Black soya bean screening machine with cleaning function before fermented soya bean production

A screening machine, black bean technology, applied in the directions of sieving, filtration separation, solid separation, etc., can solve the problems of low efficiency, easy screening errors, troublesome operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

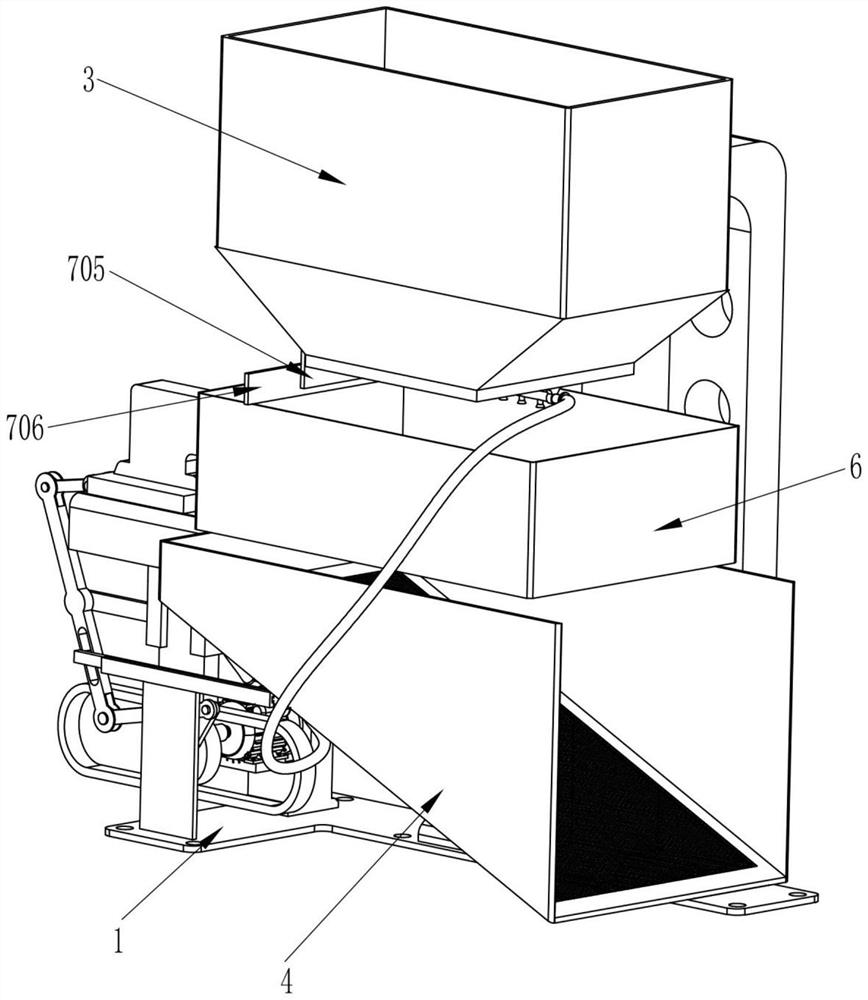

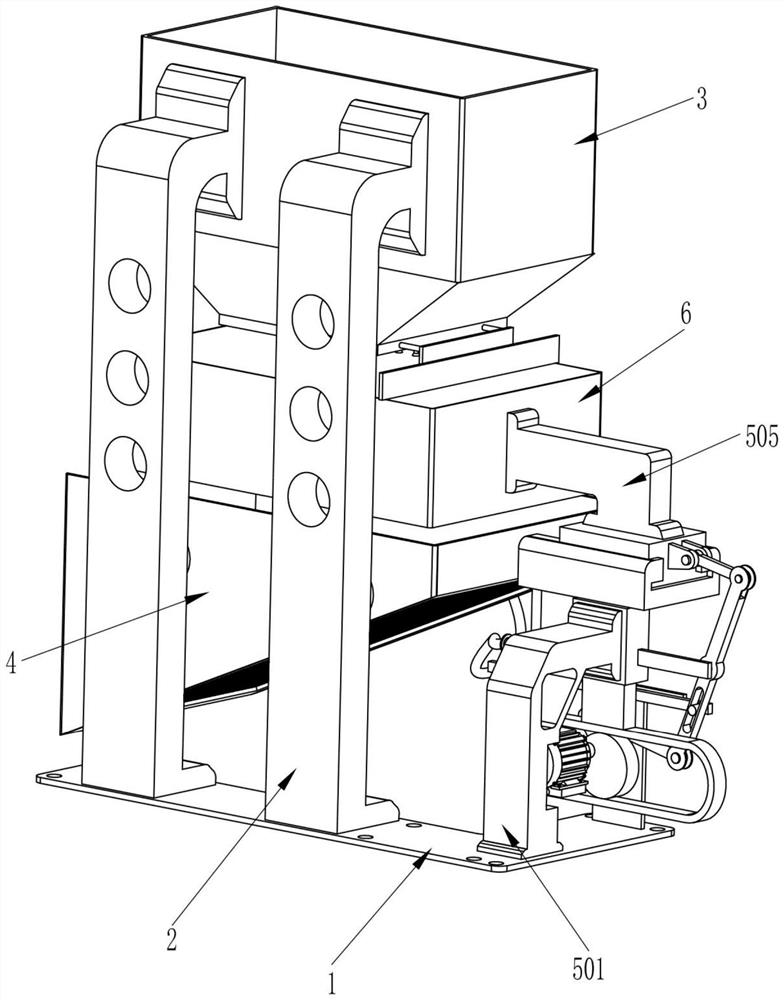

[0022] A kind of black bean screening machine with cleaning function before fermented soybean production, such as Figure 1-6 As shown, it includes an L-shaped plate 1, a fixed seat 2, a material storage frame 3, a material guide frame 4, a screening frame shaking mechanism 5, a screening frame body 6, a black bean intermittent blanking mechanism 7 and a black bean washing mechanism 8, two The fixed seat 2 provided with three circular holes for fixing is fixedly installed on the L-shaped plate 1 and arranged symmetrically, and the storage frame 3 for placing black beans is fixedly installed on the two fixed seats 2, and the The material guide frame 4 that can filter the excess moisture of black beans is fixedly installed on the front side of the two fixed seats 2 and is located below the material storage frame 3. The shaking mechanism 5 of the screening frame is installed on the L-shaped plate 1. The screening frame body 6 capable of screening black beans is installed on the s...

Embodiment 2

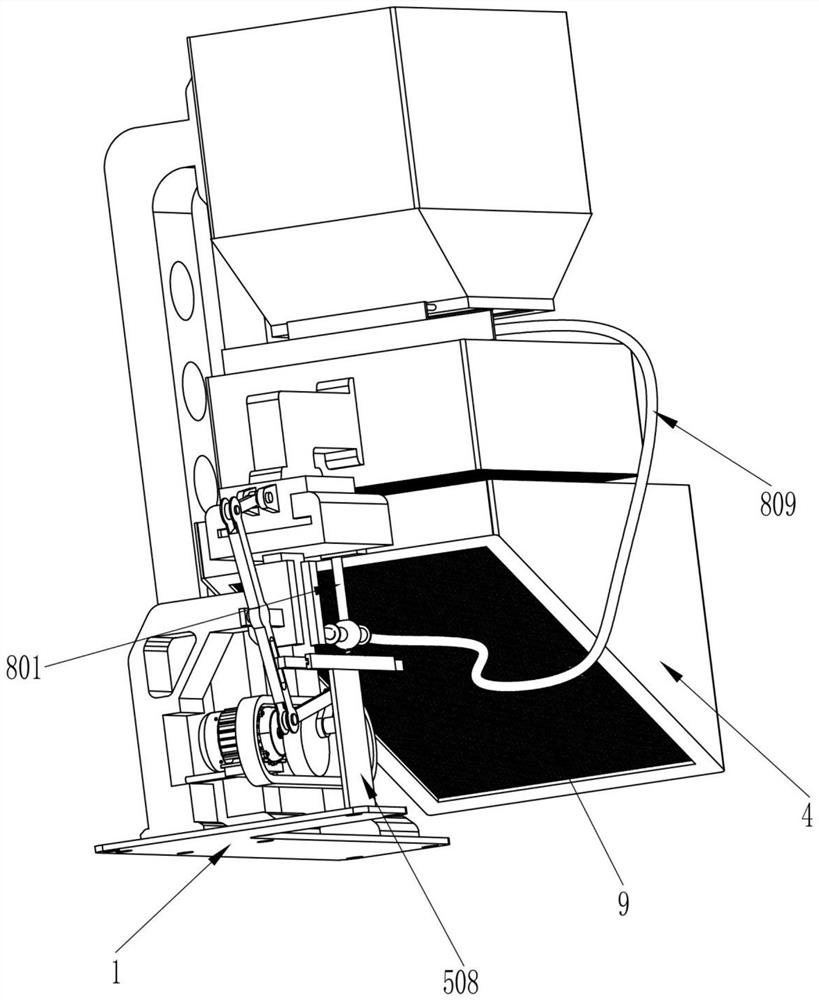

[0026] On the basis of Example 1, such as Figure 1-6 As shown, the black bean flushing mechanism 8 capable of intermittently spraying clean water to clean the black beans includes a mounting seat 801, a circular cavity valve body 802, a spherical liquid retaining column 803, a rotating shaft 804, a torsion spring 805, a sector gear 806, Fixed sleeve 807, liquid spray pipe 808, first hose 809, second hose 8010, slide rail 8011 and sliding rack 8012, the mounting seat 801 which plays a fixed role is fixedly installed on the left side of material guide frame 4 and close to On the sliding seat 504, the circular cavity valve body 802 is fixedly installed on the lower end of the mounting seat 801, and the spherical liquid retaining column 803 which acts as a switch is set in the circular cavity valve body 802 and the middle part of the spherical liquid retaining column 803 is opened. The upper end of the connecting shaft 804 passes through the circular cavity valve body 802 and is ...

specific Embodiment approach

[0028] Specific implementation method: when black beans need to be screened and cleaned before fermented soya bean production, first manually pour black beans of different sizes into the material storage frame 3, place a collection box at the outlet of the right end of the material guide frame 4, and then open The servo motor 506 rotates counterclockwise, driving the transmission shaft 507 to rotate counterclockwise, thereby driving the first connecting rod 509 and the disk 5015 to rotate counterclockwise, and under the joint action of the disk 5015 and the sliding plate 503, the sliding seat 504 and the slider 5014 reciprocatingly moves up and down, and at the same time, under the joint action of the second connecting rod 5010, the swing groove rod 5012 and the connecting rod 5013, the slider 5014 moves up and down while reciprocatingly sliding left and right, and drives the screening frame body 6 through the connecting seat 505 Reciprocating up and down and shaking left and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com