Regeneration technology of denitration catalyst

A denitration catalyst and process technology, applied in the field of denitration catalyst regeneration technology, can solve the problems of inability to accurately control the amount of active substances, unstable denitration efficiency, increase production cost, etc., and achieve the effects of strong acting force, inhibition of sintering, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

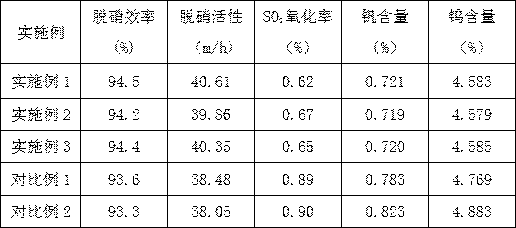

Examples

Embodiment 1

[0015] The regeneration process of the denitration catalyst includes the following specific steps:

[0016] 1) Pretreatment of the deactivated denitrification catalyst: remove the dust on the surface of the deactivated denitrification catalyst by a negative pressure vacuum cleaner, then immerse the catalyst in a deionized aqueous solution containing 0.05% lactic acid and 0.10% oxalic acid, ultrasonicate at 20HZ for 30min, take it out and store it at 120°C Dry for 90min;

[0017] 2) Implantation of active substances by atomic layer deposition method: put the catalyst treated in step 1) into the reaction chamber of the atomic layer deposition equipment, and seal the reaction chamber; vacuumize the atomic layer deposition system and introduce high-purity nitrogen gas to adjust The outlet valve of the reaction chamber makes the pressure in the chamber negative, and the deposition temperature is set at 300°C; inject the mixed precursor of vanadium oxide triisopropoxide and tungsten...

Embodiment 2

[0019] The regeneration process of the denitration catalyst includes the following specific steps:

[0020] 1) Pretreatment of the deactivated denitrification catalyst: remove the dust on the surface of the deactivated denitrification catalyst by a negative pressure vacuum cleaner, then immerse the catalyst in a deionized aqueous solution containing 0.1% lactic acid and 0.20% oxalic acid, ultrasonicate at 40HZ for 60min, take it out and store it at 150°C Dry for 30min;

[0021] 2) Implantation of active substances by atomic layer deposition method: put the catalyst treated in step 1) into the reaction chamber of the atomic layer deposition equipment, and seal the reaction chamber; vacuumize the atomic layer deposition system and introduce high-purity nitrogen gas to adjust The outlet valve of the reaction chamber keeps the pressure in the chamber at negative pressure, and the deposition temperature is set at 400°C; the mixed precursor of vanadium triisopropoxide and tungsten e...

Embodiment 3

[0023] The regeneration process of the denitration catalyst includes the following specific steps:

[0024] 1) Pretreatment of the deactivated denitrification catalyst: remove the dust on the surface of the deactivated denitrification catalyst with a negative pressure vacuum cleaner, then immerse the catalyst in a deionized aqueous solution containing 0.08% lactic acid and 0.15% oxalic acid, ultrasonicate at 28HZ for 45min, take it out and store it at 140°C Dry for 60min;

[0025] 2) Implantation of active substances by atomic layer deposition method: put the catalyst treated in step 1) into the reaction chamber of the atomic layer deposition equipment, and seal the reaction chamber; vacuumize the atomic layer deposition system and introduce high-purity nitrogen gas to adjust The outlet valve of the reaction chamber makes the pressure in the chamber negative, and the deposition temperature is set at 350°C; the mixed precursor of vanadium oxide acetylacetonate and tungsten dich...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com