Method for preparing titanium dioxide hollow micro-sphere

A hollow microsphere, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high cost, difficult to large-scale industrial production, complex preparation process, etc., and achieves short production cycle, reduced production cost, and synthetic simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

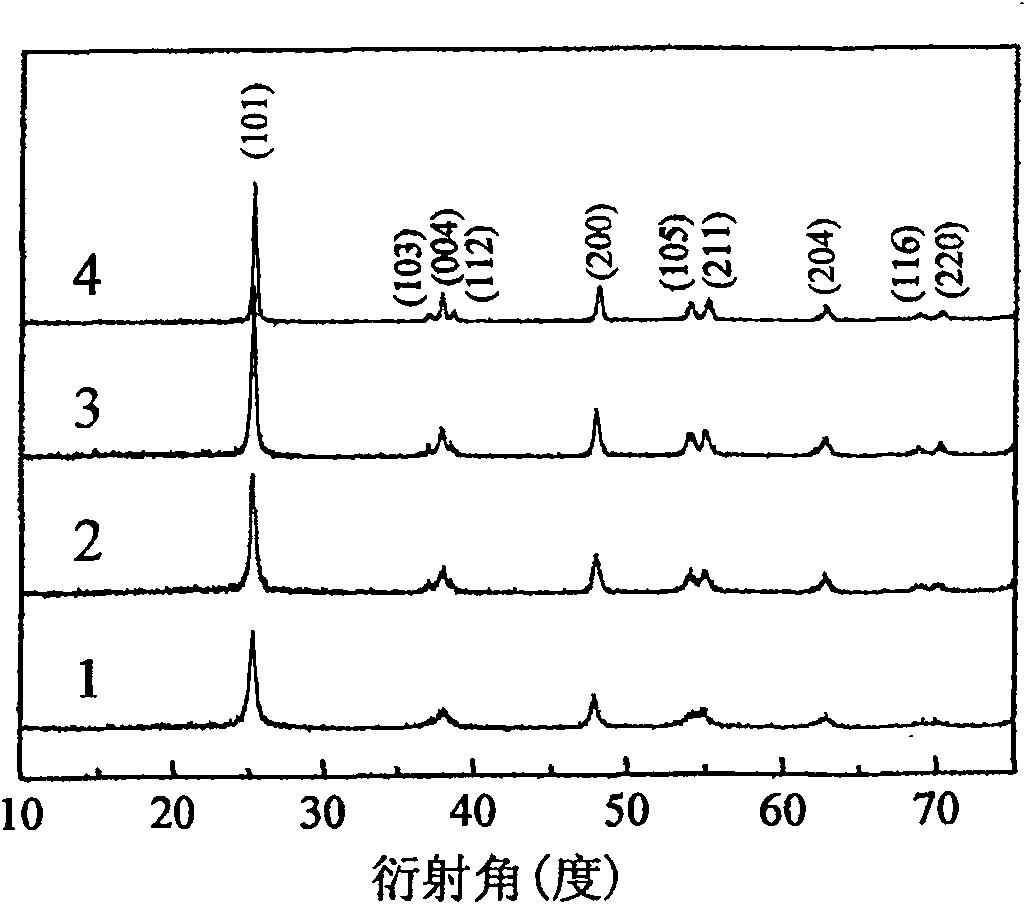

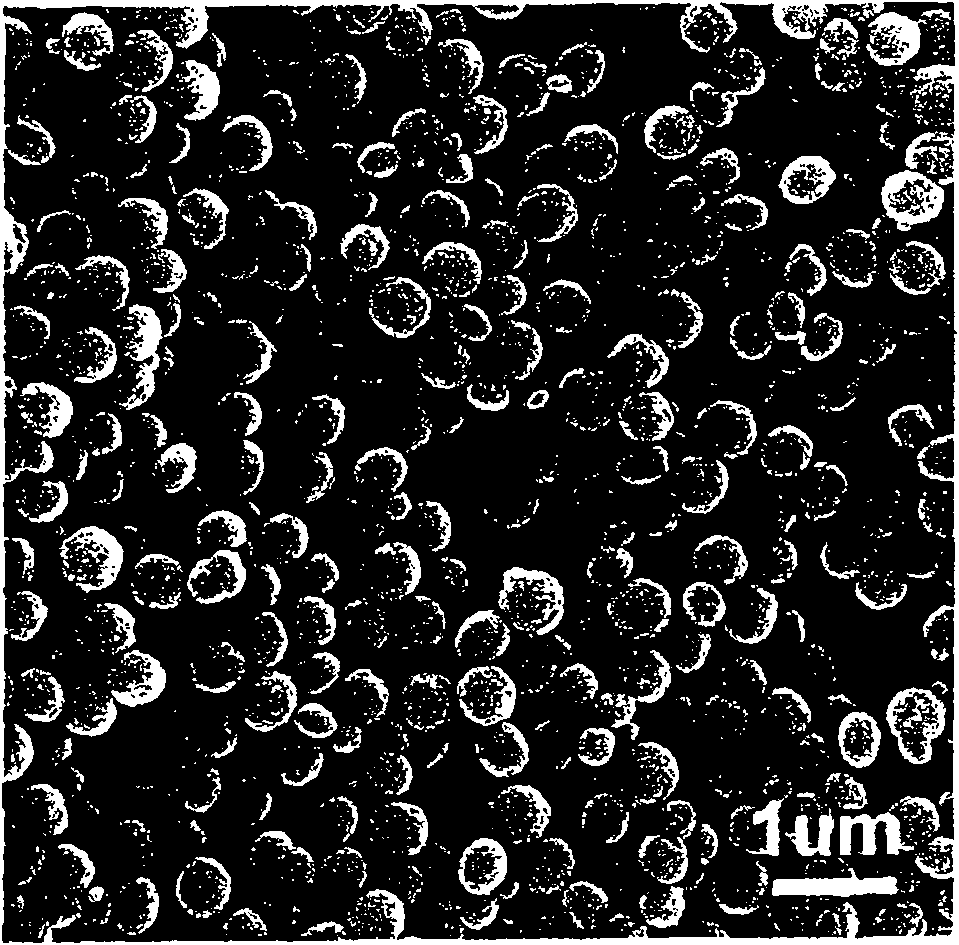

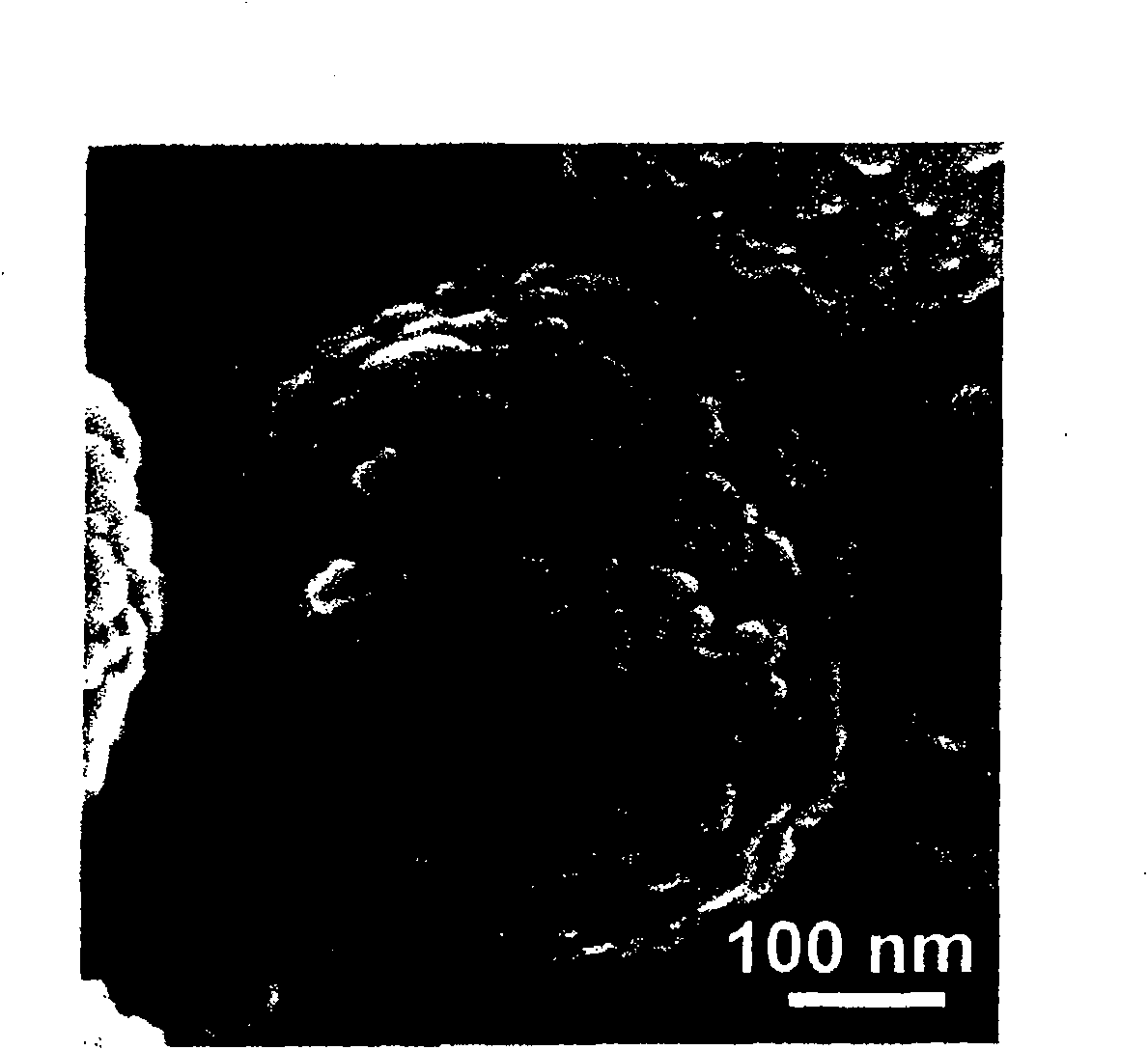

[0025] Put 10mL industrial titanium solution (manufactured by Guangzhou Titanium Dioxide Factory) into a 20mL autoclave lined with polytetrafluoroethylene, hydrothermally react at 140°C for 24h, and wash with distilled water and absolute ethanol in turn after cooling , After filtering, a white solid product was obtained, and the product was dried at 60° C. for 24 hours to obtain 1.18 g of titanium dioxide hollow microspheres. attached figure 1 Middle curve 1 is the X-ray diffraction pattern of the product obtained in this embodiment, as can be seen from the figure, the peak position of each diffraction peak is similar to that of anatase type TiO 2 The phases of the diffraction peaks on the standard card (JCPDS No.84-1286) are consistent, and no impurity peaks appear, indicating that the product is pure anatase structure TiO 2 . attached figure 2 It is the low-magnification SEM figure of the product obtained in this embodiment, from figure 2 It can be seen from the figure...

Embodiment 2

[0027] Put 10mL of industrial titanium liquid (manufactured by Guangzhou Titanium Dioxide Factory) into a 20mL autoclave lined with polytetrafluoroethylene, hydrothermally react at 180°C for 12h, and wash with distilled water and absolute ethanol in turn after cooling , After filtering, a white solid product was obtained, and the product was dried at 80° C. for 18 hours to obtain 1.20 g of titanium dioxide hollow microspheres. attached figure 1 Middle curve 2 is the X-ray diffraction figure of gained product, can find out from the figure, the peak position of each diffraction peak and anatase type TiO 2 The phases of the diffraction peaks on the standard card (JCPDS No.84-1286) are consistent, and no impurity peaks appear, indicating that the product is pure anatase structure TiO 2 .

Embodiment 3

[0029] Put 10mL of industrial titanium liquid into a 20mL autoclave lined with polytetrafluoroethylene, hydrothermally react at 220°C for 4 hours, wash with distilled water and absolute ethanol in turn after cooling, and obtain a white solid product after filtration. The product was dried at 100° C. for 12 hours to obtain 1.10 g of titanium dioxide hollow microspheres. attached figure 1 Middle curve 3 is the X-ray diffraction figure of obtained product, can find out from the figure, the peak position of each diffraction peak and anatase type TiO 2 The phases of the diffraction peaks on the standard card (JCPDS No.84-1286) are consistent, and no impurity peaks appear, indicating that the product is pure anatase structure TiO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com