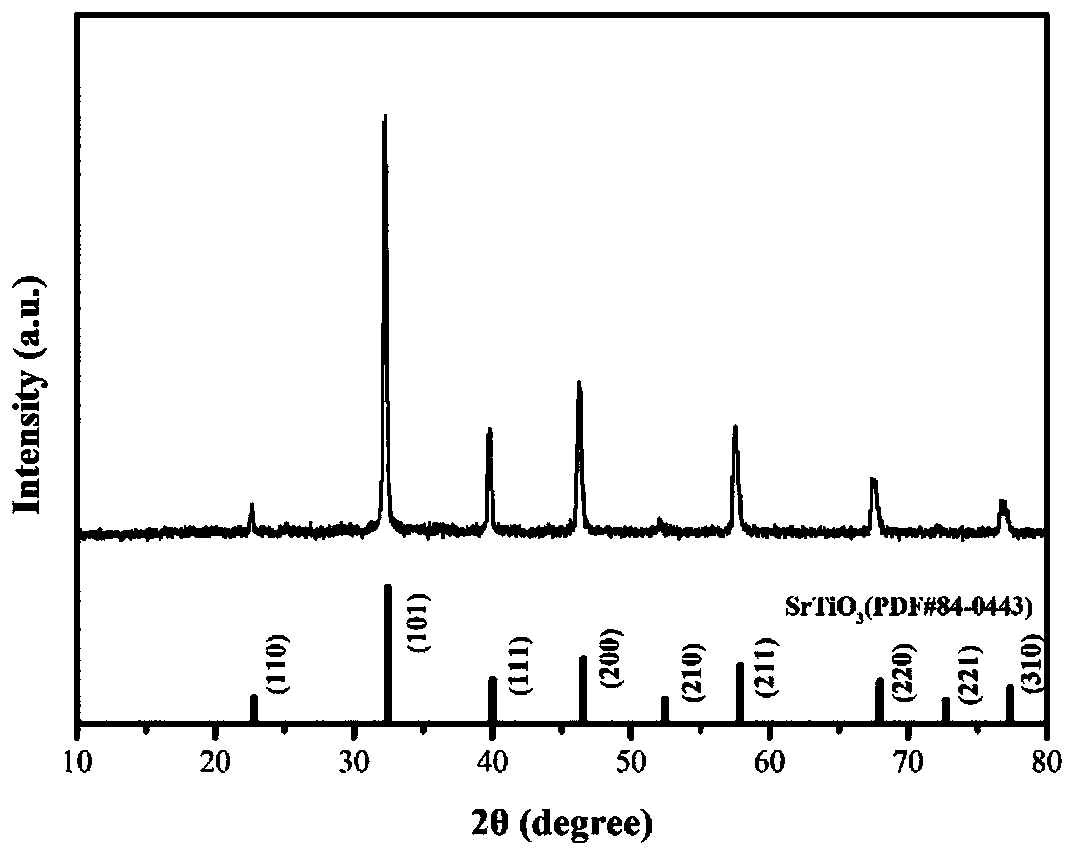

Synthesis method of mesoporous single crystal strontium titanate

A synthesis method and technology of strontium titanate, which are applied in the field of mesoporous single crystal strontium titanate materials, can solve the problems of complex process, unable to maintain mesoporous structure completely, structure collapse and the like, and achieve simple synthesis process, low synthesis and cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

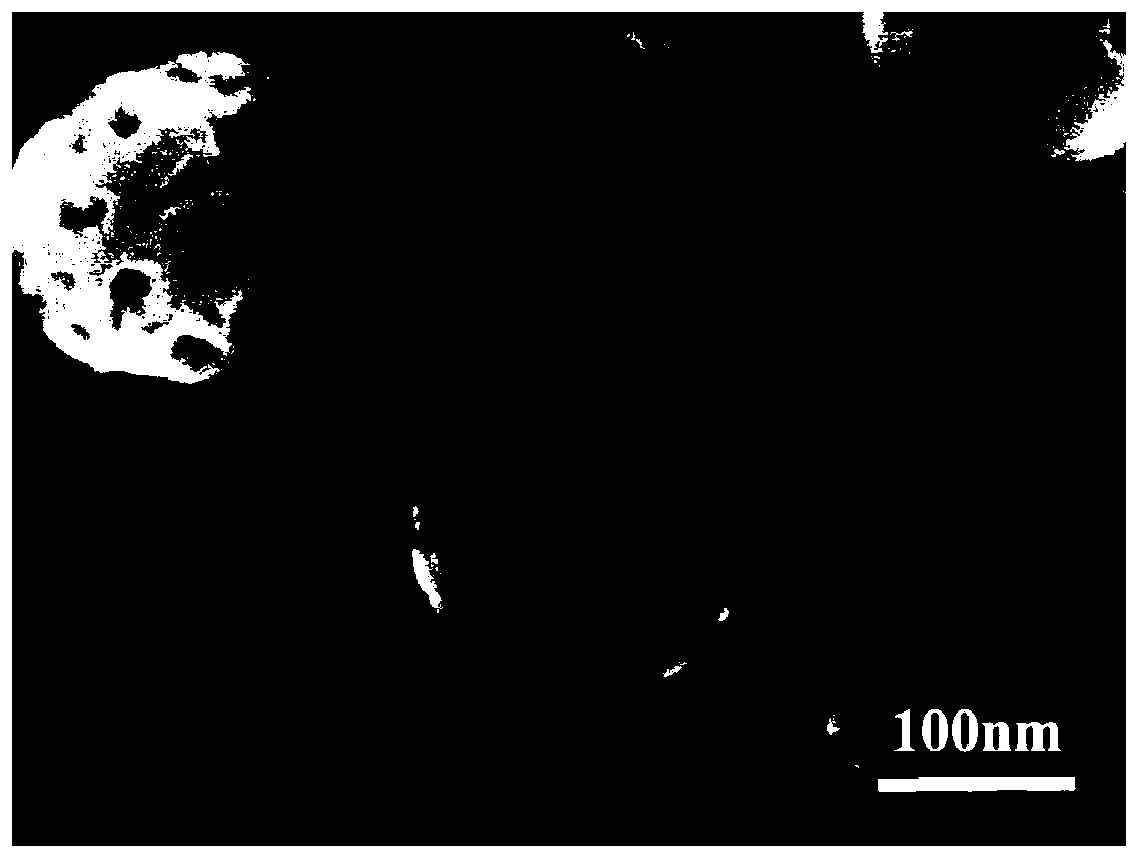

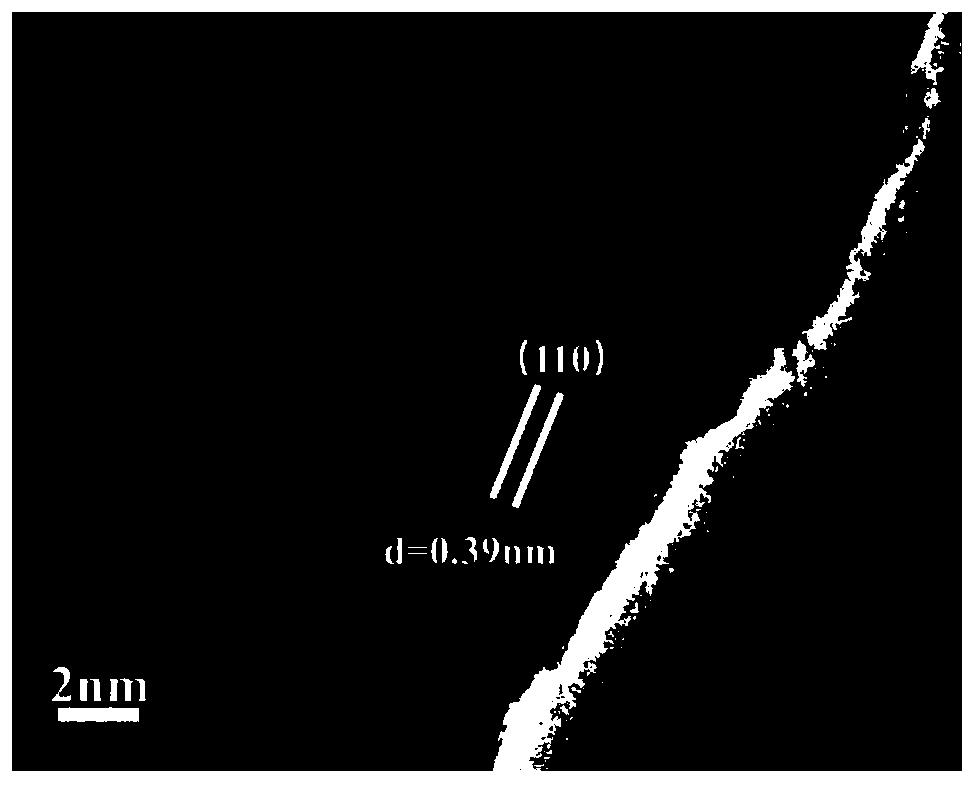

Embodiment 1

[0031] Step 1. Preparation of mesoporous single crystal strontium titanate particles:

[0032] 0.5 mL of 10wt.% TiCl 3 Titanium trichloride solution dissolved in 20-30wt.% hydrochloric acid, dissolved in 25mL of deionized water, and stirred for 6 minutes, then 1.2g of ethylene glycol was added dropwise and vigorously stirred for 8 minutes; 3.5g of lithium hydroxide was dissolved In 30mL deionized water, stir until clear and ready to use. Lithium hydroxide solution was slowly added dropwise to TiCl with stirring 3 In the solution, a white emulsion was formed, which was then vigorously stirred for 20 minutes. Add 1.0 g of strontium chloride hexahydrate to the above emulsion, stir for 10 minutes and transfer to a polytetrafluoroethylene lining, seal it in a stainless steel reactor and keep warm at 185°C for 36 hours. Then cool naturally to room temperature, centrifuge to obtain the reactant, wash with deionized water and ethanol five times respectively, and dry in an oven at 6...

Embodiment 2

[0037] 1.0 mL of 10wt.% TiCl 3 Dissolve titanium trichloride solution in 20-30wt.% hydrochloric acid, dissolve in 25mL of deionized water, and stir for 8 minutes, then add 0.9g of ethylene glycol dropwise and stir vigorously for 10 minutes; dissolve 5.0g of lithium hydroxide In 30mL deionized water, stir until clear and ready to use. Lithium hydroxide solution was slowly added dropwise to the 3 The solution was stirred continuously to form a white emulsion, and stirred vigorously for 30 minutes. Add 0.8g of strontium chloride hexahydrate into the above emulsion, stir for 10 minutes and transfer to a polytetrafluoroethylene lining, seal it in a stainless steel reactor and keep it warm at 170°C for 48 hours. Then cool naturally to room temperature, centrifuge to obtain the reactant, wash with deionized water and ethanol five times respectively, and dry in an oven at 70° C. to obtain mesoporous single crystal strontium titanate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com