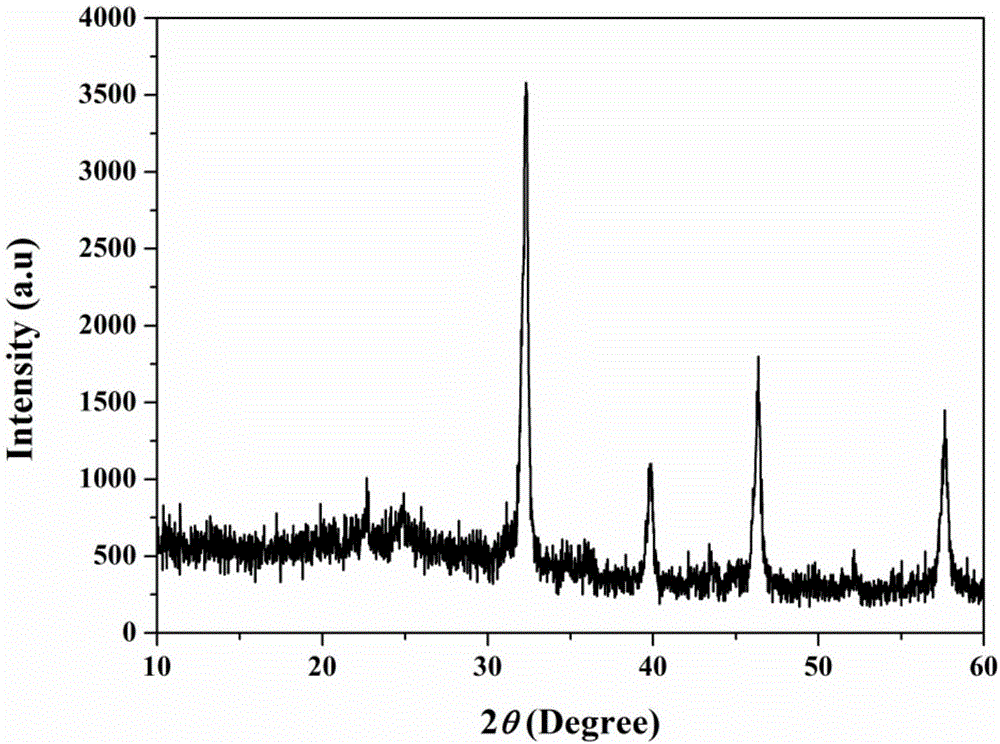

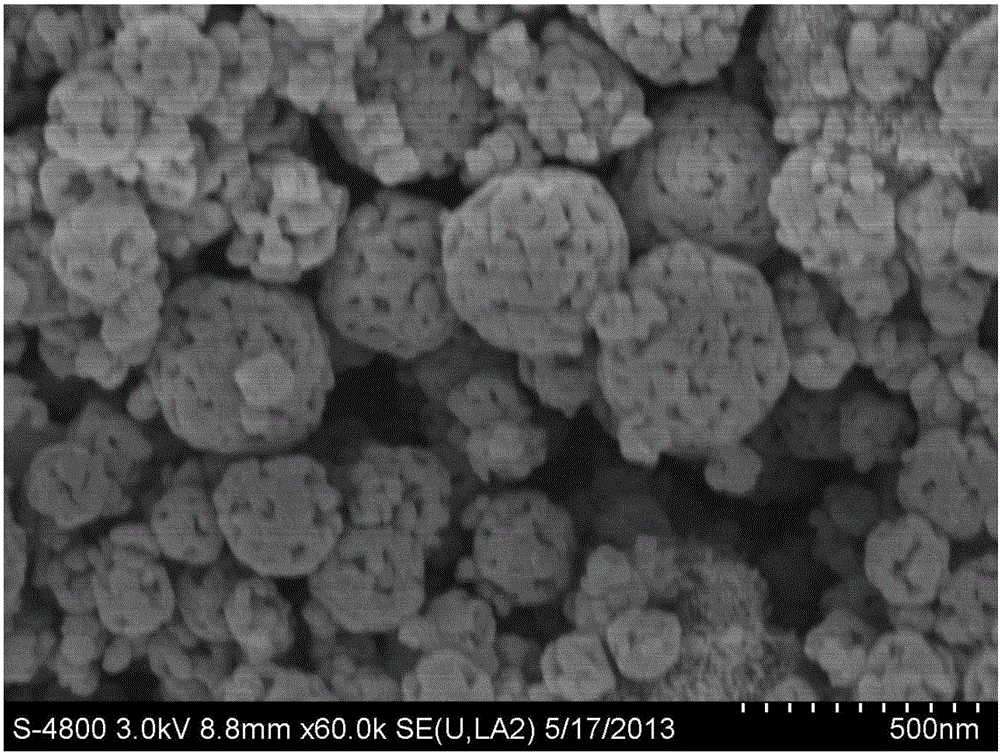

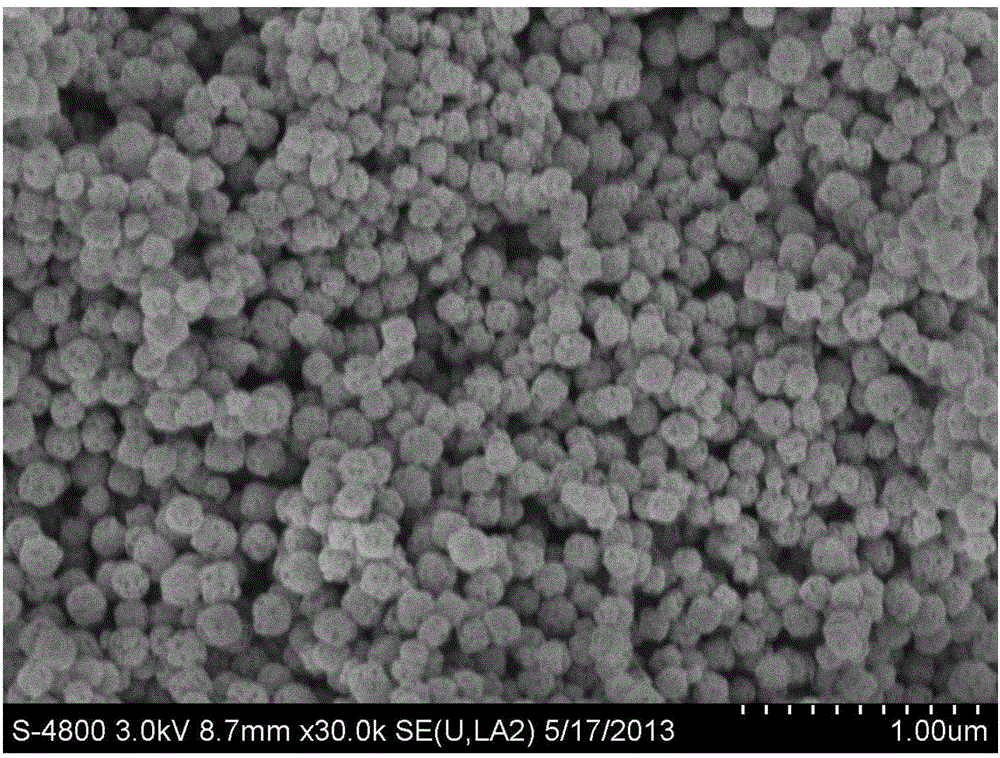

Preparation method of porous barium strontium titanate powder

A technology of barium strontium titanate and porous titanium, which is applied in the field of inorganic non-metallic functional materials, can solve the problems of non-dense microstructure, insufficient specific surface area, and poor uniformity, and achieve excellent size uniformity and dispersion, and good environmental friendliness high performance and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment is a preparation method of porous strontium barium titanate powder, comprising the following steps:

[0028] Step 1: Barium strontium titanate (Ba 1-x Sr x TiO 3 , BST) in the mass ratio of barium and strontium Ba / Sr=1, weigh 0.08mol / L of barium chloride (BaCl 2 ) and 0.08mol / L strontium nitrate [Sr(NO 3 ) 2 ] to prepare 20 ml of an aqueous solution with a total concentration of Ba and Sr ions of 0.16 mol / L. Then add 2.0 mol / L mineralizer potassium hydroxide (KOH) to the above solution, stir for 30 min until it is fully dissolved and mixed uniformly, then transfer the above mixed solution to one of the polytetrafluoroethylene double-chamber linings. cavity;

[0029] Step 2: Weigh tetrabutyl titanate according to the Ti ratio of 0.04 mol / L in the entire reaction system, and then add a small amount of deionized water and dilute nitric acid solution to it to inhibit the hydrolysis of tetrabutyl titanate, and then prepare The resulting solution is tra...

Embodiment 2

[0036] This embodiment is a preparation method of porous strontium barium titanate powder, comprising the following steps:

[0037] Step 1: Barium strontium titanate (Ba 1-x Sr x TiO 3 , BST) in the mass ratio of barium and strontium Ba / Sr=5 / 3, weigh 0.10mol / L of barium chloride (BaCl 2 ) and 0.06mol / L strontium nitrate [Sr(NO 3 ) 2 ] to prepare 20 ml of an aqueous solution with a total concentration of Ba and Sr ions of 0.16 mol / L. Then add 2.0mol / L mineralizer potassium hydroxide (KOH) to the above solution, stir for 30 min until it is fully dissolved and uniformly mixed, then transfer the above mixed solution to a cavity lined with a polytetrafluoroethylene double cavity Inside;

[0038] Step 2: Weigh tetrabutyl titanate according to the Ti ratio of 0.04 mol / L in the entire reaction system, and then add a small amount of deionized water and dilute nitric acid solution to it to inhibit the hydrolysis of tetrabutyl titanate, and then prepare The solution was transferre...

Embodiment 3

[0045] This embodiment relates to a preparation method of porous strontium barium titanate powder, comprising the following steps:

[0046] Step 1: Barium strontium titanate (Ba 1-x Sr x TiO 3 , BST) in the mass ratio of barium and strontium Ba / Sr=1 / 3, weigh 0.04mol / L of barium chloride (BaCl 2 ) and 0.12mol / L strontium nitrate [Sr(NO 3 ) 2 ] to prepare 20 ml of an aqueous solution with an ion concentration at the A site (Ba+Sr) of 0.16 mol / L. Then add 2.0 mol / L mineralizer potassium hydroxide (KOH) to the above solution, stir for 30 min until it is fully dissolved and uniformly mixed, then transfer the above mixed solution to a cavity lined with a polytetrafluoroethylene double cavity Inside;

[0047] Step 2: Weigh tetrabutyl titanate according to the Ti ratio of 0.04 mol / L in the whole reaction system, and then add a small amount of deionized water and dilute nitric acid solution to it, so as to inhibit the hydrolysis of tetrabutyl titanate. The prepared solution is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com