Large-scale production process for paper surface gypsum boards with annual yield scale being 50 million square meters

A paper-faced gypsum board and production process technology, applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of high fuel and gas energy consumption, blank production process, long construction period, etc., to reduce the water-to-paste ratio and shorten the setting time. , to ensure the effect of energy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

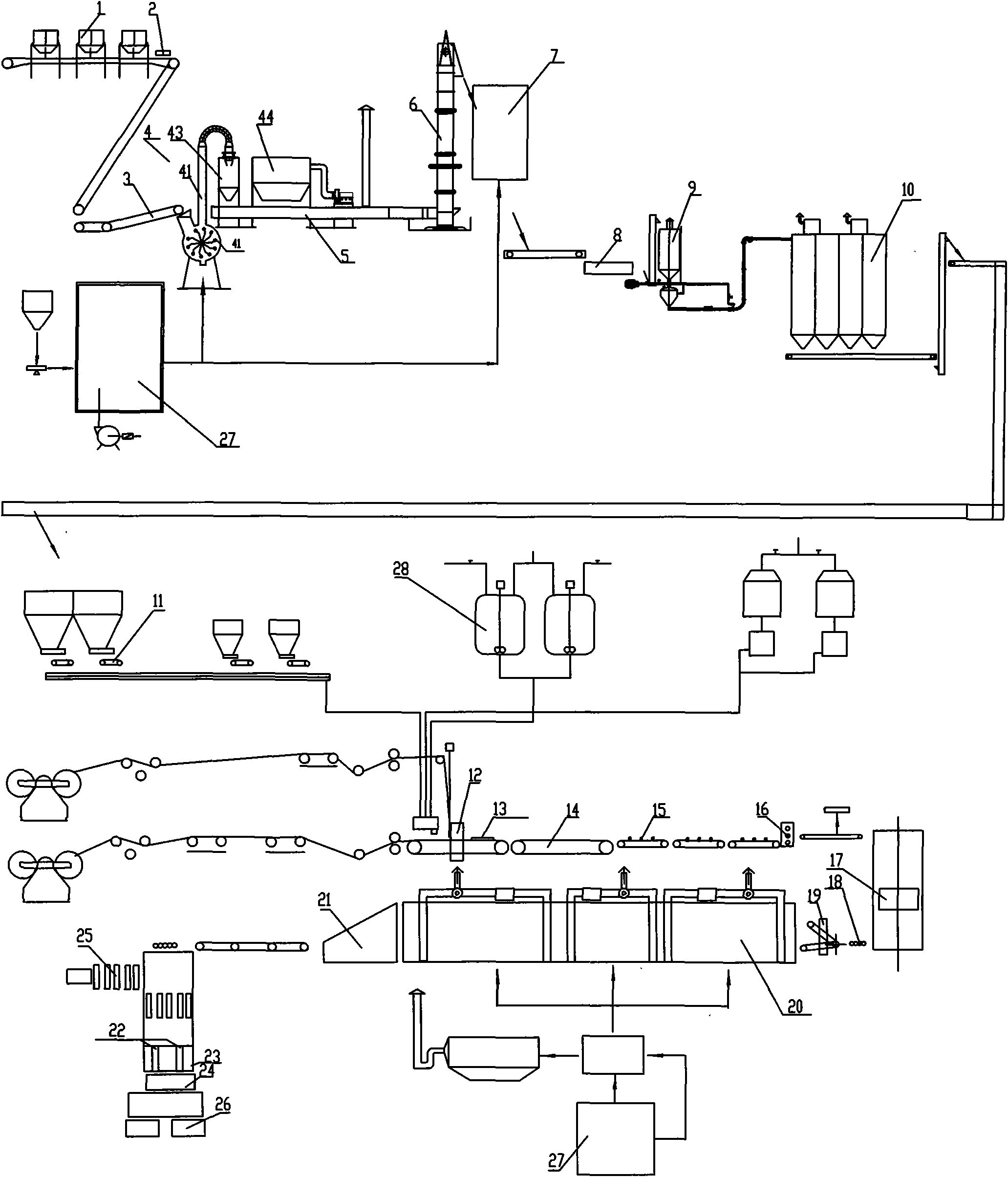

[0032] The process will be described in detail below in conjunction with the schematic diagram of device connection. The relevant technical content that is not mentioned can be adopted or borrowed from the existing technology, and the arrow indicates the conveying direction.

[0033] A large-scale gypsum board production process, comprising the following steps:

[0034] (1): Generation of building gypsum

[0035] 1.1, high-speed air drying

[0036] Desulfurization gypsum is used as raw material. Desulfurization gypsum contains a large amount of free water, and the weight percentage of water is 10-12%. The desulfurization gypsum enters the feeding bin, and after pre-homogenization in multiple pre-homogenization bins 1, the raw material is absorbed The ironware 2 removes impurities; then it passes through the dense roller belt conveyor 3 and is sent to the desulfurized gypsum air drying and rapid drying system 4.

[0037] The above-mentioned drying system 4 is composed of a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com