Catalyst of metallic oxide for preparing nanowall nano carbon pipe and preparation process thereof

A technology of carbon nanotubes and oxides, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Problems such as low yield, low utilization rate and low catalytic efficiency can achieve the effect of high degree of graphitization, strong activity and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Molybdenum oxide was added to the deionized aqueous solution, heated and stirred at 80° C. for 0.5 hour, until the reaction was completely dissolved. Dissolve iron nitrate nonahydrate and magnesium ethylate in the molybdenum-containing solution respectively, stir for 1 hour, and mix uniformly. The molar ratio of iron:molybdenum:magnesium in the solution is 2:0.5:15. Then the above mixed solution was frozen at -60°C, and then the solid formed by freezing was subjected to a primary drying treatment at -30°C for 36 hours to remove crystal water in the freeze-dried solid, and then a secondary drying treatment was performed at 30°C for 6 hours. The above freeze-dried catalyst can be used for the preparation of single-walled carbon nanometer tubes.

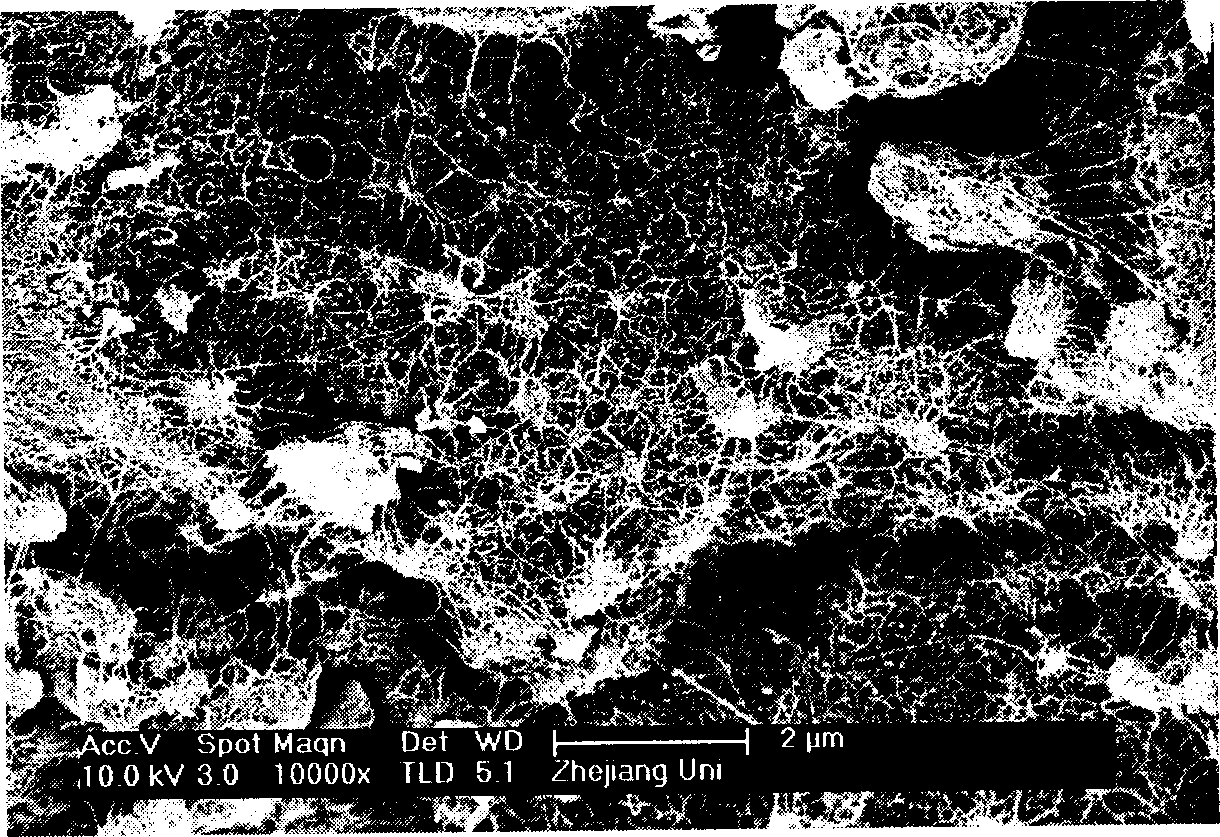

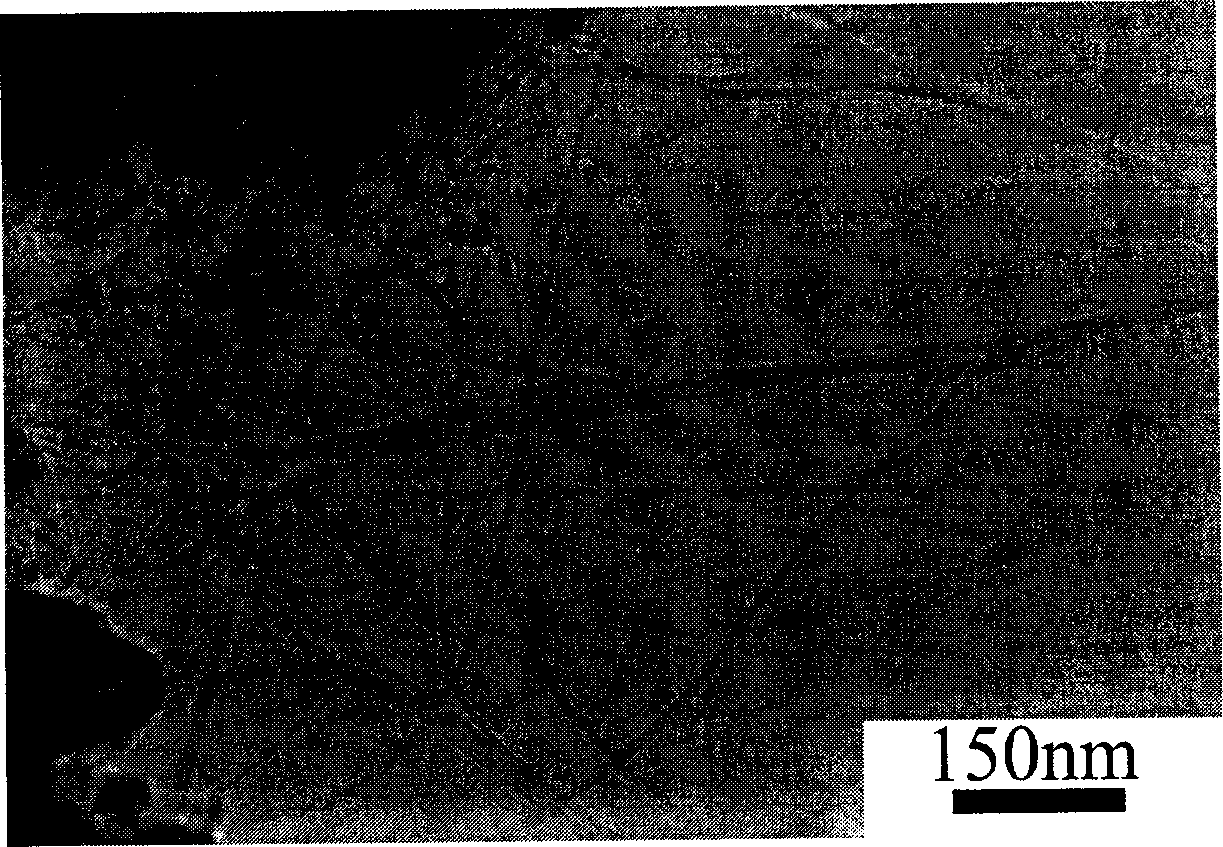

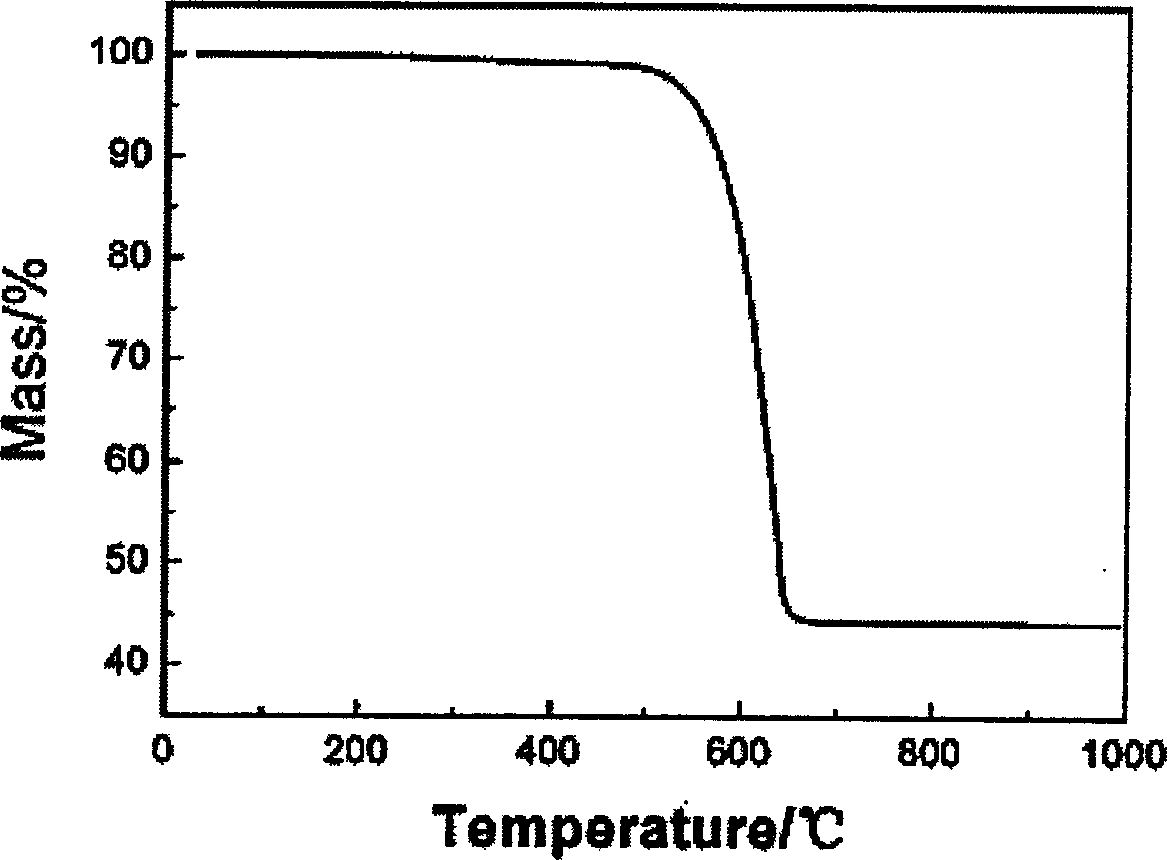

[0015] The preparation of single-wall carbon nanotubes is carried out in a fixed-bed gas continuous flow reactor. Put 0.112 grams of catalyst into the constant temperature zone in the middle of the furnace, feed methane with a f...

Embodiment 2

[0017] Ammonium molybdate was added to the deionized aqueous solution, heated and stirred at 80°C for 0.5 hours until the reaction was completely dissolved. Dissolve ferric nitrate nonahydrate and magnesium ethylate in the molybdenum-containing solution respectively, stir for 1 hour, and mix uniformly. The molar ratio of iron:molybdenum:magnesium in the solution is 1:0.1:15. Freeze, and then perform a 24-hour primary drying process on the frozen solid at -30°C to remove crystal water in the freeze-dried solid, and then perform a secondary drying process at 40°C for 6 hours. The above freeze-dried catalyst can be used for the preparation of single-walled carbon nanometer tubes.

[0018] The carbon tubes were prepared in a fixed-bed gas continuous flow reaction furnace. Put 0.103 grams of catalyst into the constant temperature zone in the middle of the furnace, feed methane with a flow rate of 75 sccm and hydrogen with a flow rate of 200 sccm, control the reaction temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com