Method for preparing gold nano particle modification zinc oxide

A technology of gold nanoparticles and zinc oxide, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problem of uneven dispersion of precious metal particles, complex preparation process, particle The problem of different particle sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

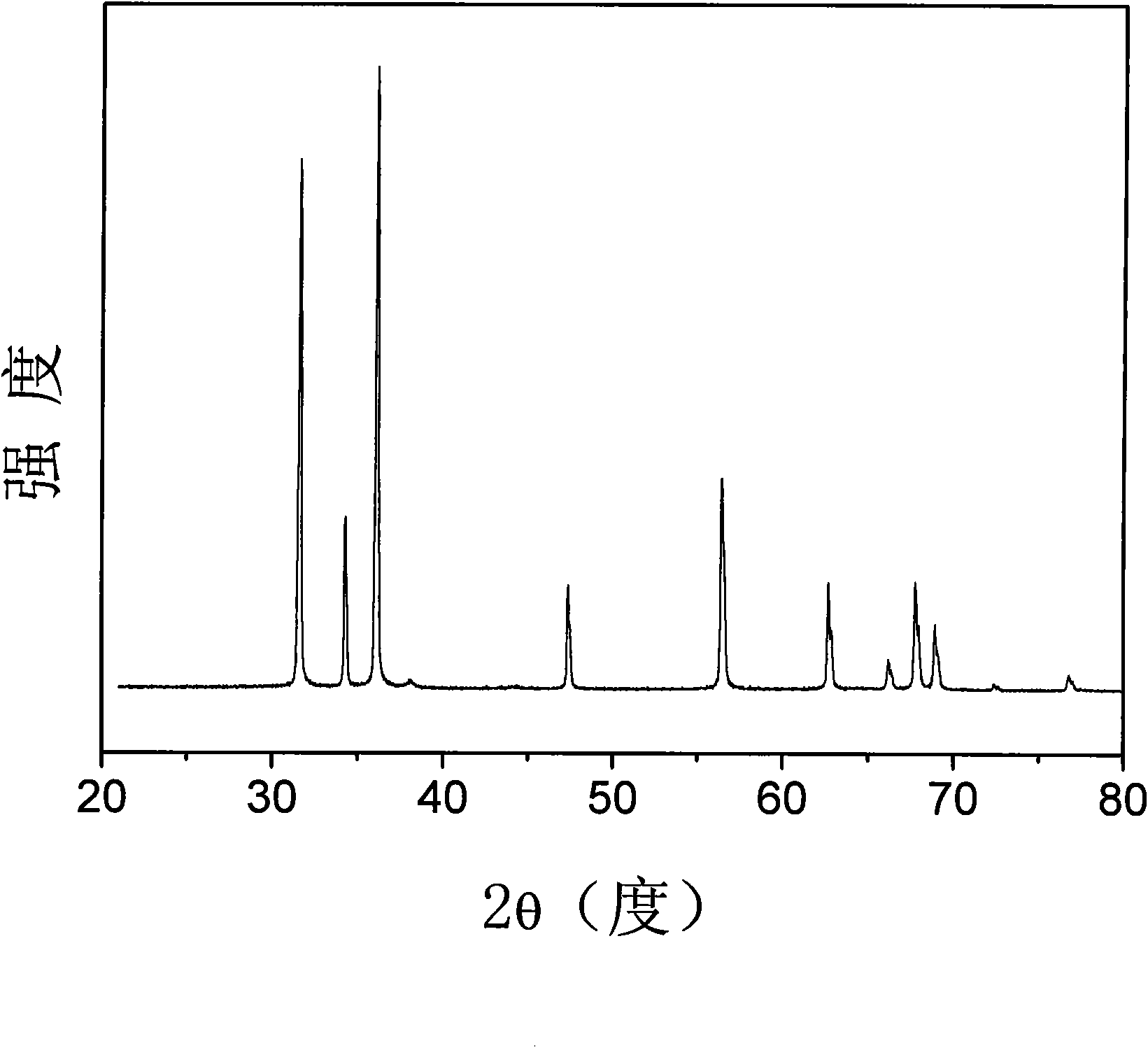

Image

Examples

Embodiment 1

[0014] Embodiment 1: First, the zinc salt solution and the hexamethylenetetramine solution are uniformly stirred, and the ratio of the zinc salt solution and the hexamethylenetetramine solution substance amount is 1:4, and the concentration is 0.05mol / L×0.2 L of zinc nitrate or zinc acetate solution and hexamethylenetetramine solution with a concentration of 0.1mol / L×0.4L are evenly stirred to form mixed solution A, and then the gold salt solution and mixed solution A are evenly stirred, and the gold salt The ratio of the amount of the solution to the zinc salt solution is 1:1000, that is, the gold chloride solution with a concentration of 0.00005mol / L×0.2L is added to the mixed solution A and stirred evenly to make it a mixed solution B, and then the mixed solution B Move to the reaction kettle that reaction temperature is 80~180 ℃ and react 2~24 hours, can choose reaction temperature to be 105~120 ℃, and reaction time is 4~12 hours, preferably reaction temperature is 120 ℃, a...

Embodiment 2

[0015] Embodiment 2: First, the zinc salt solution and the hexamethylenetetramine solution are evenly stirred, and the ratio of the zinc salt solution and the hexamethylenetetramine solution substance amount is 1: 2, and the concentration is 0.05mol / L×0.2 L of zinc nitrate or zinc acetate solution and hexamethylenetetramine solution with a concentration of 0.05mol / L×0.4L are evenly stirred to form mixed solution A, and then the gold salt solution and mixed solution A are evenly stirred, and the gold salt The ratio of the amount of the solution to the zinc salt solution is 1:500, that is, the gold chloride solution with a concentration of 0.0001mol / L×0.2L is added to the mixed solution A and stirred evenly to make it a mixed solution B, and then the mixed solution B Move to the reaction kettle that reaction temperature is 80~180 ℃ and react 2~24 hours, can choose reaction temperature to be 105~120 ℃, and reaction time is 4~12 hours, preferably reaction temperature is 120 ℃, and ...

Embodiment 3

[0016] Embodiment 3: first the zinc salt solution and the hexamethylenetetramine solution are uniformly stirred, the ratio of the amount of the zinc salt solution and the hexamethylenetetramine solution is 1:1, and the concentration is 0.05mol / L×0.2 L of zinc nitrate or zinc acetate solution and hexamethylenetetramine solution with a concentration of 0.025mol / L×0.4L are evenly stirred to form mixed solution A, and then the gold salt solution and mixed solution A are evenly stirred, and the gold salt The ratio of the amount of the solution to the zinc salt solution is 1:100, that is, the gold chloride solution with a concentration of 0.0005mol / L×0.2L is added to the mixed solution A and stirred evenly to make it a mixed solution B, and then the mixed solution B Move to the reaction kettle that reaction temperature is 80~180 ℃ and react 2~24 hours, can choose reaction temperature to be 105~120 ℃, and reaction time is 4~12 hours, preferably reaction temperature is 120 ℃, and react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com