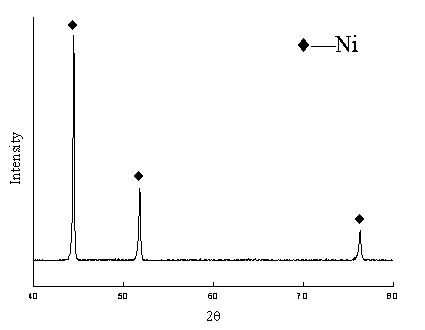

Method for preparing superfine simple-substance nickel powder

A technology of elemental nickel and preparation steps, applied in the field of preparation of ultrafine elemental nickel powder, can solve the problems of bad crystal form of nickel powder, long reaction time, cumbersome operation, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The operation steps of this preparation method are:

[0020] First, add nickel oxide or nickel salt into the reactor, discharge the air in the reactor, then add a solvent medium into the reactor, and heat the reactor so that the temperature reaches 100-350°C and the pressure is 0.1-30MPa. And keep it in this state for 0.05 ~ 2h; then keep the temperature constant, release the pressure in the reactor to 0 ~ 2 MPa within 0.05 ~ 1.5 h, cool the reactor to room temperature, take out the solid in the reactor Powder, ultrafine elemental nickel powder can be obtained after ultrasonic dispersion, washing and vacuum drying. The raw material is one or more mixtures of nickel oxide, nickel acetate, nickel nitrate, nickel carbonate, and basic nickel carbonate; the solvent medium includes one or two mixtures of methanol and ethanol; the reaction temperature is controlled at 100-350 ℃; the reaction pressure is controlled at 0.1-30MPa, the reaction time is controlled at 0.05-2h; the ...

Embodiment 1

[0022] Take 6.0g of nickel acetate and place it in a reactor with a volume of 0.15L, seal the reactor and then evacuate it to 0.01MPa, add 100g of methanol, heat the reactor to 180°C, the pressure is 8.4MPa, and then react under these conditions After 0.6h, the pressure at the end of the reaction was reduced to 0.1 MPa. After cooling to room temperature, the product in the reactor was taken out, ultrasonically vibrated for 5 minutes, washed three times with deionized water and anhydrous methanol, and vacuum-dried at 60°C. The obtained product was 1.4g.

Embodiment 2

[0024] Add nickel nitrate hydrate (4.0g) into the pressure-resistant reactor, and take out the air in the reactor. After adding 60g of ethanol, raise the temperature of the reactor to 235°C and the pressure to 12.0 MPa, and keep it under this condition for 1h. Then the pressure was lowered to 1.3 MPa within 0.5 h. After cooling down, the product in the reactor was taken out. After ultrasonic dispersion, it was washed several times with deionized water and anhydrous methanol successively, and dried in vacuum. The obtained product was 0.75 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com