Two-dimensional thin film material coated on microsphere surfaces and simple method for stripping two-dimensional thin film material

A technology of two-dimensional materials and thin-layer materials, which is applied in the preparation of microspheres, chemical instruments and methods, and microcapsule preparations. Synapse, complete crystal structure, good product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] A kind of preparation method of the core-shell structure of graphene-coated aluminum oxide particles provided by the invention comprises the following steps:

[0054] a) graphite balls are put into a beaker filled with dilute hydrochloric acid; the size of graphite balls is between 5mm and 15mm, preferably between 8mm and 10mm, and is processed by high-pressure graphite with a purity of 99.99%. No polishing, no surface treatment; the concentration of hydrochloric acid is between 1:6 and 1:1; ultrasonic cleaning at room temperature, the ultrasonic power is between 30W and 60W, and the cycle is between 10 and 20min. Replace the solution and repeat the above step 3 times to 10 times until the cleaning solution no longer becomes turbid; remove the tiny graphite debris on the surface of the graphite ball to make the surface smooth;

[0055] b) mixing graphite balls and alumina particles in proportion, the mass ratio of graphite balls to alumina is between 1:2 and 2:1, prefer...

Embodiment 1

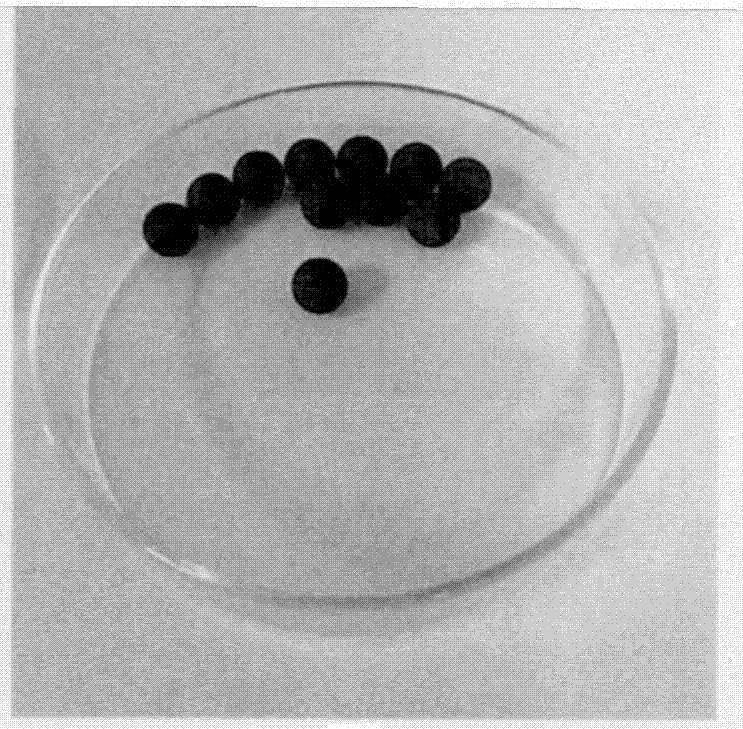

[0063] a) Take ten graphite balls, the diameter of graphite balls is 10mm, and the total mass is 10g; put it into a beaker filled with dilute hydrochloric acid, the concentration of hydrochloric acid is 1:6; ultrasonic cleaning at room temperature, ultrasonic power is 45W, cycle After 15 minutes, replace the solution with a new solution and repeat the above steps 5 times until the cleaning solution no longer becomes turbid; remove the tiny graphite debris on the surface of the graphite ball to make the surface smooth;

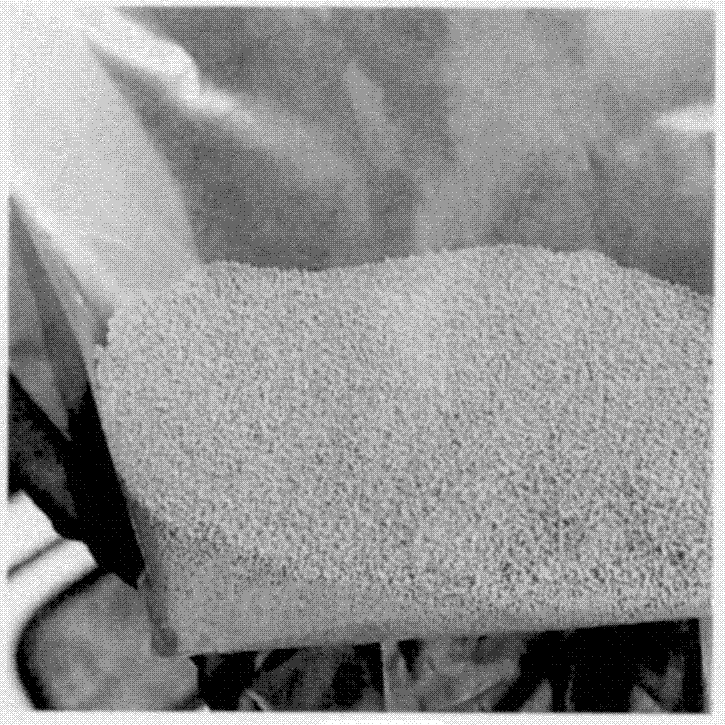

[0064] b) mixing graphite balls and alumina particles in a mass ratio of 1:1, weighing 10 g of alumina particles; the size of the alumina particles is between 200 μm and 300 μm;

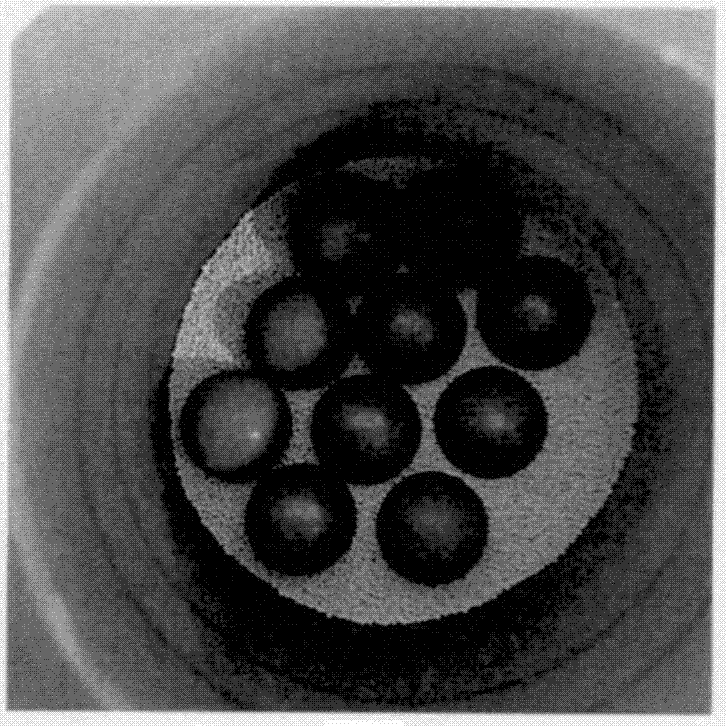

[0065] c) Put mixture A into a 50ml agate ball mill jar, the total volume of graphite balls and alumina is 1 / 4 of the total volume; mix with a ball mill under air atmosphere, the speed is 500rpm, and the time is 2.5h to get mixture B ;

[0066] d) The graphite spheres in the mixture ...

Embodiment 2

[0068] a) take by weighing the aluminum oxide particles uniformly coated with graphene obtained in Example 1, 5g, into a 30ml reagent bottle;

[0069] b) Add 20ml of 1,2-dichloroethane to the reagent bottle, ultrasonic; the ultrasonic power is 45W, and the time is 5 minutes; the graphene on the surface of the alumina particles is all transferred to the solution;

[0070] c) Using a 100-mesh filter screen to separate the alumina particles from the liquid to obtain a graphene dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com