Preparation method and application of ferroelectric film

A ferroelectric thin film and substrate electrode technology, applied in the field of ferroelectric thin film preparation, can solve the problems of poor compatibility, unfavorable environmental protection, difficult growth of PZT, etc., and achieve the effects of good compatibility, no cracks and low roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

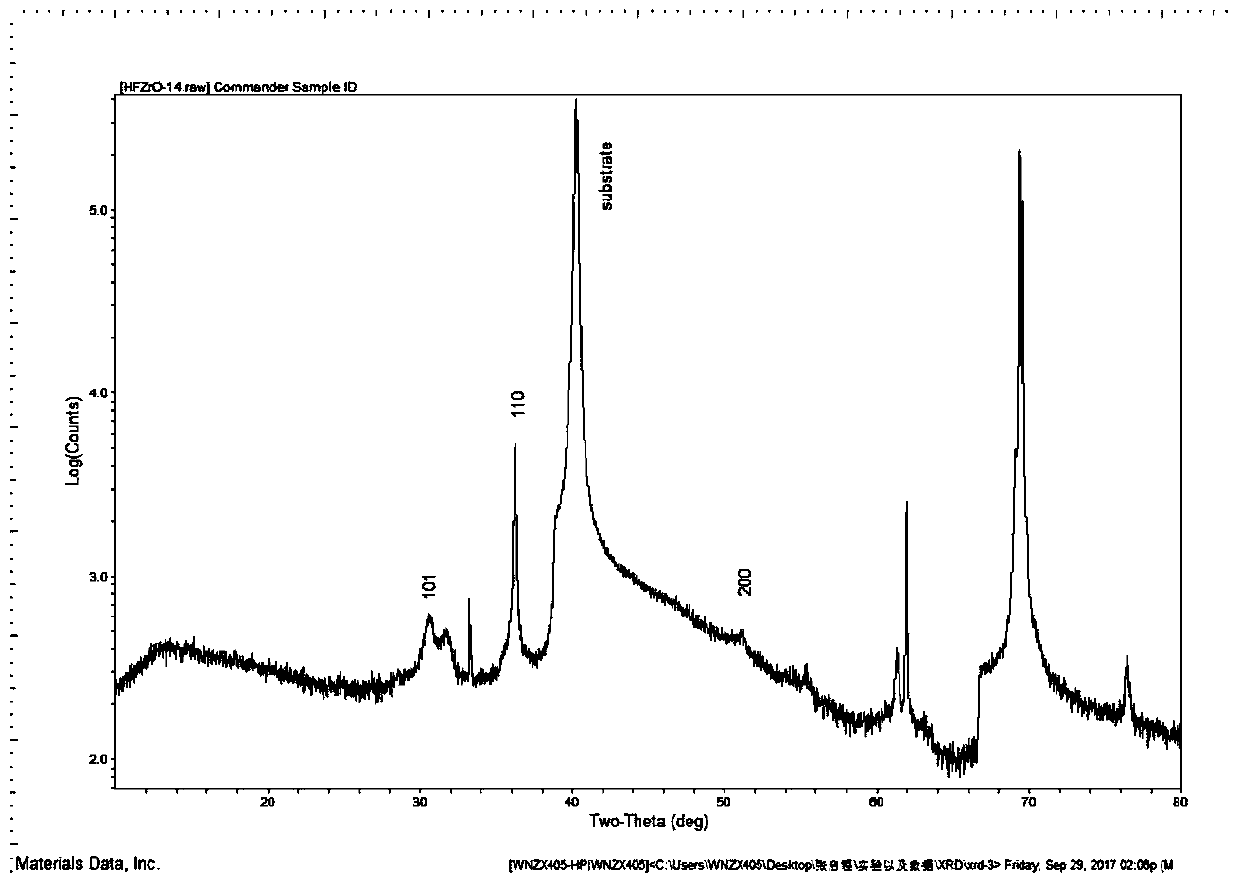

Embodiment 1

[0039] A method for preparing a ferroelectric thin film, comprising the steps of:

[0040] Step 1: Preparation of hafnium-zirconium oxide precursor solution: Weigh hafnium acetylacetonate (1.38g, 2.40mmol) and zirconium acetylacetonate (4.68g, 9.60mmol) and mix well, add acetic acid and acetic anhydride mixed solution (30mL) , the mass ratio of acetic acid and acetic anhydride in the mixed solution of acetic acid and acetic anhydride is 3:1. The above mixture was placed in a helium atmosphere and heated to 150 ° C and continued to stir for 30 minutes to obtain a hafnium-zirconium oxide precursor solution (Hf 0.2 Zr 0.8 o 2 ).

[0041] Step 2: Coat the hafnium-zirconium oxide precursor solution on the titanium nitride electrode, then put it into a tube furnace, heat it to 350 °C at a speed of 10 °C / s, and dry and pyrolyze it for 10 minutes. furnace to obtain an amorphous film, and repeat the above operations until the desired film thickness of 150nm is reached;

[0042] Pu...

Embodiment 2

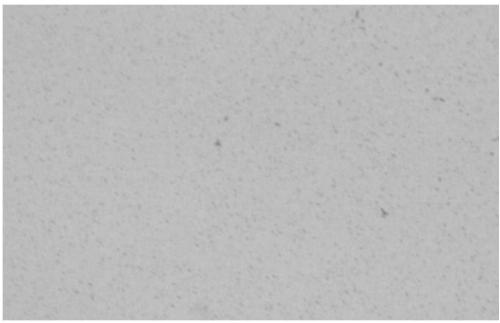

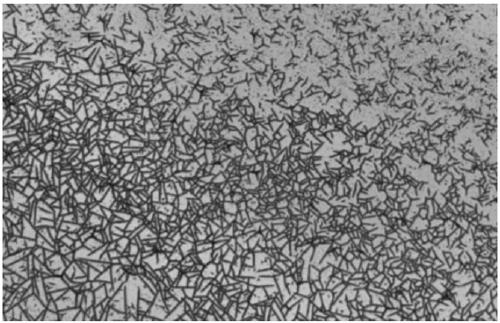

[0045] Example 2 The modified form of Example 1 is implemented, and the difference from Example 1 is that in the second step, the hafnium-zirconium oxide precursor solution is coated on a silicon oxide wafer, and magnified by 20 times with a confocal microscope Photographs of the surface of the ferroelectric thin film were taken afterward to observe the compatibility between the ferroelectric thin film and silicon. In this embodiment, a group of comparative experiments were also done, in which the hafnium-zirconium oxygen precursor solution was replaced by the PZT precursor solution (Pb(Zr 0.8 Ti 0.2 )O 3 ), where the ratio of zirconium to titanium Zr:Ti is 8:2, and the photo of the surface of PZT film was taken after magnifying 20 times with a confocal microscope.

Embodiment 3

[0047] A method for preparing a ferroelectric thin film, comprising the steps of:

[0048] Step 1: Preparation of hafnium-zirconium oxide precursor solution: Weigh hafnium acetylacetonate (3.45g, 6.00mmol) and zirconium acetylacetonate (2.93g, 6.00mmol) and mix well, add acetic acid and acetic anhydride mixed solution (30mL) , the mass ratio of acetic acid and acetic anhydride in the mixed solution of acetic acid and acetic anhydride is 3:1. The above mixture was placed in a helium atmosphere and heated to 150 ° C and continued to stir for 30 minutes to obtain a hafnium-zirconium oxide precursor solution (Hf 0.5 Zr 0.5 o 2 ).

[0049] Step 2: Coat the hafnium-zirconium oxide precursor solution on the titanium nitride electrode, then put it into a tube furnace, heat it to 350 °C at a speed of 10 °C / s, and dry and pyrolyze the tube for 10 minutes type furnace to obtain an amorphous film, and repeat the above operations until the desired film thickness of 150nm is reached;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com