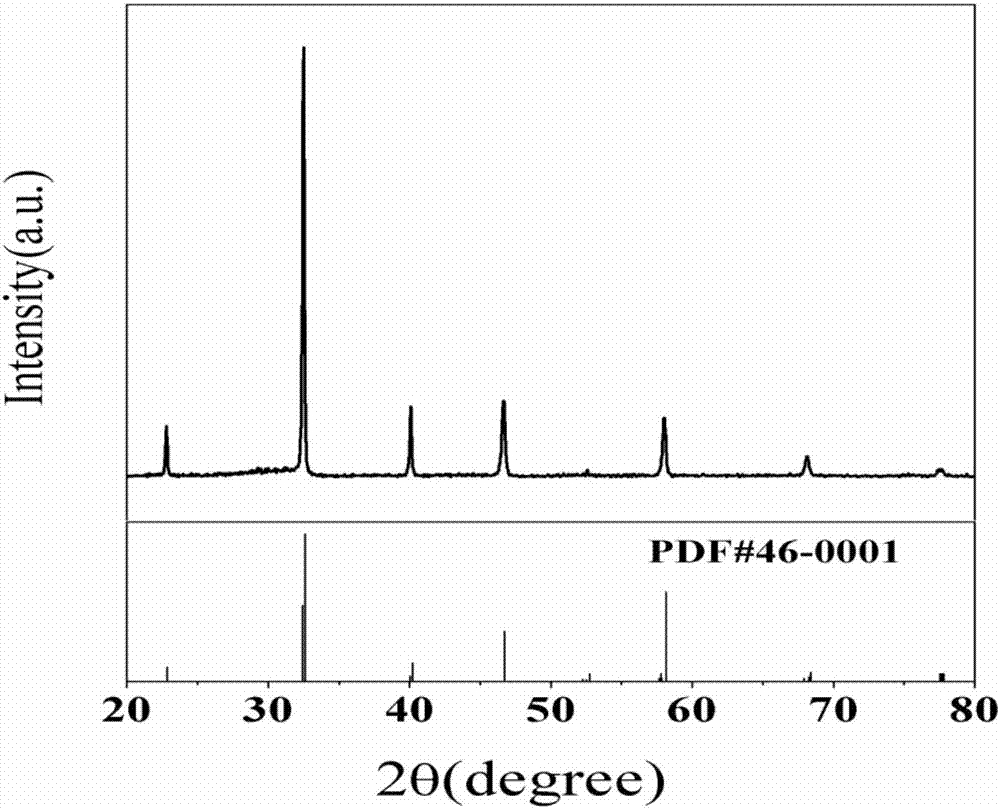

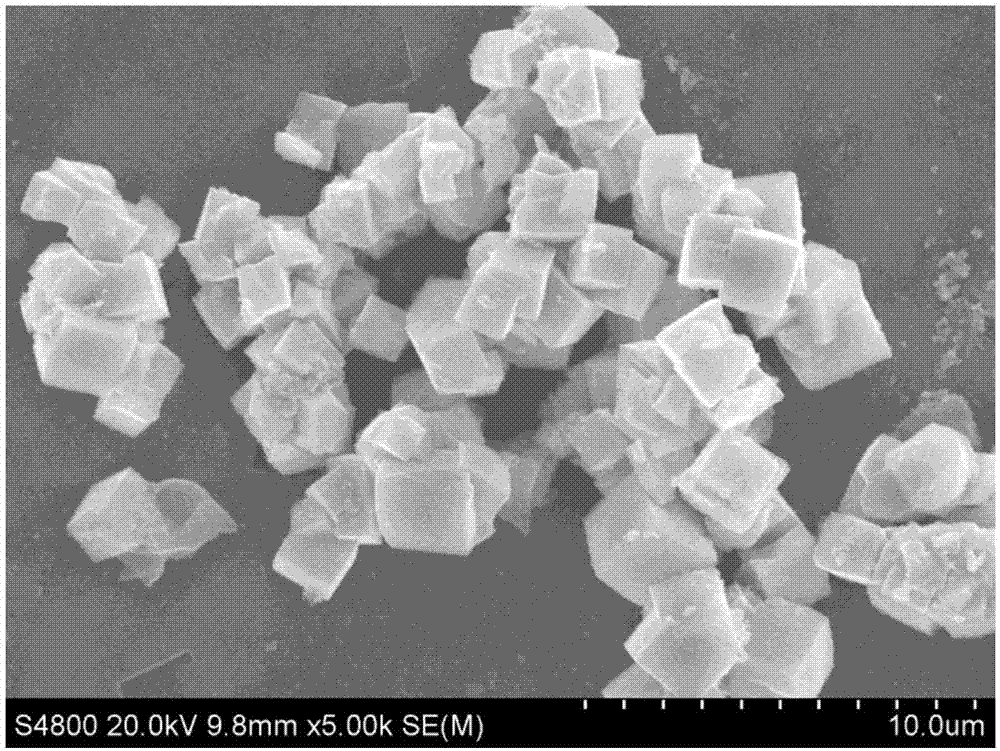

Method for quickly preparing cubic sodium bismuth titanate at low temperature

A cubic sodium bismuth titanate, rapid technology, applied in the direction of titanate, chemical instruments and methods, titanium compounds, etc., can solve the problems of difficulty in obtaining fine particles, high sintering temperature of samples, poor ceramic compactness, etc., and achieve reaction The effect of shortening the time, uniform particle distribution and reducing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] A kind of method for rapidly preparing cubic sodium bismuth titanate powder under low temperature of the present invention comprises the following steps,

[0034] (1) configure NaOH clear solution, in the solution, the concentration of NaOH is 12mol / L;

[0035] (2) Configure Bi(NO 3 ) 3 ·5H 2 O solution, in solution, Bi(NO 3 ) 3 ·5H 2 The concentration of O is 0.1mol / L, and an appropriate amount of nitric acid is dropped into the solution, and the stirring is continued until Bi(NO 3 ) 3 ·5H 2 O completely dissolves, and obtains clear solution A; Used nitric acid is 1ml in this preferred example;

[0036] (3) Use a pipette to transfer Ti(OC 4 h 9 ) 4 Added dropwise into clear solution A to obtain mixed solution B, in which Ti(OC 4 h9 ) 4 and Bi(NO in step (2) 3 ) 3 ·5H 2 The molar ratio of O is 1:1;

[0037] (4) After the mixed solution B in the step (3) is magnetically stirred, then the NaOH clarified solution is added dropwise to the mixed solution B, ...

example 2

[0041] A kind of method for rapidly preparing cubic sodium bismuth titanate powder under low temperature of the present invention comprises the following steps,

[0042] (1) configure NaOH clear solution, in the solution, the concentration of NaOH is 14mol / L;

[0043] (2) Configure Bi(NO 3 ) 3 ·5H 2 O solution, in solution, Bi(NO 3 ) 3 ·5H 2 The concentration of O is 0.2mol / L, and an appropriate amount of nitric acid is dropped into the solution, and the stirring is continued until Bi(NO 3 ) 3 ·5H 2 O dissolves completely, obtains clear solution A; Used nitric acid is 2ml in this preferred example;

[0044] (3) Use a pipette to transfer Ti(OC 4 h 9 ) 4 Added dropwise into clear solution A to obtain mixed solution B, in which Ti(OC 4 h 9 ) 4 and Bi(NO in step (2) 3 ) 3 ·5H 2 The molar ratio of O is 1:1.5;

[0045] (4) After the mixed solution B in the step (3) is magnetically stirred, then the NaOH clarified solution is added dropwise to the mixed solution B, ...

example 3

[0049] The present invention rapidly prepares cubic Na at a low temperature 0.5 Bi 0.5 TiO 3 The method for the powder comprises the following steps, (1) configuring NaOH clarified solution, in the solution, the concentration of NaOH is 15mol / L;

[0050] (2) Configure Bi(NO 3 ) 3 ·5H 2 O solution, in solution, Bi(NO 3 ) 3 ·5H 2 The concentration of O is 0.1mol / L, and an appropriate amount of nitric acid is dropped into the solution, and the stirring is continued until Bi(NO 3 ) 3 ·5H 2 O dissolves completely, obtains clear solution A; Used nitric acid is 1.5ml in this preferred example;

[0051] (3) Use a pipette to transfer Ti(OC 4 h 9 ) 4 Added dropwise into clear solution A to obtain mixed solution B, in which Ti(OC 4 h 9 ) 4 and Bi(NO in step (2) 3 ) 3 ·5H 2 The molar ratio of O is 3:4;

[0052] (4) After the mixed solution B in the step (3) is magnetically stirred, then the NaOH clarified solution is added dropwise to the mixed solution B, and then sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com