Pb (Ni1/3 Nb2/3) O3-Pb (Zr, Ti) O3 ceramic powder sintered under low temperature and fabrication method thereof

A ceramic powder, low-temperature sintering technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of high powder cost, reduced sintering temperature, and reduced material properties. Excellent ferroelectric properties, lower sintering temperature, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

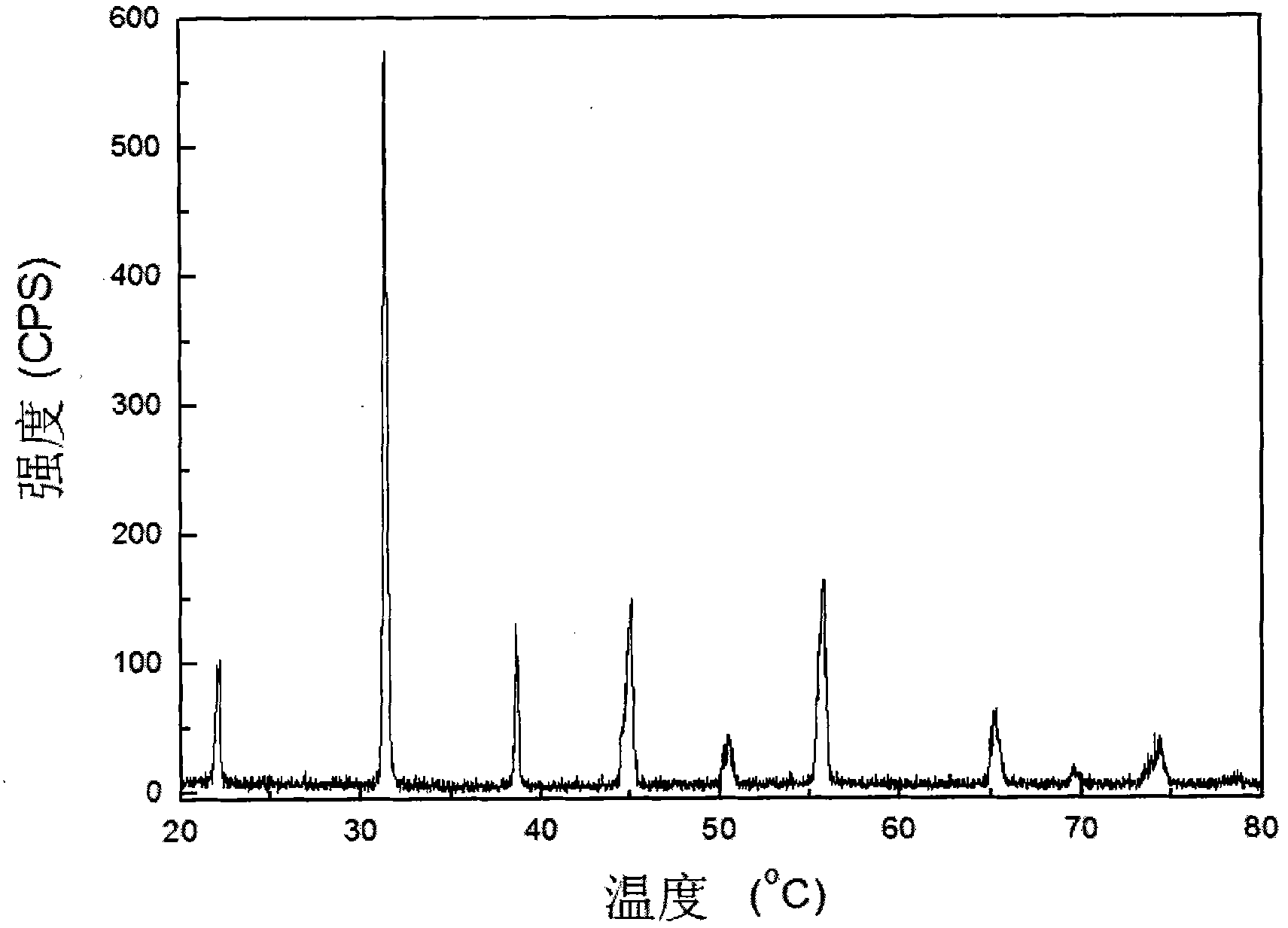

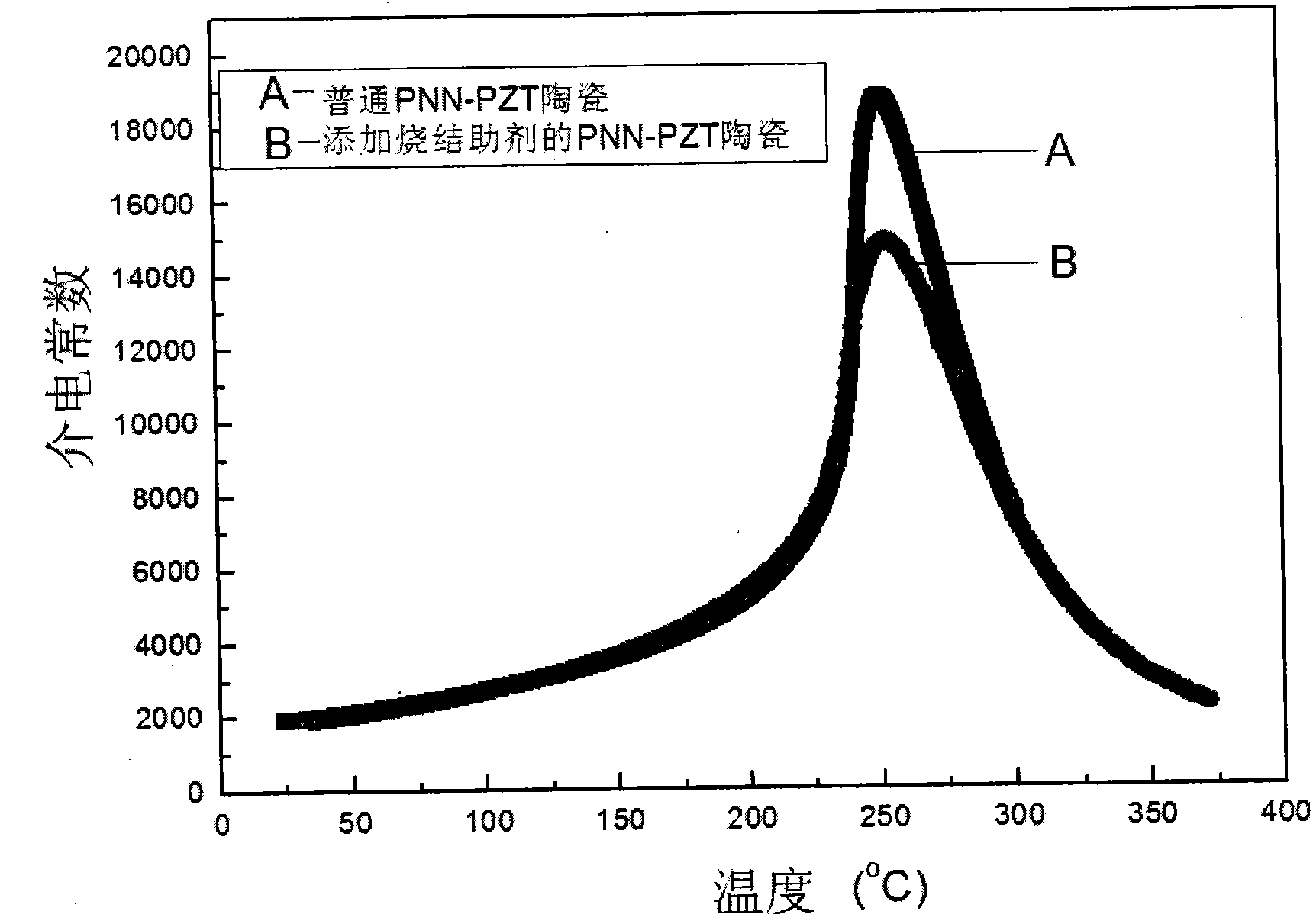

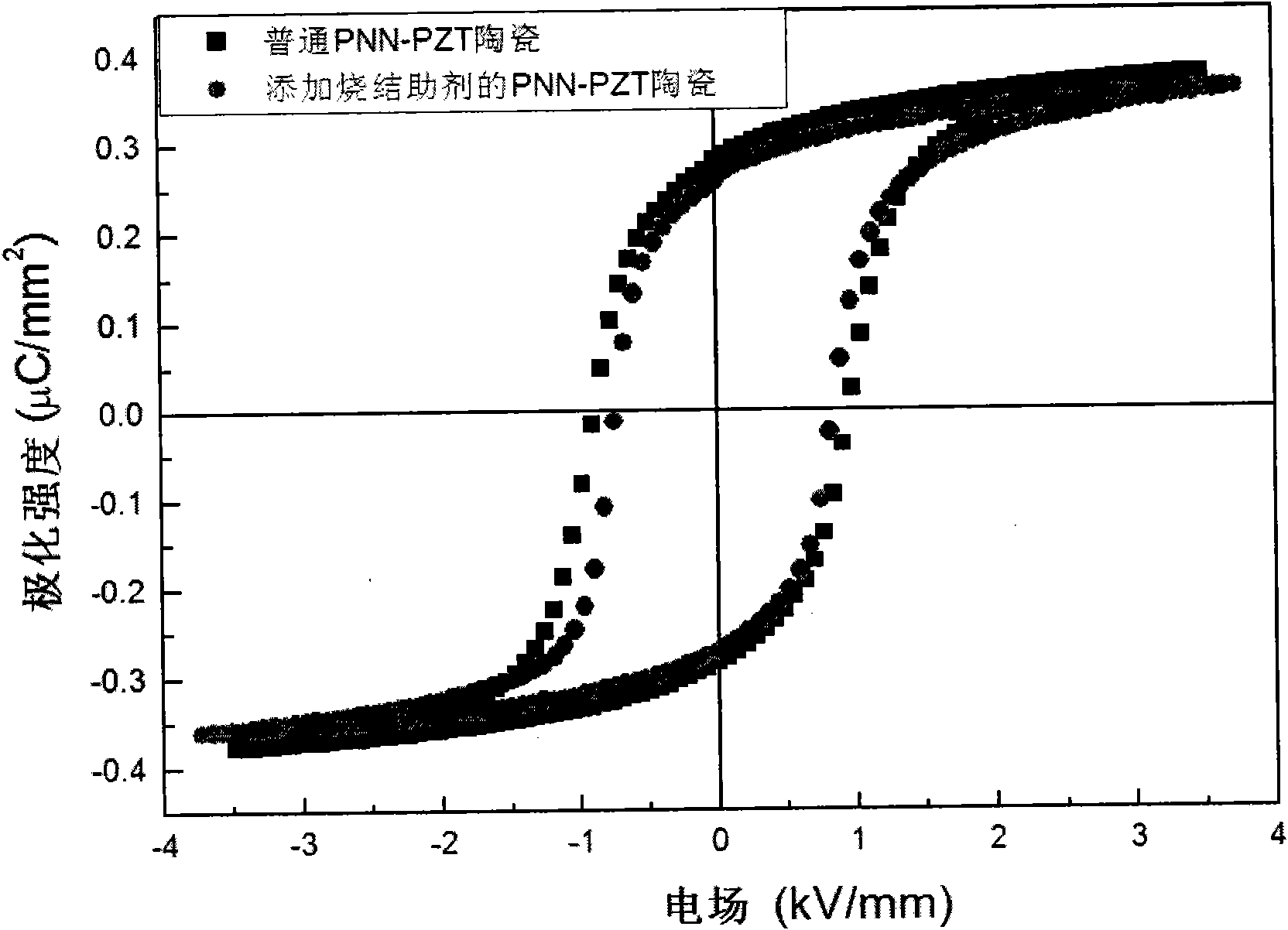

[0027] Embodiment 1: Pb(Ni 1 / 3 Nb 2 / 3 ) 0.30 (Zr 0.443 Ti 0.557 ) 0.70 o 3 +1%wt LiBiO 2 +0.08% wt CuO

[0028] (1) First use industrial raw material Pb 3 o 4 , NiO, Nb 2 o 5 , ZrO 2 、TiO 2 According to the above chemical formula ingredients, mixed by ball mill for 4 hours, the powder was fully dried and synthesized at 800°C for 2 hours, and then ball milled again for 6 hours to obtain PNN-PZT ceramic powder;

[0029] (2) Using analytically pure Li 2 CO 3 、 Bi 2 o 3 , CuO raw material, according to the above-mentioned chemical composition ingredients, mixed by ball mill for 4 hours and then dried to obtain low-temperature sintered PNN-PZT ceramic powder;

[0030] (3) The above-mentioned low-temperature sintered PNN-PZT ceramic powder is added with 8% binder containing 5% PVB, formed by dry pressing, and sintered at 950°C to obtain ceramics with good piezoelectric properties.

[0031] The electrical properties of the piezoelectric ceramics prepared above are s...

Embodiment 2

[0035] Embodiment 2: Pb(Ni 1 / 3 Nb 2 / 3 ) 0.30 (Zr 0.443 Ti 0.557 ) 0.70 o 3 +1%wt Ba(Cu 0.5 W 0.5 )O 3 +0.5%wtLiBiO 2 +0.08% wt CuO

[0036] (1) First use industrial raw material Pb 3 o 4 , NiO, Nb 2 o 5 , ZrO 2 、TiO 2 According to the above chemical formula ingredients, mixed by ball mill for 4 hours, the powder was fully dried and synthesized at 800°C for 2 hours, and then ball milled again for 6 hours to obtain PNN-PZT ceramic powder;

[0037] (2) Use analytically pure raw material BaCO 3 , CuO and W 2 o 3 According to the chemical formula Ba(Cu 0.5 W 0.5 )O 3 The ingredients were mixed by ball milling for 4 hours, synthesized at 650°C for 2 hours, and the synthesized powder was ball milled again for 4 hours to obtain Ba(Cu 0.5 W 0.5 )O 3 Powder;

[0038] (3) Using PNN-PZT ceramic powder, Ba(Cu 0.5 W 0.5 )O 3 Powder, Analytical Pure Li 2 CO 3 、 Bi 2 o 3 , CuO is mixed according to the above chemical composition, mixed by ball mill for 4 hours ...

Embodiment 3

[0043] Embodiment 3: Pb(Ni 1 / 3 Nb 2 / 3 ) 0.20 (Zr 0.7 Ti 0.3 ) 0.80 o 3 +2%wtBa(Cu 0.5 W 0.5 )O 3 +0.05%wtCuO

[0044] (1) First use industrial raw material Pb 3 o 4 , NiO, Nb 2 o 5 , ZrO 2 、TiO 2 According to the above chemical formula ingredients, mixed by ball mill for 4 hours, the powder was fully dried and synthesized at 800°C for 2 hours, and then ball milled again for 6 hours to obtain PNN-PZT ceramic powder;

[0045] (2) Use analytically pure raw material BaCO 3 , CuO and W 2 o 3 According to the chemical formula Ba(Cu 0.5 W 0.5 )O 3 The ingredients were mixed by ball milling for 4 hours, synthesized at 650°C for 2 hours, and the synthesized powder was ball milled again for 4 hours to obtain Ba(Cu 0.5 W 0.5 )O 3 Powder;

[0046] (3) Using PNN-PZT ceramic powder, Ba(Cu 0.5 W 0.5 )O 3 The powder and CuO are mixed according to the above chemical composition, mixed by ball mill for 4 hours and then dried to obtain low-temperature sintered PNN-PZT ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com