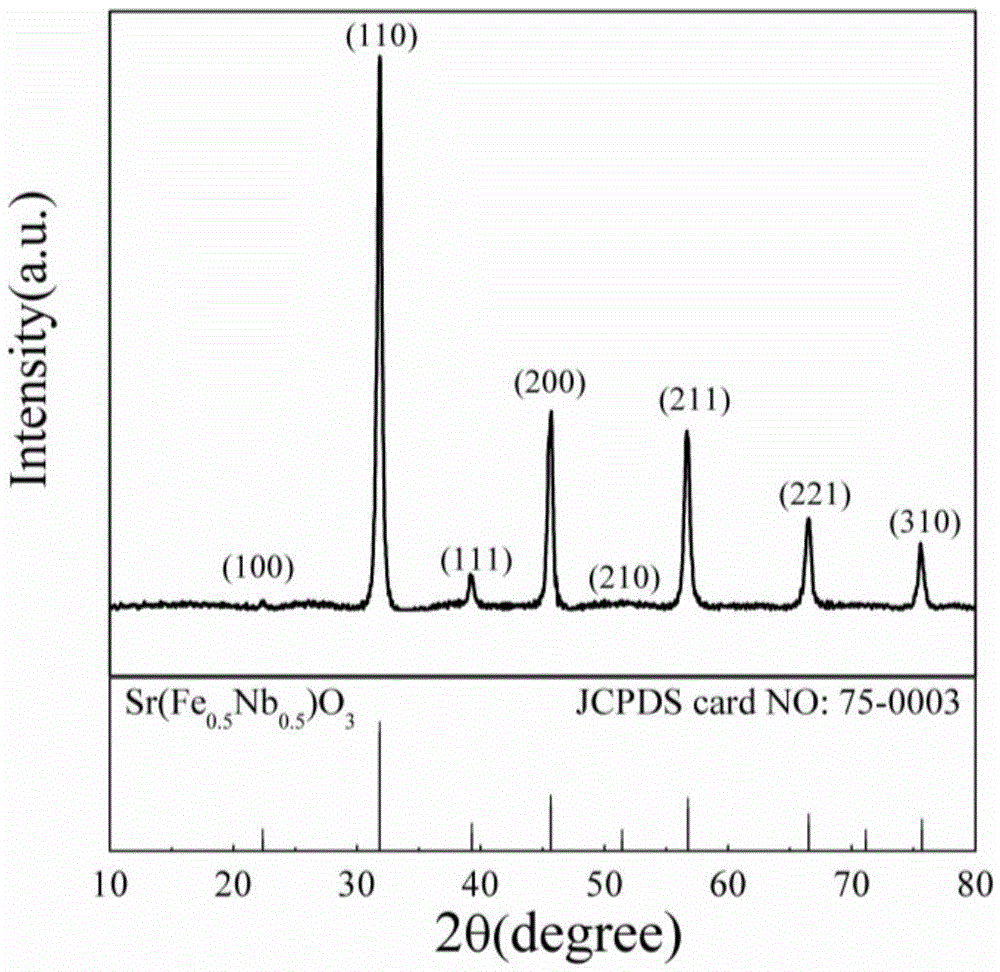

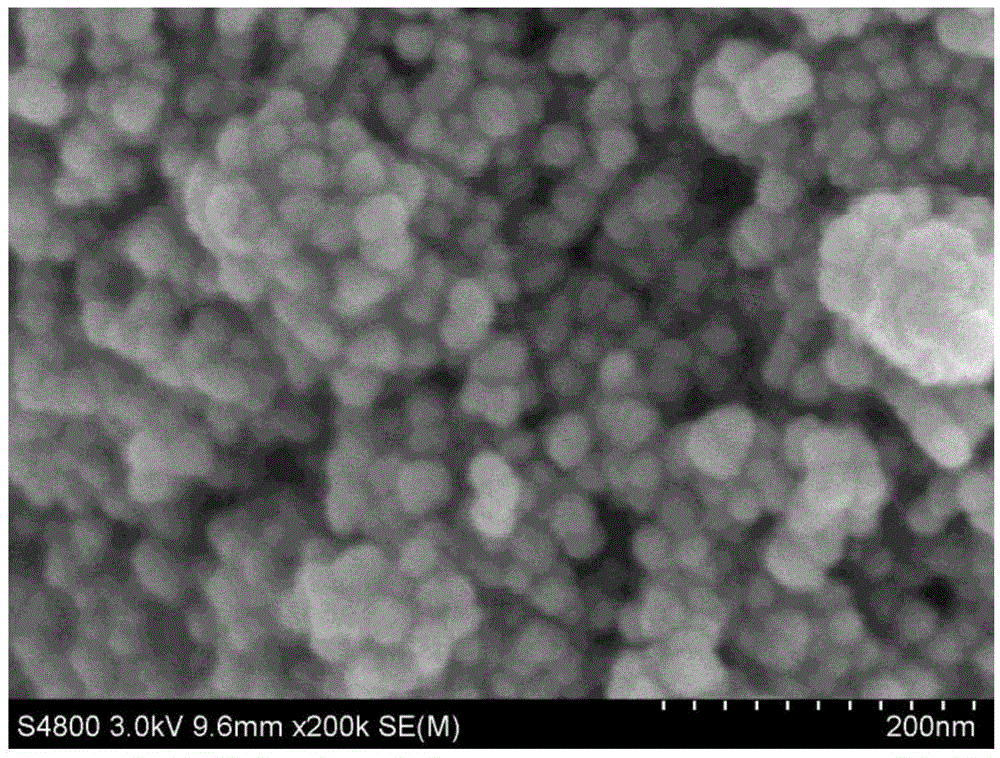

Method for preparing nano Sr(Fe0.5Nb0.5)O3 powder by microwave-hydrothermal method

A microwave hydrothermal method, powder technology, applied in the direction of nanotechnology, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of limited ceramic performance, low sinterability, high calcination temperature, etc., to achieve the improvement of large particle size, Improved dielectric properties and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0034] A kind of microwave hydrothermal method of the present invention prepares nanometer Sr (Fe 0.5 Nb 0.5 )O 3 The powder method comprises the following steps, (1) preparing a dilute hydrochloric acid solution with a concentration of 1 mol / L and a NaOH solution with a concentration of 5 mol / L in advance for subsequent use. According to Sr(Fe 0.5 Nb 0.5 )O 3 The stoichiometric ratio of 2:1:1 accurately weighs Ba(NO 3 )2 , Fe(NO 3 ) 3 9H 2 O and NbCl 5 .

[0035] (2) Quickly weigh NbCl 5 , was dissolved in dilute hydrochloric acid prepared in advance, sealed with plastic wrap, and placed in a magnetic stirrer to stir for 10 h.

[0036] (3) Sr(NO 3 ) 2 Dissolve in deionized water, add Fe(NO 3 ) 3 9H 2 O, and add 8 drops of 30% hydrogen peroxide dropwise. During this process, the mixed solution A will be continuously stirred. When mixing evenly, the stirring time is 1 h.

[0037] (4) Add NbCl dropwise to the mixed solution A under stirring 5 hydrochloric acid ...

example 2

[0041] A kind of microwave hydrothermal method of the present invention prepares nanometer Sr (Fe 0.5 Nb 0.5 )O 3 The method for the powder comprises the following steps, (1) preparing a dilute hydrochloric acid solution with a concentration of 2 mol / L and a NaOH solution with a concentration of 8 mol / L in advance for subsequent use. According to Sr(Fe 0.5 Nb 0.5 )O 3 The stoichiometric ratio of 2:1:1 accurately weighs Sr(NO 3 ) 2 , Fe(NO 3 ) 3 9H 2 O and NbCl 5 .

[0042] (2) Quickly weigh NbCl 5 , was dissolved in dilute hydrochloric acid prepared in advance, sealed with plastic wrap, and placed in a magnetic stirrer to stir for 12 hours.

[0043] (3) Sr(NO 3 ) 2 Dissolve in deionized water, add Fe(NO 3 ) 3 9H 2 O, and add 10 drops of 30% hydrogen peroxide dropwise. During this process, the mixed solution A should be continuously stirred. When mixing evenly, the stirring time is 1.5h.

[0044] (4) Add NbCl dropwise to the mixed solution A under stirring 5 ...

example 3

[0048] A kind of microwave hydrothermal method of the present invention prepares nanometer Sr (Fe 0.5 Nb 0.5 )O 3 The method for the powder comprises the following steps, (1) preparing a dilute hydrochloric acid solution with a concentration of 3mol / L and a NaOH solution with a concentration of 10mol / L in advance for subsequent use. According to Sr(Fe 0.5 Nb 0.5 )O 3 The stoichiometric ratio of 2:1:1 accurately weighs Sr(NO 3 ) 2 , Fe(NO 3 ) 3 9H 2 O and NbCl 5 .

[0049] (2) Quickly weigh NbCl 5 , was dissolved in dilute hydrochloric acid prepared in advance, sealed with plastic wrap, and placed in a magnetic stirrer to stir for 15 hours.

[0050] (3) Sr(NO 3 ) 2 Dissolve in deionized water, add Fe(NO 3 ) 3 9H 2 O, and add 15 drops of 30% hydrogen peroxide dropwise. During this process, the mixed solution A will be continuously stirred. When mixing evenly, the stirring time is 2 hours.

[0051] (4) Add NbCl dropwise to the mixed solution A under stirring 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com