Grading type screening plant used for screening haycite

A screening device and a graded technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of low work efficiency, easy blockage of screen holes, time-consuming and labor-intensive problems, and achieve good practicability, reduce dust, prevent sieving The effect of pore clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

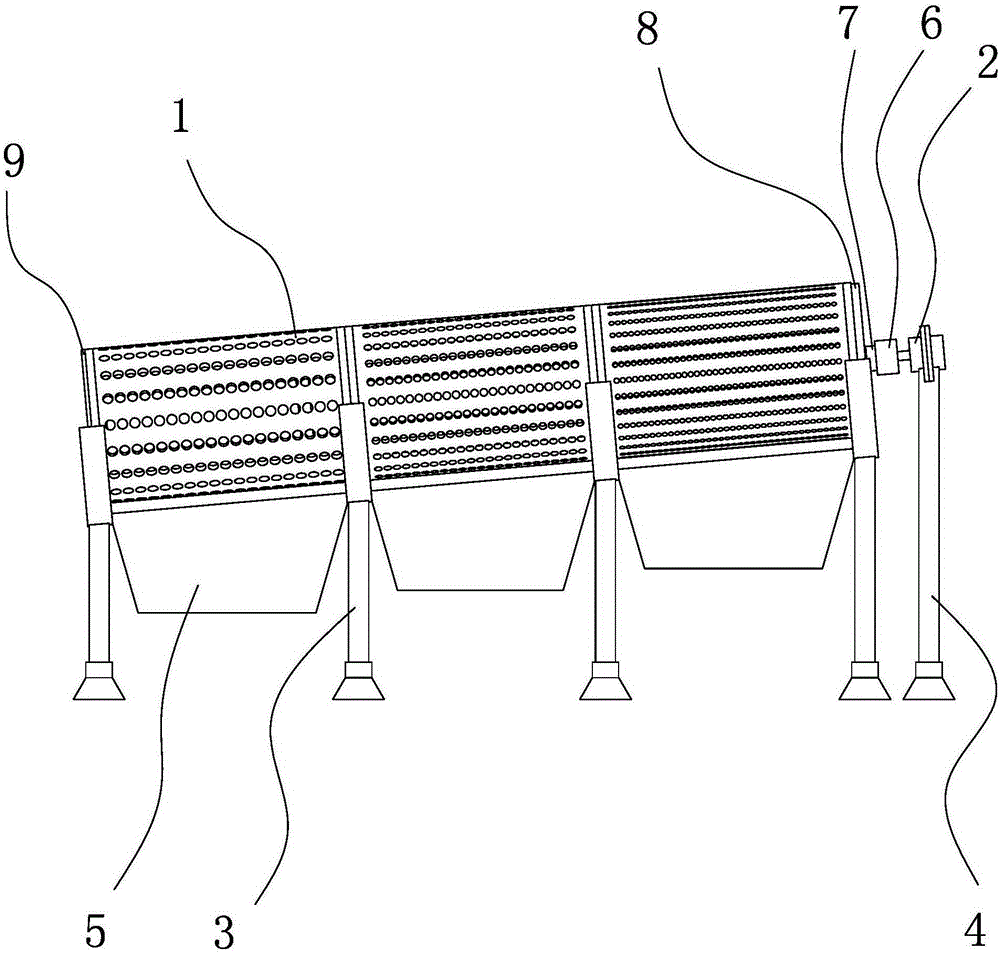

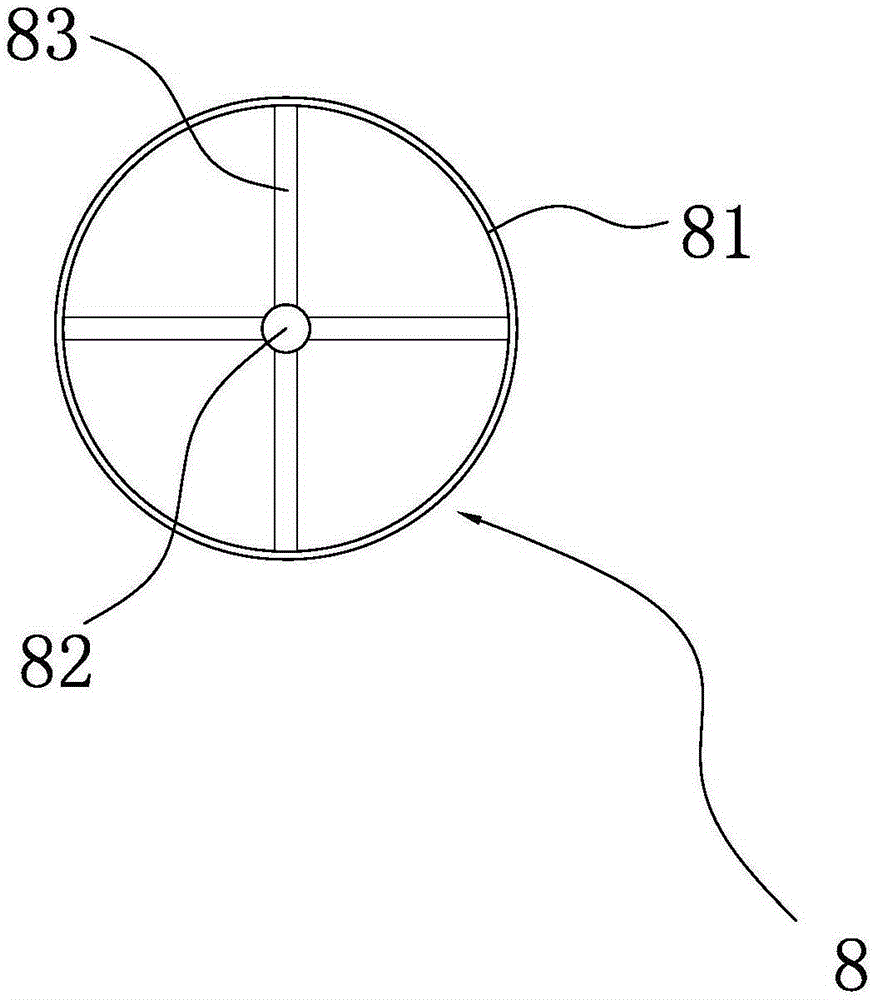

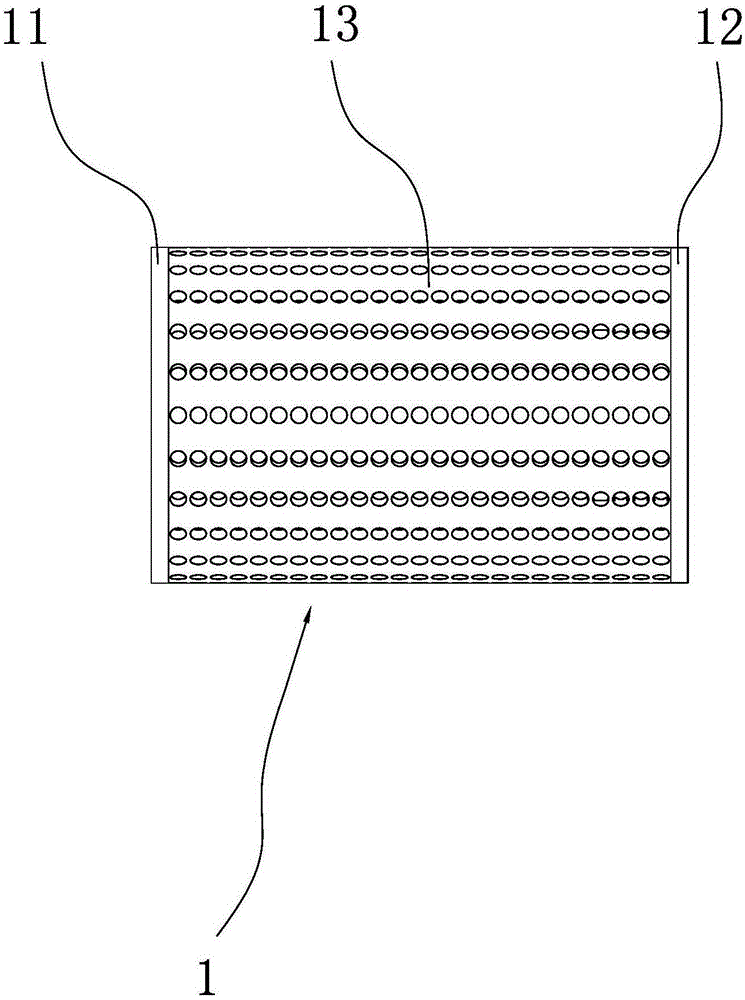

[0032] refer to figure 1, this embodiment is a graded screening device for screening ceramsite, including a frame, three sequentially connected drum screens 1 and a motor 2 for driving the drum screen 1 to rotate, and the frame includes a frame for supporting The four supports one 3 of the trommel 1 and one support two 4 for supporting the motor 2, the apertures of the screens 13 of each trommel 1 are different, and the apertures of the screens 13 of each trommel 1 connected in series are determined by It increases sequentially from the back to the front. The trommel 1 at the rear end is connected to the motor 2. Each trommel 1 is set on the same axis, and the two adjacent trommels 1 are fixedly connected. The bottom of each trommel 1 is Connect with a receiving hopper 5. Each trommel 1 is connected in series in sequence and fixed together. The trommel 1 at the rear end is the first stage, and the motor 2 drives the first stage trommel 1 to rotate, and the trommel 1 at each l...

Embodiment 2

[0038] combine Figure 8 , the structure of the second embodiment is basically the same as that of the first embodiment, the difference is that an arc-shaped buckle 34 is connected to the support base 32, and one end of the buckle 34 is hinged on one side of the mounting groove 321, and the buckle The other end of the ring 34 has a buckle 341 that can be detachably connected to the other side wall of the installation groove 321 . After the buckle 34 is connected with the support seat 32, the trommel 1 can be further limited to prevent the trommel 1 from shifting or jumping during the rotation process, and because the buckle 34 can be opened and closed relative to the installation groove 321, it is convenient Clean and maintain the trommel 1.

Embodiment 3

[0040] combine Figure 9 , The structure of the third embodiment is basically the same as that of the first embodiment, the difference is that the top of the trommel 1 is also covered with an arc-shaped dust cover 10 . The dust cover 10 can not only cover the dust generated by the vibration of the ceramsite, but also prevent the ceramsite from causing harm to the staff.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com