Novel nano ferrite adsorption desulfurization catalyst and preparation method thereof

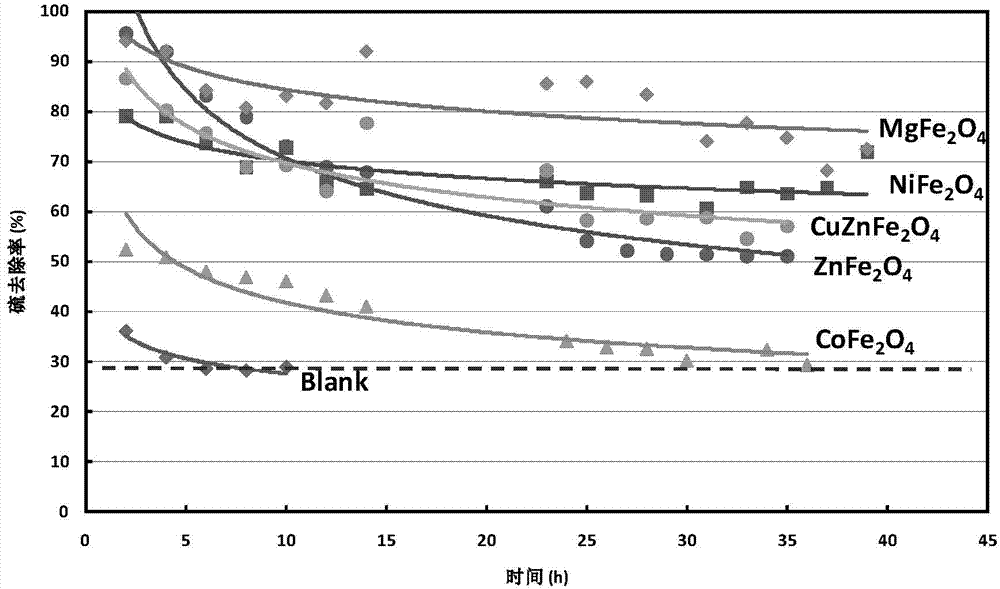

A nano-ferrite, adsorption desulfurization technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of heavy oil desulfurization effect is not obvious, The catalyst preparation process is cumbersome, the sulfur capacity is small, etc., to achieve the effect of simple and easy preparation process, mild conditions, and high desulfurization selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

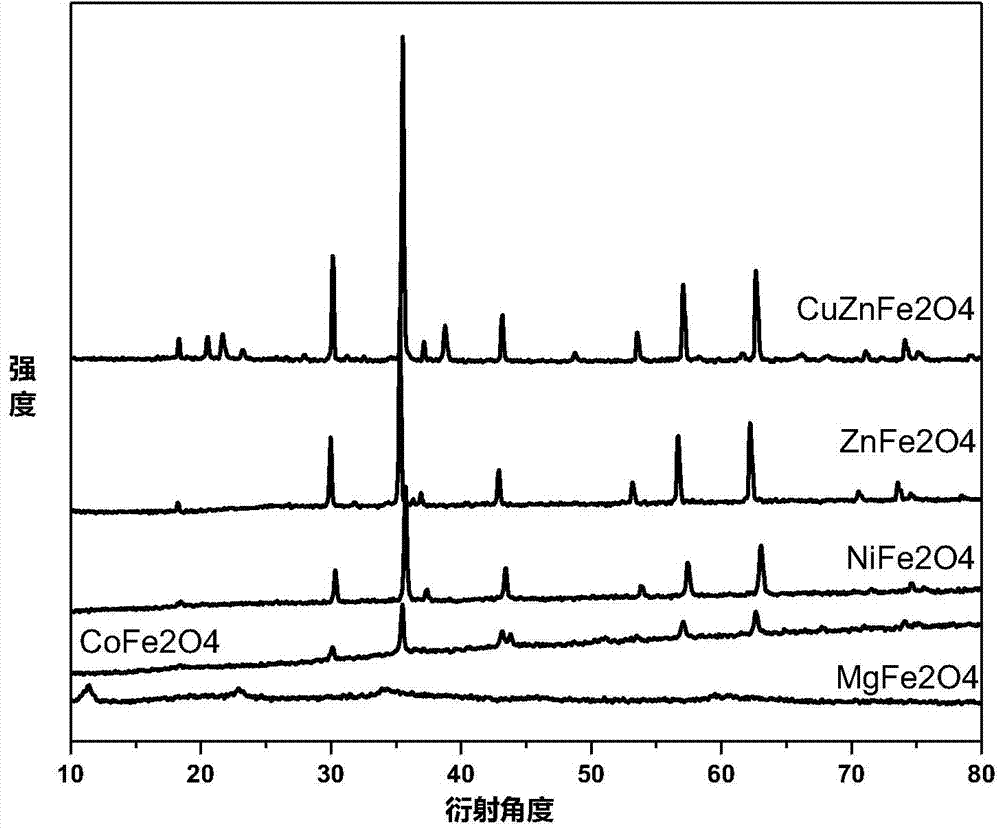

[0020] Embodiment 1: nanometer zinc ferrite (ZnFe 2 o 4 ) preparation of adsorption desulfurization catalyst

[0021] Dissolve 33mmol of zinc nitric acid, 67mmol of iron nitric acid and 200mmol of urea in 1665mmol of trace water, wherein the molar ratio of urea, metal nitrate, and water is 2:1:16.65. The solution decomposes for 15 minutes after being rapidly heated in a microwave oven with a power of 800W. During the reaction process, a large amount of flammable gas is produced, and a large amount of heat is released at the same time, so that the reactant will burn by itself after reaching the spontaneous ignition point. After the reaction is completed, the obtained solid material is nano-zinc ferrite (ZnFe 2 o 4 ) adsorption desulfurization catalyst. By replacing urea with one of fuel polyethylene glycol, sorbitol and glycine, nano-zinc ferrite (ZnFeO) with different particle sizes can also be prepared. 2 o 4 ) adsorption desulfurization catalyst.

Embodiment 2

[0022] Embodiment 2: nano nickel ferrite (NiFe 2 o 4 ) preparation of adsorption desulfurization catalyst

[0023] Dissolve 33mmol of nickel nitric acid, 67mmol of iron nitric acid and 50mmol of glycine in 1665mmol of trace water, wherein the molar ratio of glycine, metal nitrate, and water is 0.5:1:16.65. The solution decomposes for 30 minutes after being rapidly heated in a microwave oven with a power of 1200W. During the reaction process, a large amount of flammable gas is produced, and a large amount of heat is released at the same time, so that the reactant will burn by itself after reaching the spontaneous ignition point. After the reaction is completed, the obtained solid material is the nano-nickel ferrite adsorption desulfurization catalyst.

Embodiment 3

[0024] Embodiment 3: Nano magnesium ferrite (MgFe 2 o 4 ) preparation of adsorption desulfurization catalyst

[0025] Dissolve 33mmol of magnesium nitric acid, 67mmol of ferric nitric acid and 170mmol of polyethylene glycol in 1665mmol of trace water, wherein the molar ratio of polyethylene glycol, metal nitrate, and water is 1.7:1:16.65. The solution decomposes for 10 minutes after being rapidly heated in a microwave oven with a power of 400W. During the reaction process, a large amount of flammable gas is produced, and a large amount of heat is released at the same time, so that the reactant will burn by itself after reaching the spontaneous ignition point. After the reaction is completed, the obtained solid material is nano-magnesium ferrite (MgFe 2 o 4 ) adsorption desulfurization catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com