Dihydrate gypsum based fireproof coating material

A technology of fire retardant coating and dihydrate gypsum, applied in the field of comprehensive utilization of industrial waste resources and fire retardant coating, can solve the problems of high resource consumption, empty drum, energy loss, etc., and achieve good fire resistance, cost reduction and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

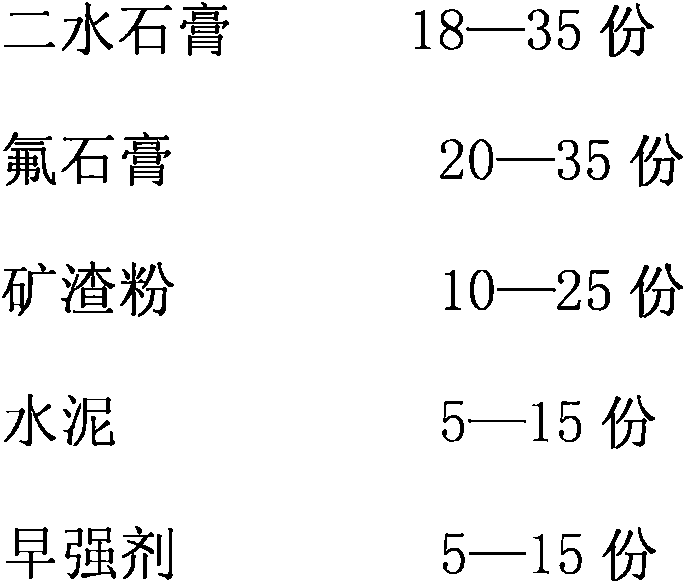

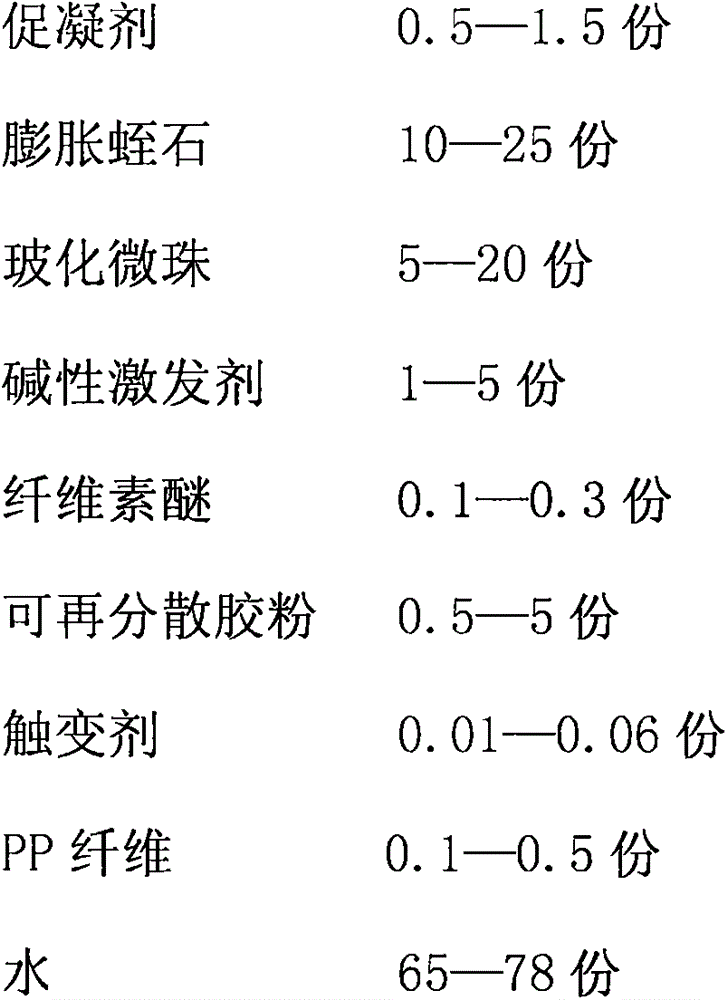

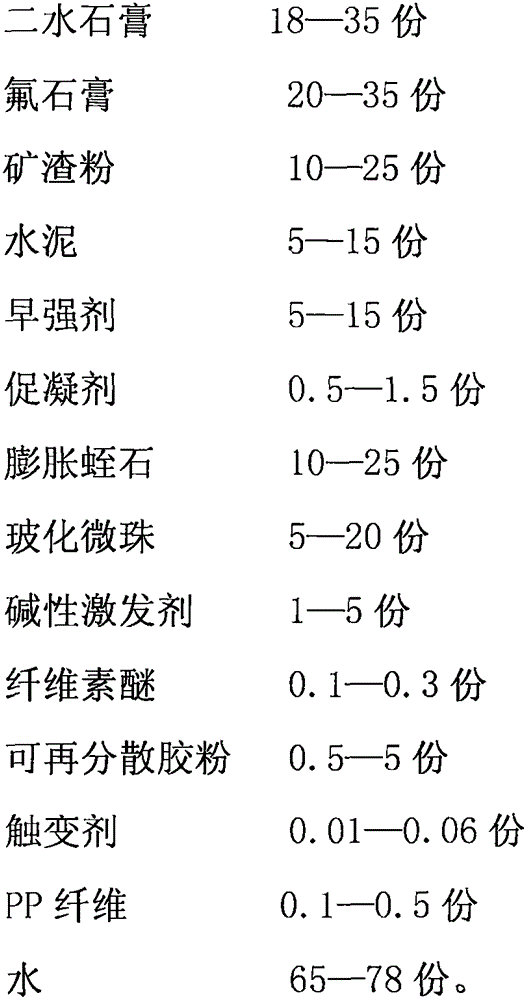

Method used

Image

Examples

Embodiment 1

[0024] By weight, weigh 25 parts of dihydrate gypsum, 26 parts of fluorogypsum, 18 parts of slag powder, 6 parts of cement, 6 parts of early strength agent, 1.1 parts of coagulation accelerator, 2 parts of alkaline activator, and 0.3 parts of cellulose ether , 3 parts of redispersible rubber powder, 0.05 part of thixotropic agent, and 0.2 part of PP fiber are put into the dry powder mixer, mixed and stirred for 3 minutes to obtain a uniformly mixed mixture, and then the stirred mixture is put into the mixer, Add 70 parts of water, mix and stir for 3 minutes, then add 10 parts of expanded vermiculite and 15 parts of vitrified microbeads, and stir for 2 minutes to obtain a dihydrate gypsum-based fireproof coating.

[0025] The dry density of the obtained dihydrate gypsum-based fireproof coating is 498kg / m 3 , the flexural strength is 0.58MPa, the compressive strength is 1.6MPa, the softening coefficient is 0.78, and the combustion performance is A2 level.

Embodiment 2

[0027] By weight, weigh 19 parts of dihydrate gypsum, 23 parts of fluorogypsum, 15 parts of slag powder, 8 parts of cement, 10 parts of early strength agent, 1 part of coagulation accelerator, 2.5 parts of alkaline activator, and 0.2 parts of cellulose ether , 3 parts of redispersible rubber powder, 0.06 part of thixotropic agent, and 0.3 part of PP fiber are put into the dry powder mixer, mixed and stirred for 3 minutes to obtain a uniformly mixed mixture, and then the stirred mixture is put into the mixer, Add 75 parts of water, mix and stir for 3 minutes, then add 19 parts of expanded vermiculite and 6 parts of vitrified microbeads, and stir for 2 minutes to obtain a dihydrate gypsum-based fireproof coating.

[0028] The dry density of the obtained dihydrate gypsum-based fireproof coating is 451kg / m 3 , the flexural strength is 0.45MPa, the compressive strength is 1.2MPa, the softening coefficient is 0.72, and the combustion performance is A2 level.

Embodiment 3

[0030] By weight, weigh 21 parts of dihydrate gypsum, 26 parts of fluorogypsum, 18 parts of slag powder, 10 parts of cement, 6 parts of early strength agent, 0.8 part of coagulation accelerator, 2 parts of alkaline activator, and 0.25 part of cellulose ether , 2.5 parts of redispersible rubber powder, 0.05 parts of thixotropic agent, and 0.3 parts of PP fiber are put into the dry powder mixer, mixed and stirred for 3 minutes to obtain a uniformly mixed mixture, and then the stirred mixture is put into the mixer, Add 71 parts of water, mix and stir for 3 minutes, then add 12 parts of expanded vermiculite and 13 parts of vitrified microbeads, and stir for 2 minutes to obtain a dihydrate gypsum-based fireproof coating.

[0031] The dry density of the obtained dihydrate gypsum-based fireproof coating is 468kg / m 3 , the flexural strength is 0.66MPa, the compressive strength is 1.18MPa, the softening coefficient is 0.87, and the combustion performance is A2 level.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com