Preparation method of metal cation doped modified lithium ion sieve

A technology of metal cations and lithium ions, applied in chemical instruments and methods, inorganic chemistry, manganese compounds, etc., can solve the problems of long cycle time and cumbersome preparation process steps, and achieve the advantages of reduced dissolution loss, simple preparation process and mild preparation conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

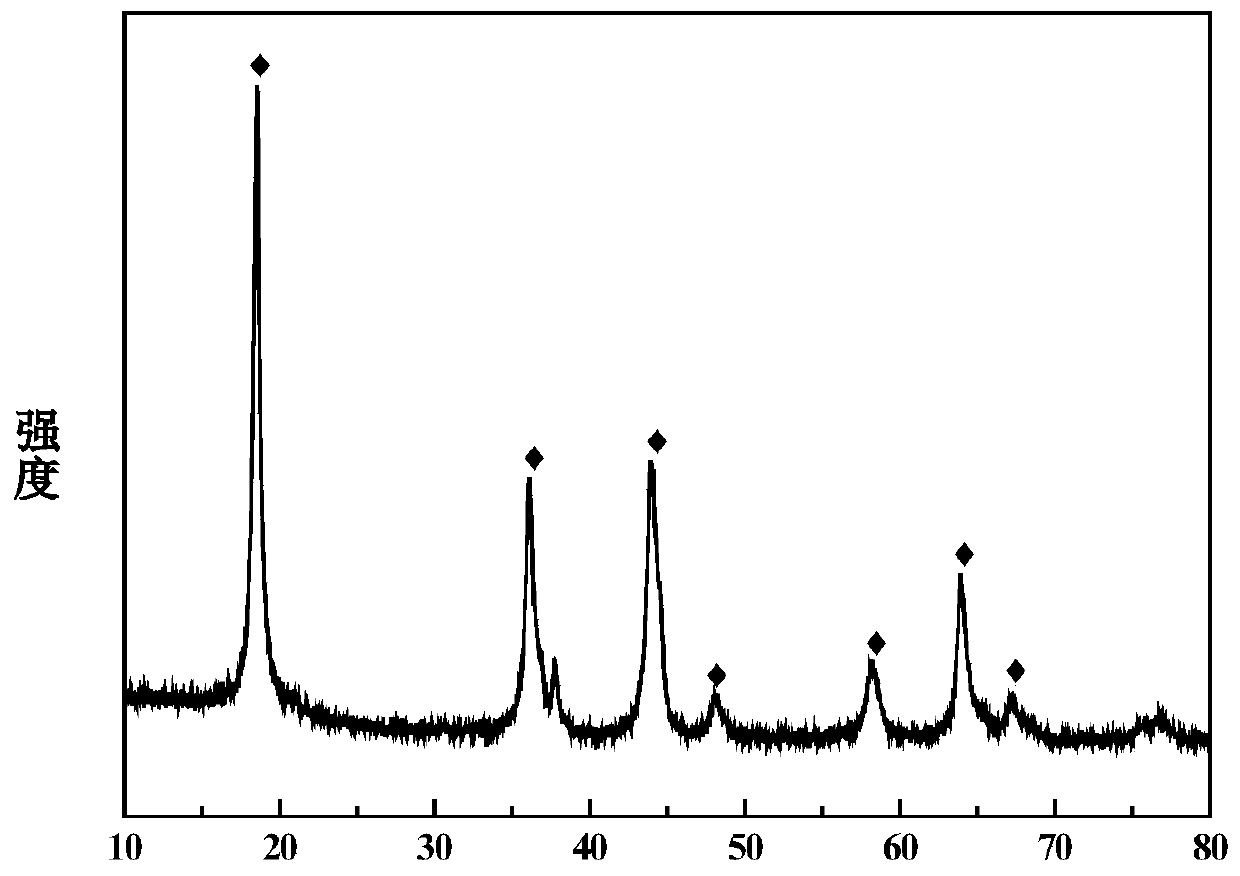

[0020] Embodiment 1: (gallium dosage x=0.2, gallium-manganese mixed solution ion concentration is 0.5mol / L, molar ratio Li + / (Mn 2+ + Ga 3+ )=4:1)

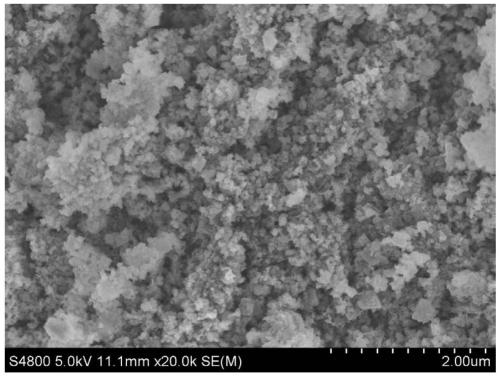

[0021] Weigh 0.0225mol of manganese chloride tetrahydrate and 0.0025mol of gallium nitrate hydrate, add 50mL of deionized water, stir until completely dissolved, and obtain a mixed solution of gallium and manganese. Weigh 0.1mol hydrated lithium hydroxide and add it to 50mL deionized water, after stirring for a period of time, add 4mL of 30% hydrogen peroxide solution and continue stirring until fully dissolved, then add the lithium solution dropwise to the above mixed solution at a rate of 5mL / min . After continuing to stir for a period of time, the black precipitate was transferred to a 200 mL polytetrafluoroethylene-lined reactor, and hydrothermally reacted at a temperature of 120° C. for 8 hours in an electric constant temperature blast drying oven. The product is filtered and ground to obtain the doped precursor LiGa 0....

Embodiment 2

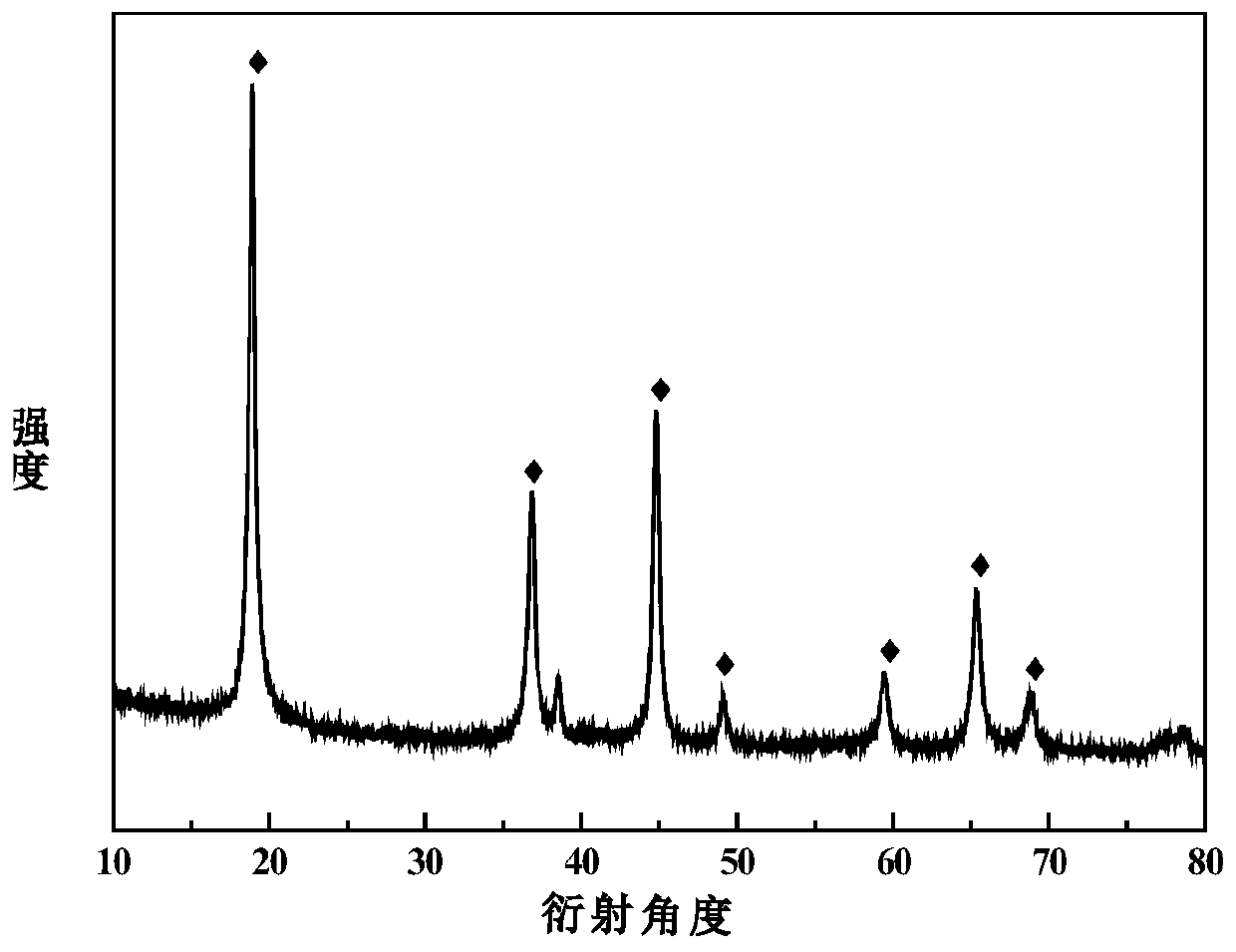

[0022] Embodiment 2: (gallium dosage x=0.3, gallium-manganese mixed solution ion concentration is 1mol / L, molar ratio Li + / (Mn 2+ + Ga 3+ ) is 5:1),

[0023] Weigh 0.0425mol of manganese carbonate and 0.0075mol of anhydrous gallium chloride, add 50mL of deionized water, stir until completely dissolved, and obtain a mixed solution of gallium and manganese. Weigh 0.25mol hydrated lithium hydroxide and add it to 50mL deionized water. After stirring for a period of time, add 5mL of 30% hydrogen peroxide solution and continue to stir until fully dissolved. Then add the lithium solution dropwise to the above mixed solution at a rate of 4mL / min. . After continuing to stir for a period of time, the black precipitate was transferred to a 200 mL polytetrafluoroethylene-lined reactor, and hydrothermally reacted at a temperature of 160° C. for 14 hours in an electric constant temperature blast drying oven. The product is filtered and ground to obtain the doped precursor LiGa 0.3 mn ...

Embodiment 3

[0024]Embodiment 3: (gallium dosage x=0.05, gallium-manganese mixed solution ion concentration is 3mol / L, molar ratio Li + / (Mn 2+ + Ga 3+ ) is 1:1)

[0025] Weigh 0.14625mol of manganese bromide and 0.00375mol of anhydrous gallium chloride, add 50mL of deionized water, stir until completely dissolved, and obtain a mixed solution of gallium and manganese. Weigh 0.15mol hydrated lithium hydroxide and add it to 50mL deionized water. After stirring for a period of time, add 8mL of 30% hydrogen peroxide solution and continue stirring until fully dissolved, then add the lithium solution dropwise to the above mixed solution at a rate of 1mL / min. . After continuing to stir for a period of time, the black precipitate was transferred to a 200 mL polytetrafluoroethylene-lined reaction kettle, and hydrothermally reacted at a temperature of 140°C for 10 h in an electric constant temperature blast drying oven. The product is filtered and ground to obtain the doped precursor LiGa 0.05 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com