Kitchen refuse coking treatment process and apparatus

A kitchen waste and treatment device technology, which is applied in the field of kitchen waste resource treatment, can solve kitchen waste pollution and other problems, and achieve the effects of high treatment efficiency, good promotion adaptability, and simple and hygienic treatment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

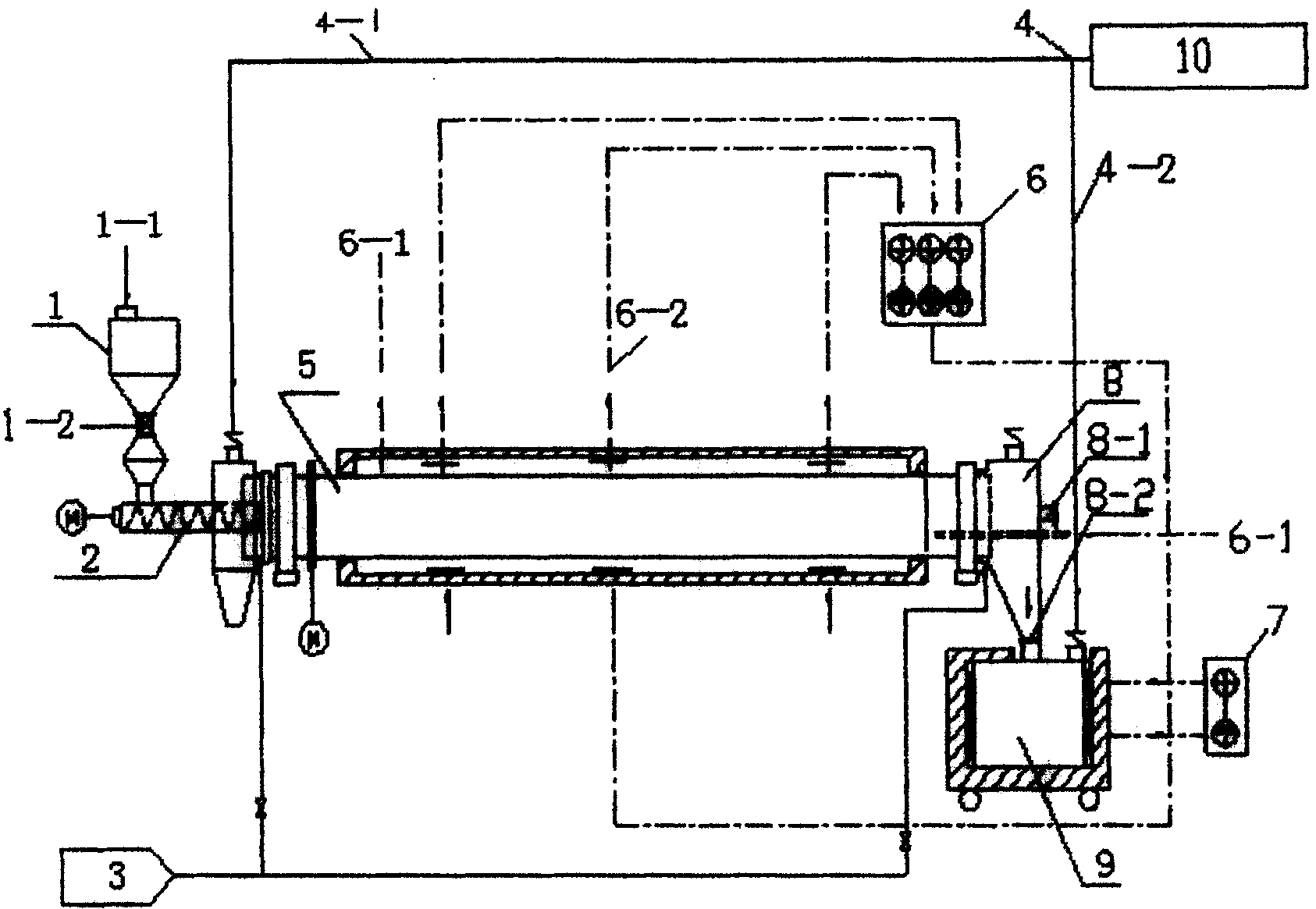

Method used

Image

Examples

Embodiment 1

[0042] Simulate the coking process of kitchen waste, and use the experimental method of small batch reactor to accurately test the coking data of kitchen waste. The raw material is kitchen waste, crushed to less than 0.5mm, and preheated to 200°C after removing impurities. Then the temperature is rapidly raised to 500°C in the heating furnace. After sufficient reaction and fractional distillation, the product yields obtained are shown in Table 1.

[0043] Table 1 Kitchen waste coking product yield (wt%)

[0044] raw material

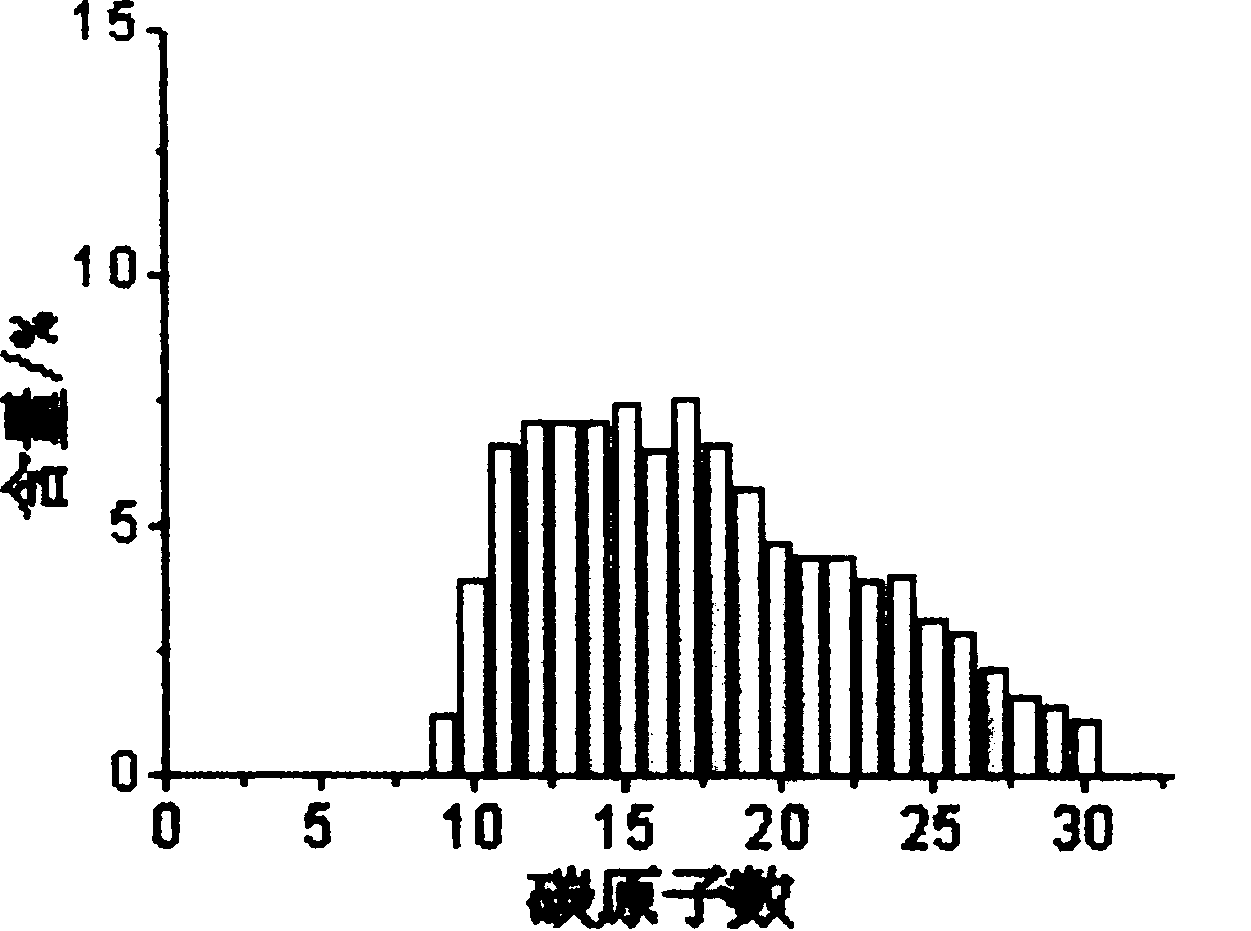

[0045] Refer to Ministry of Petroleum Standard SY / T5119-1995 "Analysis Method for Soluble Organic Matter in Rocks and Crude Oil Group Components" to carry out group chromatography analysis of liquid product (kitchen waste tar). The asphaltene in the sample was dissolved with chloroform, and after the chloroform volatilized, it was precipitated and filtered with n-pentane to obtain asphaltene. The soluble matter was passed through silica gel a...

Embodiment 2

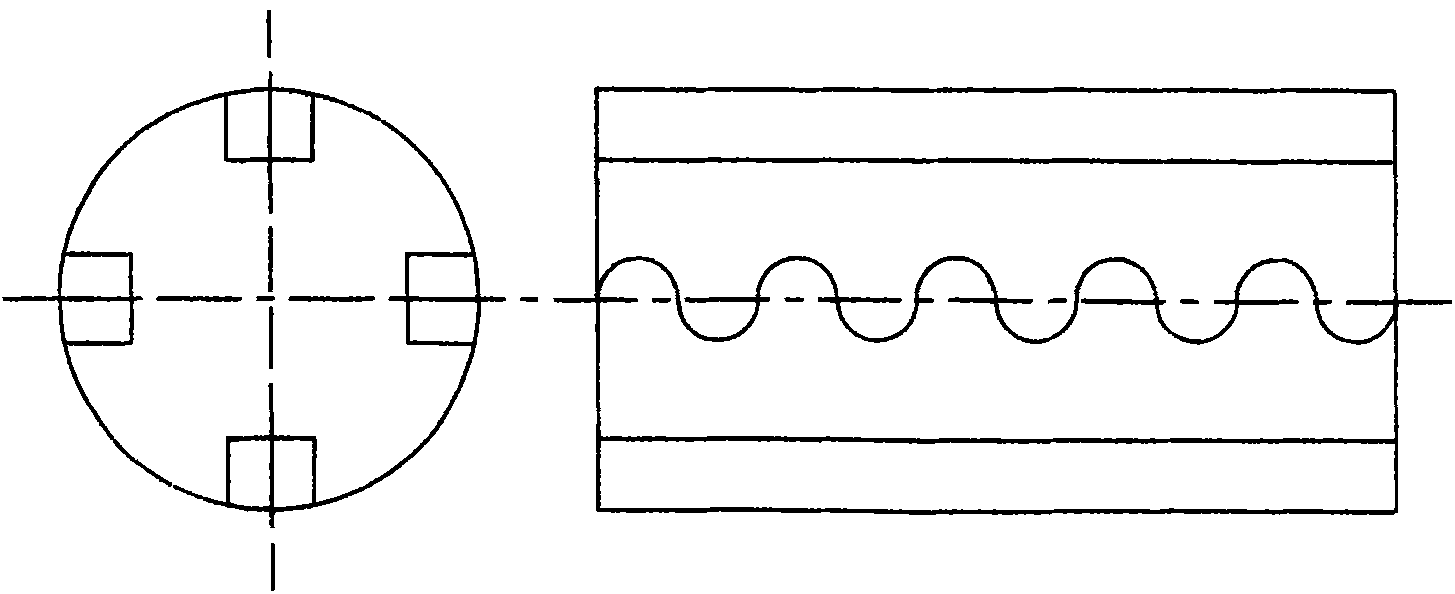

[0050] The coking reaction was carried out in a drum-type heating reaction furnace, and the yield of three-phase products was measured. The raw material is kitchen waste, crushed to less than 2mm, and preheated to 200°C after removing impurities. Then it enters the drum-type heating reaction furnace through the feeding system and rapidly raises the temperature to 500°C, and is transported to the high-temperature storage tank after reaction. After sufficient reaction and fractional distillation, the product yields obtained are shown in Table 3.

[0051] Table 3 Kitchen waste coking product yield (wt%)

[0052] raw material

[0053] The yield of the most economically valuable solid product (kitchen coke) was 33.2%, and the yield of liquid product (kitchen tar) was 48.2%, both of which accounted for 81.4% of the total mass of the whole kitchen waste. It shows that the effect of the coking process is very good, and it has high economic and production value.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com