Improved structure of blender in polymerization kettle

A stirrer and internal stirring technology, which is applied to pressure vessels used in chemical processes, mixers with rotary stirring devices, mixers, etc., can solve problems such as easy generation of gel, shortened tank cleaning period, and reduced heat transfer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

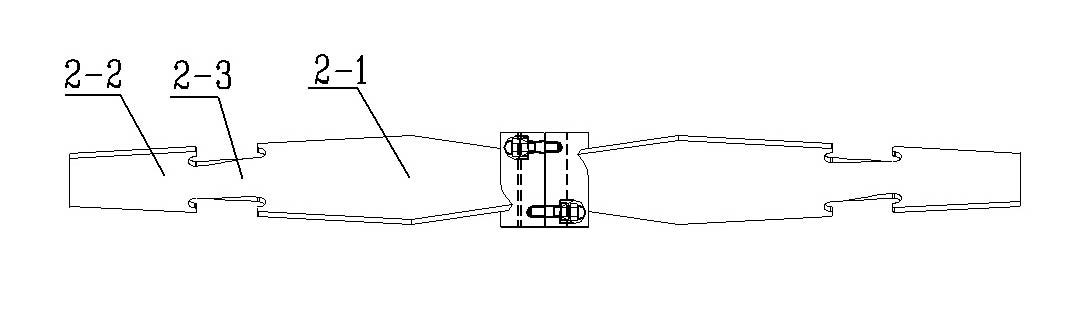

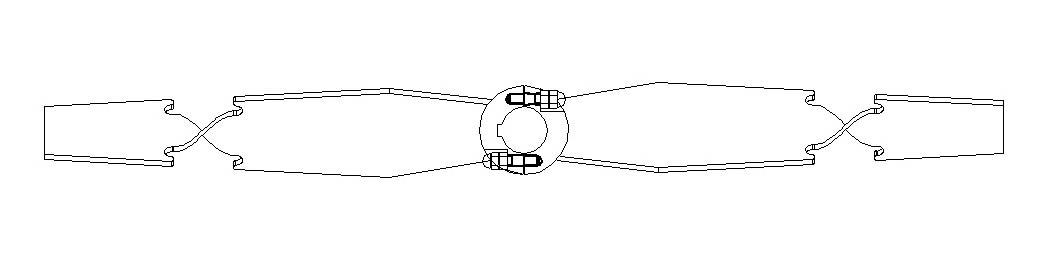

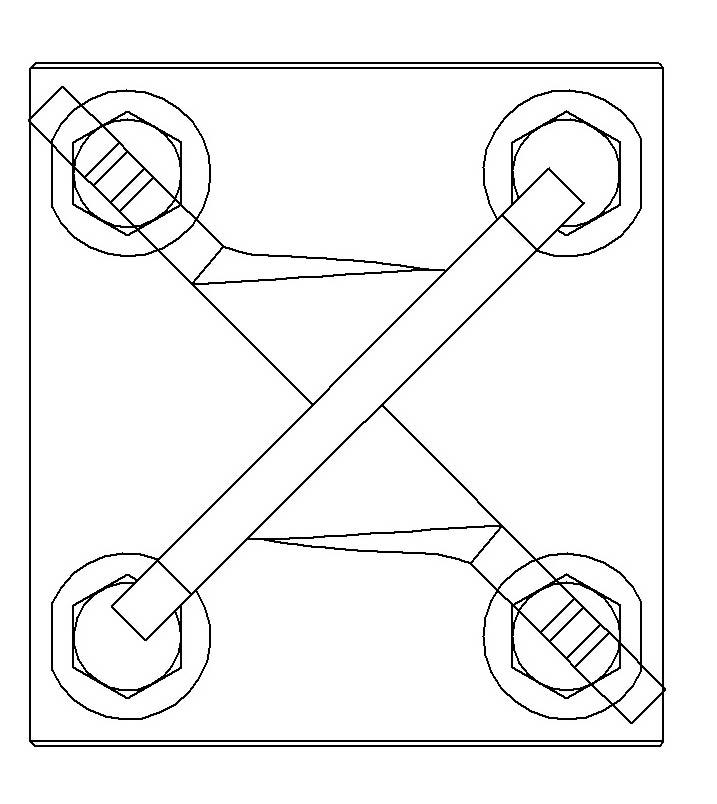

[0012] See figure 1 , figure 2 , image 3 , Figure 4 , including the reactor body, stirring shaft 1, and agitator. The agitator includes a slanted-blade paddle agitator 2 and a wide-blade paddle agitator 3 located at the lower head. The agitator is fixed on the stirring shaft 1. The blades of the device 2 include an inner half blade 2-1 and an outer half blade 2-2 respectively, and the inner half blade 2-1 and the outer half blade 2-2 maintain an angle after being twisted at the joint, and the oblique blades At the junction of the inner half blade 2-1 and the outer half blade 2-2 of the paddle agitator 2, four gaps are opened at four points on the edge, and the part surrounded by the four gaps is the inner half blade The twist section 2-3 between 2-1 and the outer half blade 2-2, when twisted, the inner half blade 2-1 does not move, only needs to clamp the outer half blade 2-2 to rotate, twist Section 2-3 just twists, and it is easier to implement twisting through four g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com