at first, add gum arabic 3g and distilled water 15g in the 500ml there-necked flask that is equipped with stirrer, stir and be warming up to 50 ℃, after gum arabic dissolves completely, add bisphenol A type epoxy resin (E- 44) 40g and active diluent butyl glycidyl ether 10g, increase the speed to 2000rpm, disperse the solution into 50-200μm droplets, cool down to 40-50℃, slowly add 5g of pre-mixed urea, A mixed solution of 7 g of resorcinol, 20 g of 37% formaldehyde solution, and 25 g of distilled water, 10 minutes after the addition, add 15 g of 10% hydrochloric acid solution, keep the temperature, continue stirring for 8 h, and adjust the temperature of the system with 10% sodium hydroxide solution. When the pH value reaches 4-5, continue to stir for 30 minutes, stop heating and stirring, let stand for 30 minutes, remove the floating matter above, rinse 5 times with distilled water, vacuum filter, and dry to obtain epoxy resin capsules;

[0032] Add 2g o...

Embodiment 2

[0034] Embodiment 2, first add gum arabic 9g and distilled water 30g in the there-necked flask of 500ml that is equipped with stirrer, stir and be warming up to 85 ℃, after gum arabic dissolves completely, add bisphenol A type epoxy resin (E-44 ) 70g and active diluent butyl glycidyl ether 80g, increase the rotation speed to 2000rpm, disperse the solution into 50-200μm droplets, cool down to 40-50℃, slowly add 13g of pre-mixed urea, A mixed solution of 21g of hydroquinone, 38g of 37% formaldehyde solution, and 70g of distilled water, 10 minutes after the addition, add 10% hydrochloric acid solution to adjust the pH to 2-3, keep this temperature, continue to stir for 8 hours, and use 10% sodium hydroxide The solution adjusted the pH value of the system to 4-5, continued to stir for 30 minutes, stopped heating and stirring, stood for 30 minutes, removed the floating matter above, rinsed 5 times with distilled water, vacuum filtered, and dried to obtain epoxy resin capsules;

[0...

Embodiment 3

[0037] Embodiment 3, first add gum arabic 7g and distilled water 22g in the there-necked flask of 500ml that is equipped with stirrer, stir and be warming up to 60 ℃, after gum arabic dissolves completely, add bisphenol A type epoxy resin (E-44 ) 55g and active diluent butyl glycidyl ether 45g, increase the speed to 2000rpm, disperse the solution into 50-200μm droplets, cool down to 40-50℃, slowly add 10g of pre-mixed urea, A mixed solution of quinone 15g, 37% formaldehyde solution 29g, distilled water 45g, 10min after adding, add 10% hydrochloric acid solution to adjust the pH to 2-3, keep this temperature, continue to stir for 8h, use 10% sodium hydroxide The solution adjusted the pH value of the system to 4-5, continued to stir for 30 minutes, stopped heating and stirring, stood for 30 minutes, removed the floating matter above, rinsed 5 times with distilled water, vacuum filtered, and dried to obtain epoxy resin capsules;

[0038] Then add 3 g of gum arabic and 18 g of dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com