Superlattice ferroelectric memristor based on HfO2/ZrO2 or HfO2/Al2O3 and preparation thereof

A technology of superlattice and memristor, applied in the field of ferroelectric memristor based on HfO2/ZrO2 or HfO2/Al2O3 superlattice and its preparation, can solve the problem of many internal defects in the film, increased device leakage current, dielectric constant Reduce the problem, achieve the effect of increasing the stability of ferroelectric performance, reducing leakage current, and optimizing ferroelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

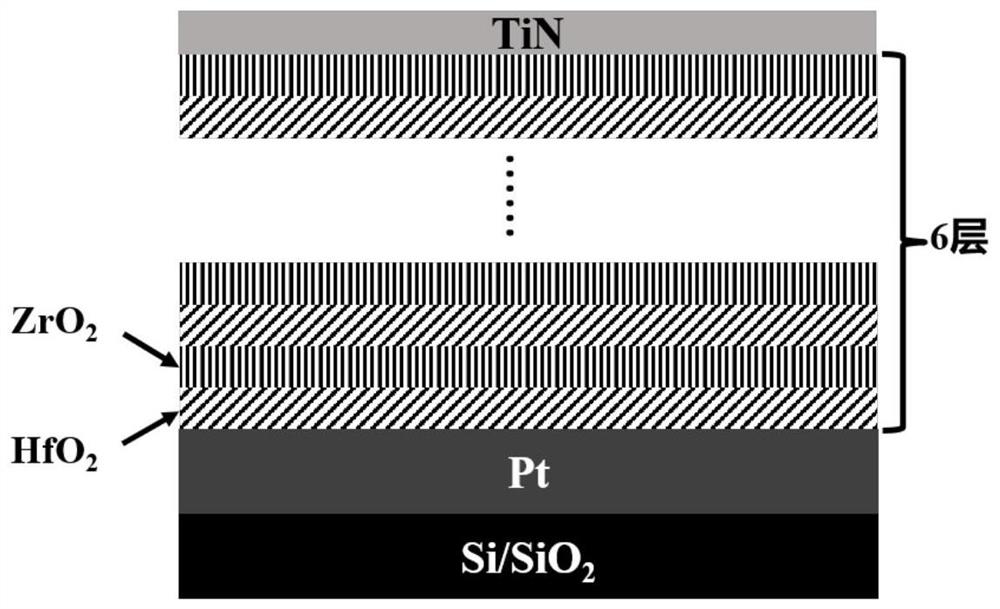

[0047] Embodiment 1: a kind of based on HfO 2 / ZrO 2 Preparation method of ferroelectric memristor with superlattice structure

[0048] Embodiment 1 provides HfO 2 / ZrO 2 The superlattice structure ferroelectric memristor, the device structure is TiN / ZrO 2 / HfO 2 / ZrO 2 / HfO 2 / ZrO 2 / HfO 2 / Pt, whose structure is as figure 1 As shown, 2nm thick HfO is preferred in this example 2 and 2nm thick ZrO 2 , a total of 6 floors. The lower electrode is made of Pt, and the upper electrode is made of TiN.

[0049] The HfO 2 / ZrO 2 Superlattice structure ferroelectric memristor preparation method; Concrete steps are as follows:

[0050] (1) The first step: substrate cleaning:

[0051] will be attached with SiO 2 The Si substrates were immersed in acetone and alcohol solutions and ultrasonically cleaned for 10 min, respectively. The samples were placed in plasma water and ultrasonically cleaned for 3 min.

[0052] (2) The second step: lower electrode preparation:

[00...

Embodiment 2

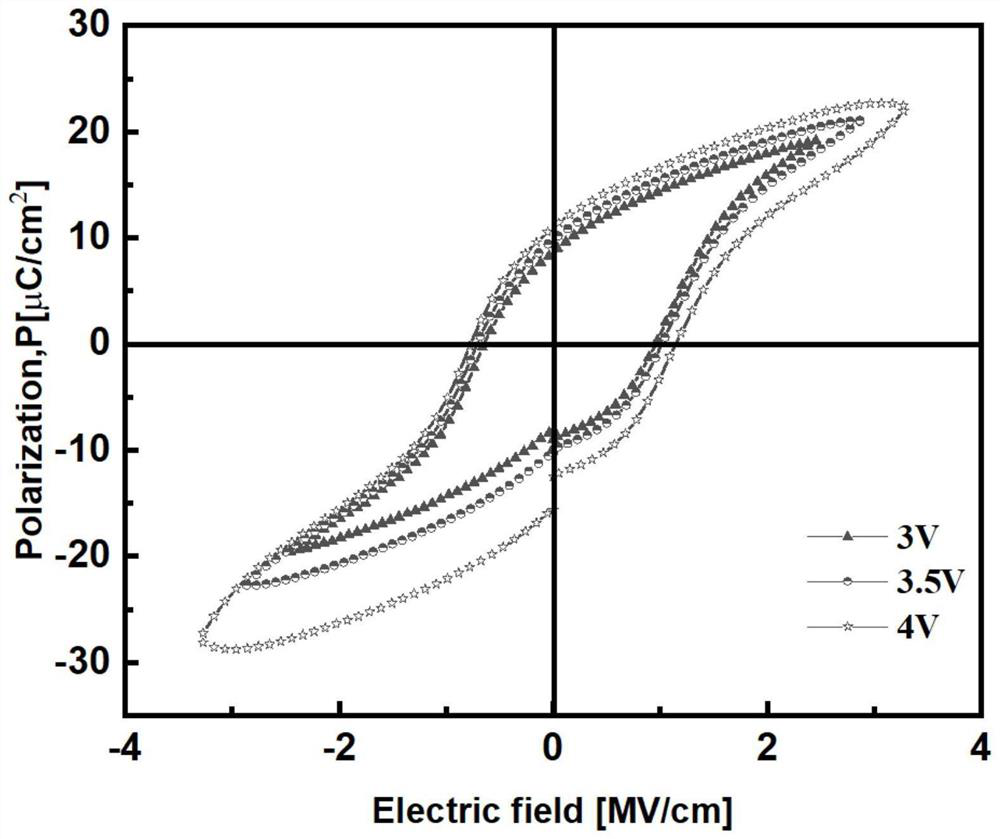

[0069] Embodiment 2 is substantially similar to Embodiment 1, and the main difference is that in the third step, when the functional layer is plated by ALD, the processes of ③ and ④ are cycled 4 times to obtain HfO with a total thickness of 16nm. 2 / ZrO 2 superlattice functional layer. like Figure 4 Shown is the ferroelectric characteristic P-E curve of Example 2 when the triangular pulse frequency is 100 Hz and the amplitude is ±4 V. When the thickness of the superlattice film increases, the remanent polarization of Example 2 is 12.37uC / cm 2 .

Embodiment 3

[0071] Embodiment 3 is substantially similar to Embodiment 1, and the main difference is that in the third step, when the functional layer is plated by ALD, the processes of ③ and ④ are cycled 5 times to obtain HfO with a total thickness of 20nm. 2 / ZrO 2 superlattice functional layer. like Figure 5 Shown is the cyclic ferroelectric characteristic P-E curve of Example 3 when the triangular pulse frequency is 100 Hz and the amplitude is ±4 V. When the thickness of the superlattice film increases, the remanent polarization of Example 3 is 6.58uC / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com