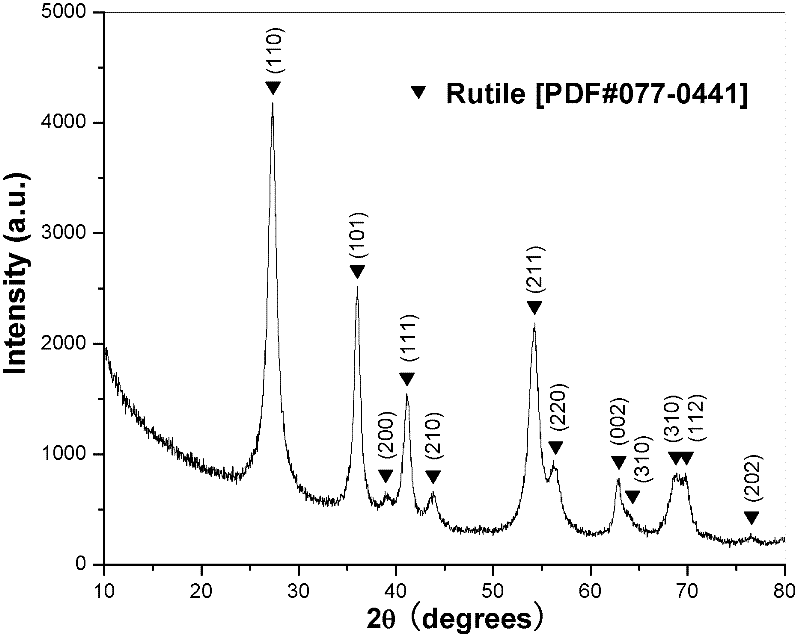

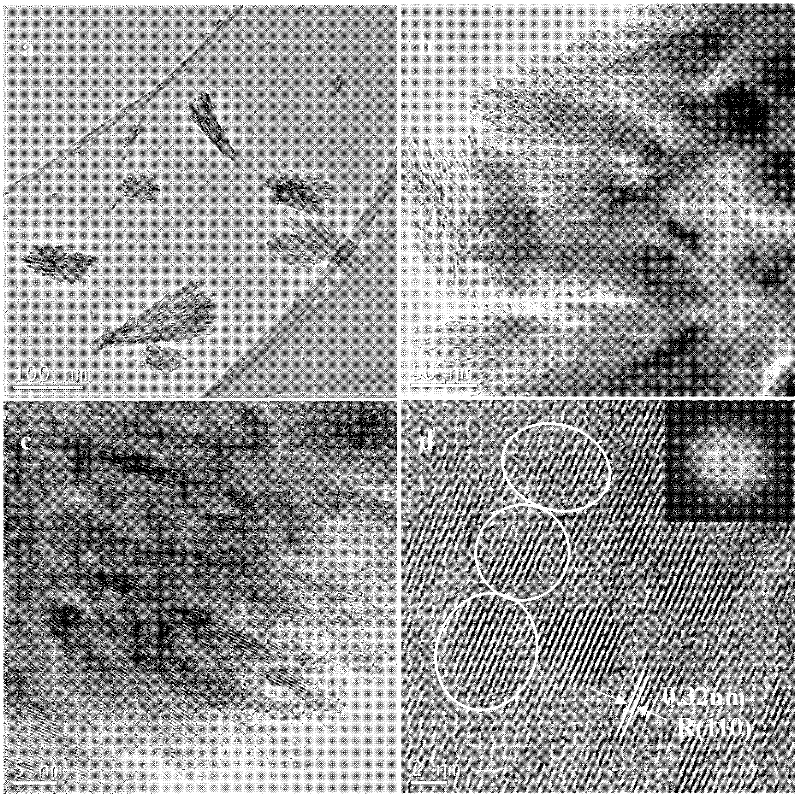

Sunlight-induced method for preparing fasciculate rutile titanium dioxide

A technology of rutile type and titanium dioxide, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems that pure rutile has not been reported, and achieve the effect of high purity, simple preparation process and low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Fix a three-neck bottle with a capacity of 500mL in an ice-water bath, measure pure water (H 2 (2) 200mL packs in the there-necked bottle; On the middle port of the there-necked bottle, condenser is installed, utilizes running water to condense; On a side port of the there-necked bottle, a thermometer is installed to monitor and control the temperature of the reaction system; Get commercially available titanium tetrachloride ( TiCl 4 ) 100mL into a dry dropping funnel, and the dropping funnel is installed on the other side port of the there-necked flask; under the conditions of magnetic stirring and ice-water bath cooling, open the switch of the dropping funnel, and slowly dissolve the titanium tetrachloride solution Add dropwise into pure water, the dropping speed is controlled at 4mL / min, the stirring speed is controlled at 800 rpm, and the temperature of the ice-water bath is controlled at 0-5°C during the whole dropping process; with the addition of titanium tet...

Embodiment 2

[0042] (1) adopt the device equipment and operating steps of step (1) in embodiment 1, prepare TiCl by the same method4 The sol was aged at room temperature for 48 hours.

[0043] (2) Measure 48mL of pure water into a 100mL colorless transparent glass bottle, and then add aged TiCl 4 sol 8mL, fully stirred, the solution is colorless; put it outdoors in a spacious place with sufficient sunlight, the outdoor temperature is 10-20°C, and the relative humidity is 50-60%. After 5 days, a small amount of white particles begin to appear. A large amount of white precipitate appeared in the day;

[0044] (3) The resulting precipitate was filtered, washed with pure water, and dried in an oven at 70° C. to obtain 0.426 g of beam-shaped rutile-type titanium dioxide powder.

Embodiment 3

[0046] (1) adopt the device equipment and operating steps of step (1) in embodiment 1, prepare TiCl by the same method 4 The sol was aged at room temperature for 48 hours.

[0047] (2) Measure 48mL of pure water into a 100mL colorless transparent glass bottle, and then add aged TiCl 4 sol 4mL, fully stirred, the solution is colorless; put it outdoors in a spacious place with sufficient sunlight, the outdoor temperature is 10-20°C, and the relative humidity is 50-60%. After 7 days, a small amount of white particles begin to appear. A large amount of white precipitate appeared in the day;

[0048] (3) The obtained precipitate was filtered, washed with pure water, and dried in an oven at 70°C to obtain 0.137 g of beam-shaped rutile-type titanium dioxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com