High-temperature pellet cooling device

A technology of cooling devices and pellets, which is applied in the field of metallurgical equipment, can solve problems such as energy waste, and achieve the effects of avoiding large energy consumption, eliminating unorganized steam emissions and deposition, and preventing internal deposition and bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

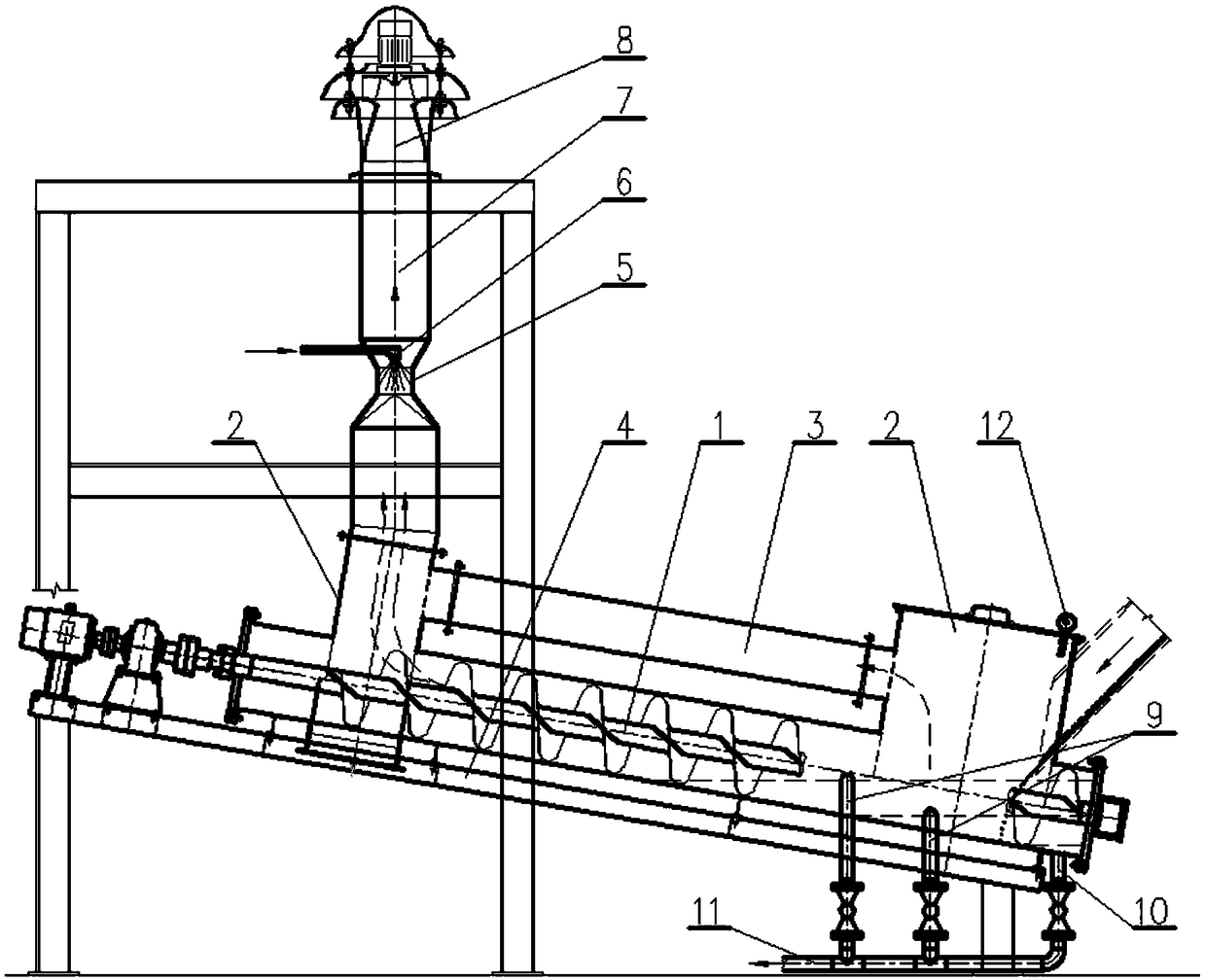

[0021] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0022] As shown in the figure, the high-temperature pellet cooling device in the present invention includes a screw discharge device 1, and the feed end of the screw discharge device 1 is provided with a water tank, which is arranged obliquely on the machine in such a way that the discharge end is higher than the feed end. On the frame 4; also includes a steam cooling device, the steam cooling device is not only connected with the gas collecting hood 2 at the inlet and outlet ends of the screw discharge device 1 through the communication pipe 3, but also communicated with the atmosphere. After the high-temperature pellets are quenched and cooled by the spiral discharge device, they are taken out and drained, and discharged through the discharge port. The steam generated during the water quenching process is sent to the steam cooling device t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com