Perovskite nanoparticle catalyst and preparation method and application thereof

A nanoparticle and catalyst technology, which is applied in the field of perovskite nanoparticle catalyst and its preparation, can solve the problems of precursor limitation, lack of understanding of the formation mechanism of perovskite material crystal structure, etc., and achieve the maintenance of lattice structure and repeatable preparation , The effect of shortening the heat treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

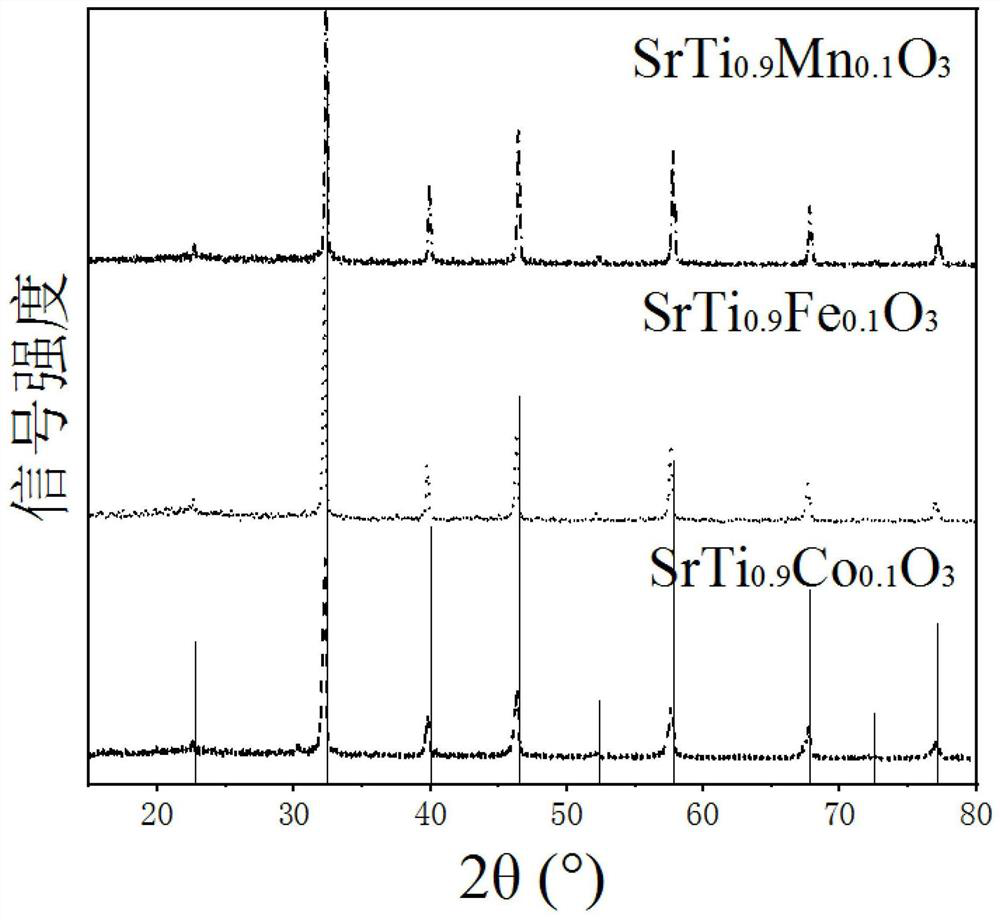

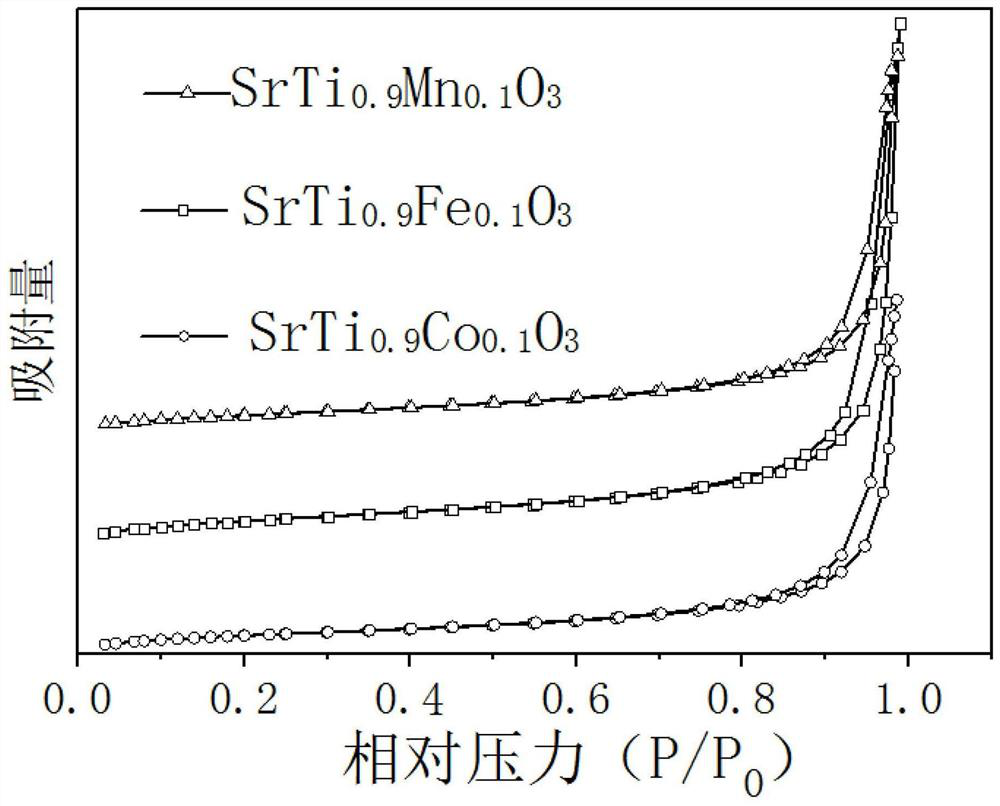

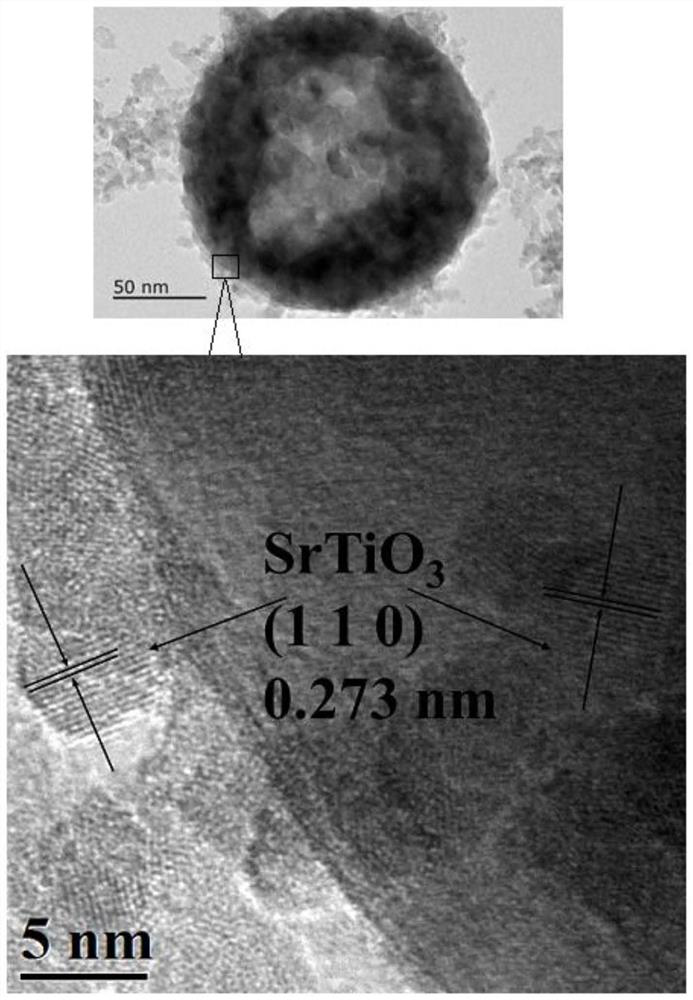

Embodiment 1

[0047] 1. Add 3.11 g of strontium acetate to 50 mL of acetic acid solution, stir vigorously for 5 minutes, and perform ultrasonic treatment for 10 minutes, then continue stirring until the solid strontium acetate is completely dissolved in the acetic acid solution to form a clear and transparent solution.

[0048] 2. Add the molecular sieve into the acetic acid solution to remove the water in the solution, and after standing for 10 minutes, the molecular sieve can be filtered out.

[0049] 3. Dissolve 4.59g of n-butyl titanate in 50mL of ethanol and stir, then add 0.518g of metal precursor of cobalt 2-ethylhexanoate, and stir vigorously.

[0050] 4. The precursor solution obtained by mixing the acetic acid solution and the ethanol solution was vigorously stirred until the precursor solution was uniform and clear, and the concentration of the solution was 0.15 mol / L.

[0051] 5. Atomize the prepared precursor solution through the injection pump jet flow, and keep the feed flow ...

Embodiment 2

[0054] 1. Add 3.11 g of strontium acetate to 50 mL of acetic acid solution, stir vigorously for 5 minutes, and perform ultrasonic treatment for 10 minutes, then continue stirring until the solid strontium acetate is completely dissolved in the acetic acid solution to form a clear and transparent solution.

[0055] 2. Add the molecular sieve into the acetic acid solution to remove the water in the solution, and after standing for 10 minutes, the molecular sieve can be filtered out.

[0056] 3. Dissolve 4.59 g of n-butyl titanate in 50 mL of ethanol and stir, then add 0.747 g of metal precursor of iron naphtenate and stir vigorously.

[0057] 4. The precursor solution obtained by mixing the acetic acid solution and the ethanol solution was vigorously stirred until the precursor solution was uniform and clear, and the concentration of the solution was 0.15 mol / L.

[0058] 5. Atomize the prepared precursor solution through the injection pump jet flow, and keep the feed flow rate o...

Embodiment 3

[0061] 1. Add 3.11 g of strontium acetate to 50 mL of acetic acid solution, stir vigorously for 5 minutes, and perform ultrasonic treatment for 10 minutes, then continue stirring until the solid strontium acetate is completely dissolved in the acetic acid solution to form a clear and transparent solution.

[0062] 2. Add the molecular sieve into the acetic acid solution to remove the water in the solution, and after standing for 10 minutes, the molecular sieve can be filtered out.

[0063] 3. 4.59 g of n-butyl titanate was dissolved in 50 mL of ethanol and stirred, then 1.280 g of metal precursor of manganese 2-ethylhexanoate was added and vigorously stirred.

[0064] 4. The precursor solution obtained by mixing the acetic acid solution and the ethanol solution was vigorously stirred until the precursor solution was uniform and clear, and the concentration of the solution was 0.15 mol / L.

[0065] 5. Atomize the prepared precursor solution through the injection pump jet flow, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com