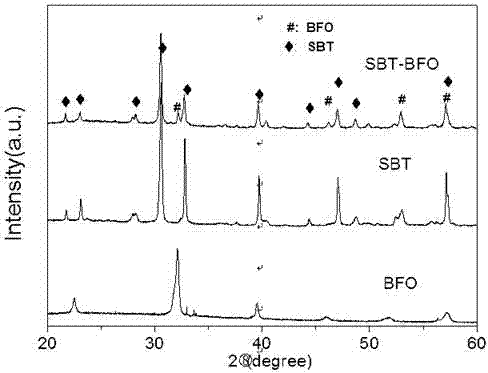

Bismuth ferrite-strontium bismuth titanatemultiferroic composite film and preparation method thereof

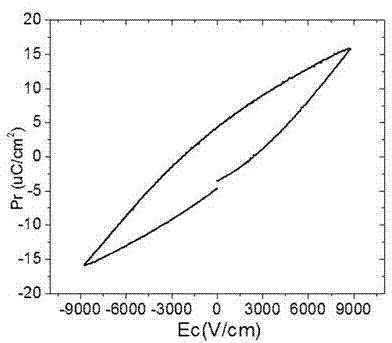

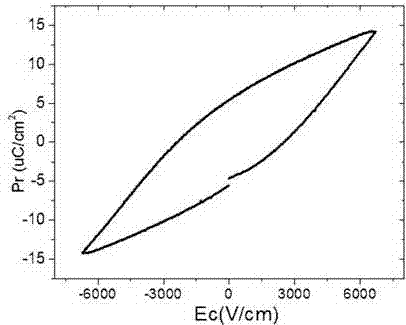

A composite film, strontium bismuth titanium technology, applied in the field of electronic ceramics, can solve the problems that the ferroelectric domain cannot be reversed, the ferroelectric performance cannot be displayed, and the saturated polarization cannot be obtained, so as to reduce the leakage current density, improve the stability, Effect of Improving Ferroelectric Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below through specific examples.

[0028] The bismuth ferrite-strontium bismuth titanium multiferroic composite film includes the following raw materials: iron nitrate, bismuth nitrate, tetrabutyl titanate and strontium acetate.

[0029] The preparation method of the bismuth ferrite-strontium bismuth titanium multiferroic composite film comprises the following steps:

[0030] (1) Prepare the precursor solution of bismuth ferrite: first weigh 3.6727g of powdered ferric nitrate and 4.8753g of bismuth nitrate, then add 10ml of acetylacetone as a chelating agent, and then add 10ml of ethylene glycol as a solvent; use a magnetic stirrer Fully stir for 7 hours until dissolved; finally add 10ml of glacial acetic acid to adjust the pH value to 0.3, and obtain a transparent, uniform and stable red bismuth ferrite precursor solution after stirring for 24 hours. The concentration of the bismuth ferrite precursor solution is 0.3 mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com