Rough polishing process for reducing overall flatness of gallium arsenide double-polished sheet

A gallium arsenide and flatness technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of constant removal rate and increased flatness of gallium arsenide double-throwing wafers, so as to reduce the polishing pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

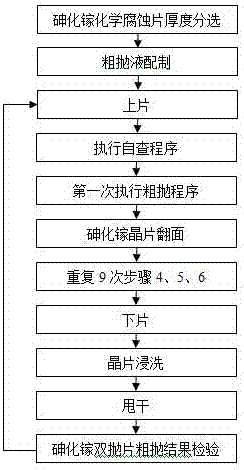

[0025] Embodiment 1: A rough polishing process for reducing the overall flatness of gallium arsenide double-throwing wafers is carried out according to the following steps:

[0026] In the first step, GaAs double-throwing wafers are sorted by 7 thicknesses, the sorting thickness is 700±5µm, every group of 10 pieces, and the thickness difference is less than or equal to 3µm.

[0027] In the second step, weigh 15L of deionized water with a 5L measuring cup and pour it into a clean coarse liquid throwing bucket, use a 1000ml measuring cup to weigh 600ml of NaClO solution and pour it into 15L of deionized water, stir the glass rod clockwise for 10 laps, and then weigh it with a 1000ml measuring cup Amount of 800ml containing SiO with a particle size of 85µm 2 The particle solution was poured into the previously prepared solution, and the glass rod was stirred clockwise for 10 laps.

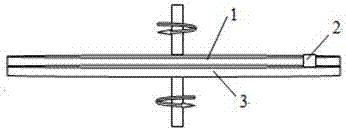

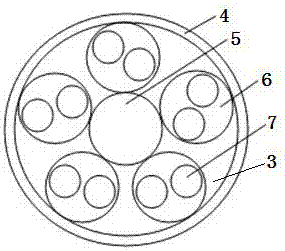

[0028] The third step is to put an epoxy resin planetary wheel 6 on the surface of the lower poli...

Embodiment 2

[0042] Example 2: The difference between this embodiment and Example 1 is: Step 2: 800ml NaClO solution, 1000ml containing SiO with a particle size of 85µm 2 Particle solution, other steps and parameters are the same as in Example 1.

Embodiment 3

[0043] Embodiment 3: The difference between this embodiment and Embodiment 1 is: in step 5, the liquid application pipe 2 sends a rough throwing liquid flow rate of 7.0ml / s, the third stage rough throwing time is 900s, the pressure is 50kg, and the pressurization time is 30s. The rotation speed of the ring gear 5 is 15 rpm, the rotation speed of the outer ring gear 4 is 25 rpm, and the rotation speed of the lower polishing disc 3 is 35 rpm. Other steps and parameters are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com